Arctic-Temp® Ice Makers by Holiday Ice, Inc.

All Purpose Industrial Ice Machines From 2,500 to 10,000 lbs Per Day

Holiday Ice is a manufacturer of specialized, mid-range capacity commercial ice machines for industrial applications. For over 60 years, our commitment to personal service and outstanding quality has created a family of happy customers.

The Best Value

Our machines are efficient, economical, and made from the highest quality material and components, including top-of-the-line Copeland compressors.

Energy & Water Efficient

Our machines use re-circulated water, which saves you money on water costs. They also use less electricity than other models at the same capacity.

Realistically Rated

Our machines operate in Southern latitudes and are realistically rated for maximum performance during the scorching summer months when demand is greatest.

60+

years of experience

Who We Are

Holiday Ice,Quality You Can Count On.

Our Arctic-Temp® Ice Machines are legendary for providing years of reliable performance, even in the most grueling climates and conditions. Holiday Ice is a family-owned business, and we serve our customers with a personal touch.

Personalized Customer Service

Instead of some pre-recorded message, you’ll be greeted by a member of our friendly staff.

Top-Rated Copeland Compressors

No other manufacturer offers our combination of quality, longevity, price and service.

7000 Lbs Industrial Ice Machine

Table of Contents

Acquiring a 7000 lbs Industrial Ice Machine

In today’s demanding commercial landscapes, securing a reliable 7000 Lbs Industrial Ice Machine is essential for businesses like food processors and fisheries that require up to 7,000 pounds of crystal-clear ice daily to maintain operations without interruption.

As leading vertical tube ice machine manufacturers, Holiday Ice brings over 60 years of family-owned expertise to their Arctic-Temp models, featuring innovative vertical tube technology with double-walled evaporators and dependable Copeland compressors for superior efficiency and durability. Unlike bulkier block ice alternatives, such as the Emerson 15-ton (30,000 lbs) machine, Arctic-Temp’s design prioritizes serviceability and mid-range capacity tailored for U.S. buyers, ensuring faster production and easier maintenance.

This guide walks you through the process, from initial needs assessment and model selection to installation, operation, and troubleshooting, empowering you to integrate high-capacity tube ice makers seamlessly into your workflow.

Focus on Holiday Ice for pre-tested industrial ice production equipment, direct factory quotes, and nationwide support, including industrial ice maker servicing and parts to minimize downtime and maximize reliability–starting with models like the 500 sm-l industrial ice machine.

Assess Your Requirements Before Purchasing

Before investing in a 7000 Lbs Industrial Ice Machine, assess your operational needs to ensure optimal performance and cost efficiency. This step prevents mismatches in capacity or setup, saving time and money for businesses like fisheries or food processors requiring reliable high-volume ice production systems.

Use this checklist to evaluate key factors:

- Capacity: Calculate daily ice demands based on production volume. For a fishery processing 10,000 pounds of seafood daily, aim for at least 7000 lbs output to cover peak needs without shortages.

- Space: Measure installation area for vertical tube units, typically 8-10 feet high and 5-7 feet wide. Ensure clearance for airflow and maintenance access.

- Power Specs: Verify electrical requirements, such as 208-230V single-phase. Compare to competitors like the Manitowoc SY-3305W3 at 263HP; Holiday Ice models use efficient Copeland compressors for lower energy use and simpler setup.

- Integration: Check water supply (1/2-inch line) and ambient conditions (under 100°F). Plan for industrial ice maker servicing and parts availability, especially if replacing legacy equipment.

To calculate needs, multiply daily usage by a 20% buffer. A supermarket chain might require 7000 lbs for beverage cooling, factoring in summer spikes. Note these metrics for your quote request.

This assessment guides selecting the right Arctic-Temp model, like the arctic temp 500 sm-l ice maker, ensuring seamless fit and long-term reliability in your operations.

Research Vertical Tube Ice Machines

Start your research by reviewing specifications from trusted sources and comparing ice machine types online. Vertical tube ice machines, like those in Holiday Ice’s Arctic-Temp series, feature a unique vertical tube design with double-walled evaporators that utilize 100% of the surface area for freezing, unlike flake machines that produce continuous sheets or block types that form large, slow-melting cubes. Leading vertical tube ice machine manufacturers in the US, such as Holiday Ice with 60 years of expertise, integrate stainless steel construction and Copeland compressors for reliable tube ice production tech. In contrast to OMT cube machines, which use a different freezing method with partial surface contact, Arctic-Temp models eliminate moving parts in the freezing zone, ensuring lower maintenance and faster cycles through full-surface freezing, like wrapping each tube completely for quicker results.

This research matters because selecting the right technology guarantees efficient, durable equipment that reduces long-term costs. Arctic-Temp’s design maximizes heat exchange efficiency, enabling high-output models to produce up to 7000 Lbs Industrial Ice Machine capacity daily with minimal downtime and pre-tested performance for immediate use in industrial settings like food processing or fisheries.

Focus on US-based manufacturers for easy access to industrial ice maker servicing and parts. Verify output ratings, such as 7000 lbs per day, and consider standardized components available from refrigeration wholesalers. For example, the 750 sm-l industrial ice machine offers scalable production with simple diagnostics, streamlining your procurement process.

Explore Arctic-Temp Models

Holiday Ice’s Arctic-Temp series stands out among vertical tube ice machine manufacturers for its reliable, family-owned design tailored to industrial needs. These vertical tube ice machines emphasize durability with stainless steel construction, double-walled evaporators using 100% surface area for maximum efficiency, and integrated Copeland compressors for seamless operation. Key models include the 1000 AR-L (up to 1000 lbs daily), 1500 RCU (1500 lbs with remote condenser for flexible installation), and the robust 1500 SM-B (1500 lbs in a compact footprint). For higher demands, the arctic temp 750 sm-l ice maker scales effectively through combinations.

Scalable Arctic-Temp models for industrial ice production up to 7000 lbs

To reach a 7000 Lbs Industrial Ice Machine output, combine units like multiple 1500 SM-B models or customize larger configurations, ensuring efficiency without excess energy use. Unlike cube machines such as the Manitowoc ST-3000, Arctic-Temp’s tube design offers continuous production and easier servicing with standardized parts from refrigeration wholesalers, reducing downtime. Prioritize Copeland-integrated units for reliability; contact Holiday Ice for scaling advice and quotes to match your exact needs, including industrial ice maker servicing and parts support.

Request a Quote from Holiday Ice

Securing a personalized quote for your 7000 Lbs Industrial Ice Machine is simple and straightforward through Holiday Ice’s direct factory channels. As a family-owned U.S. manufacturer, Holiday Ice provides no-obligation direct manufacturer quotes that deliver competitive pricing without the import delays seen in international options, such as the Emerson 62.7kw model priced for overseas markets. This process ensures tailored solutions for your Arctic-Temp needs, transitioning seamlessly into installation planning.

To get started, follow these steps:

- Submit an Online Form: Visit the Holiday Ice website and complete the quote request form. Specify your required capacity (like 7000 lbs per day), installation location, and any integrations such as water treatment systems. Include details on your operation to receive accurate recommendations.

- Contact by Phone or Email: Call the dedicated 800-number at 800-554-1421 or email sales@holiday-ice.com for immediate discussion. Provide the same key information to expedite your request.

Expect a response within 24-48 hours, often faster for urgent needs. Quotes typically include customized pricing, delivery timelines, and comprehensive warranty coverage that encompasses industrial ice maker servicing and parts for long-term reliability. For models like the 750 ar-l industrial ice machine, inquire about bundle options.

Why Request a Quote Now? Holiday Ice’s U.S.-based customization offers faster turnaround and better value than imported alternatives, providing exact figures for your 7000 lbs setup to drive quick decisions.

Pro Tips: Attach site photos to your submission for precise advice, and ask about service bundles to optimize costs from the start.

Plan Your Installation

Installing a 7000 Lbs Industrial Ice Machine requires careful planning to achieve reliable operation in demanding environments like food processing or fisheries. As trusted vertical tube ice machine manufacturers, Holiday Ice offers expert guidance and support, including coordination with certified professionals, to simplify the process and address queries like “How to install a 7000 lbs industrial ice machine?”

Begin with site preparation by evaluating space layout for the vertical tube design, which contrasts with more complex setups like OMT’s cube machines by easing placement due to its simple, durable structure. Ensure at least 10 feet of clearance around the unit for maintenance access. Next, prepare utilities: connect a consistent water supply (at least 1/2-inch line), 208-230V three-phase power compliant with the machine’s 30-50 amp draw, and a floor drain or pump for efficient wastewater removal. Hire certified installers experienced in industrial refrigeration to handle connections, ensuring compliance with local building codes and OSHA safety standards, such as proper grounding to prevent electrical hazards.

Step-by-step installation guide for vertical tube industrial ice machines

This structured approach guarantees safe, efficient operation, minimizing downtime and maximizing the machine’s 100% evaporator efficiency for rapid ice production. Post-installation testing, including a full cycle run, verifies performance and identifies issues early.

Key tips include confirming Copeland compressor compatibility with your power setup and conducting an on-site test under load conditions. Holiday Ice’s team assists throughout, from parts sourcing for industrial ice maker servicing and parts to final walkthroughs, just as with our arctic temp 750 ar-l ice maker models scaled for larger capacities.

Arrange Servicing and Parts

To ensure the longevity and optimal performance of your 7000 Lbs Industrial Ice Machine, arranging reliable servicing and parts support is essential. Holiday Ice, with over 60 years of expertise, offers a fully stocked parts department featuring standardized components like Copeland compressors, compatible with models such as the 1000 ar-l industrial ice machine and arctic temp 1000 ar-l ice maker. Begin by setting up a service calendar for routine maintenance–recommend quarterly inspections for high-capacity units to match or exceed Manitowoc’s guidelines, preventing issues like evaporator scaling or compressor strain. Order replacement parts online through our portal or via phone for quick delivery, minimizing downtime during peak production.

This proactive approach prevents costly breakdowns and maintains consistent ice output. By addressing common issues early, such as refrigerant leaks or ventilation blockages, you avoid emergency repairs that could halt operations for days.

Stock essential spares like filters and gaskets in advance, and leverage our phone support for instant troubleshooting. Our team provides step-by-step guidance, ensuring minimal disruption and full access to resources for seamless upkeep.

Verify Capacity and Performance

After setup and initial servicing, verifying the capacity and performance of your arctic temp 1500 sm-b ice maker ensures it delivers the promised 7000 lbs of ice per day. Holiday Ice pre-tests every unit to guarantee reliability, drawing on over 60 years of expertise as leading vertical tube ice machine manufacturers. Start by monitoring the first few runs: power on the machine and observe the freezing cycle for consistent tube formation.

Measure output rates by collecting ice over a 24-hour period under normal operating conditions, aiming for the full 7000 lbs from your 1500 sm-b industrial ice machine. Test under load by simulating peak demand, such as continuous harvesting, to confirm efficiency without strain. Document metrics like cycle time and energy use to track performance.

This verification confirms return on investment by validating the machine’s robust output, far surpassing benchmarks from competitors like Emerson models that often vary in delivery. Consistent 7000 lbs production minimizes downtime and maximizes productivity for industrial needs.

Log all data in a performance journal, noting any deviations for reference during industrial ice maker servicing and parts maintenance. If adjustments are needed, consult the factory directly for tailored guidance, ensuring long-term reliability and supporting an average lifespan of 20+ years through proactive monitoring.

Finalize Purchase and Delivery

Securing your 7000 Lbs Industrial Ice Machine from Holiday Ice marks the exciting culmination of your search for reliable industrial ice production. Begin by reviewing the detailed quote, which includes essential industrial ice maker servicing and parts for long-term performance. Process payment securely through Holiday’s encrypted platform, ensuring compliance with industry standards as a trusted vertical tube ice machine manufacturers. Sign the contract digitally to lock in your order.

Coordinate delivery with Holiday’s nationwide efficiency, far surpassing competitors like OMT by offering tracked shipments and flexible scheduling. Track your 1000 sm-l industrial ice machine or larger model via the provided portal for real-time updates.

This process secures timely operation, minimizing downtime and ensuring your facility runs smoothly from day one. Upon arrival, inspect the arctic temp 1000 sm-l ice maker or equivalent for damage, then initiate the warranty by contacting support. Insure the shipment against transit risks and prepare your site with adequate space and utilities for seamless installation.

Addressing Common Challenges in Ice Machine Operation

Operating a 7000 Lbs Industrial Ice Machine demands attention to potential hurdles, especially in vertical tube designs like Arctic-Temp models such as the 5000 Lbs Industrial Ice Machine. Common issues such as reduced output or mechanical faults can arise post-installation, but Holiday Ice’s resources ensure minimal downtime. Proactive troubleshooting keeps production steady for demanding applications.

- Low Output: If ice production drops below rated capacity in your 7000 Lbs Industrial Ice Machine, suspect water quality issues like high mineral content. Cause: Scale buildup clogs tubes, reducing freeze efficiency. Steps: Test water hardness; install a softener if over 100 ppm. Flush the system with a vinegar solution, then resume operation to restore full yield.

- Compressor Faults: Should the compressor cycle erratically, it signals electrical overload or refrigerant leaks, differing from complex cube machines like Manitowoc’s. Arctic-Temp’s simpler mechanics aid quick diagnosis. Check voltage supply; if low, adjust breakers. Inspect for oil leaks and top off refrigerant per specs to prevent further strain.

- Evaporator Scaling: Scaling on vertical tubes hampers heat transfer, akin to challenges in high-capacity Emerson units. If ice forms unevenly, hard water is the culprit. Clean with a descaler monthly; monitor for residue. Prevention mirrors Emerson tips: Use filtered water to extend evaporator life and maintain consistent output.

- Electrical Issues: Faulty wiring or sensors can halt the 6000 Lbs Industrial Ice Machine. Symptom: No power to controls. Verify connections; replace blown fuses. For tube ice troubleshooting, consult Holiday Ice manuals for circuit diagrams to safely isolate faults.

- Tube Ice Troubleshooting: Warped tubes from overheating cause jamming. Inspect for blockages; thaw gently if needed. Arctic-Temp’s design minimizes this with durable stainless construction.

Prevention starts with routine checks: Weekly water tests, monthly cleaning, and annual industrial ice maker servicing and parts inspections. Stock common filters and gaskets from Holiday Ice’s warehouse for swift swaps, ensuring longevity in vertical tube systems.

When persistent issues emerge, contact Holiday Ice’s family team for phone-based diagnostics. Describe symptoms like error codes or noise levels; technicians guide remote fixes or arrange parts overnight. This direct support, honed over 60 years, resolves most problems without on-site visits, keeping your operation ice-ready.

Completing Your Industrial Ice Solution

Achieve seamless operations with a 7000 Lbs Industrial Ice Machine from Holiday Ice, leveraging Arctic-Temp vertical tube technology for unmatched reliability. This solution delivers fast production rates, maximizing heat exchange efficiency through double-walled evaporators that utilize 100 percent of the surface area. As leading vertical tube ice machine manufacturers, we emphasize simple designs with fewer moving parts, ensuring easy maintenance and a long lifespan–superior to alternatives like OMT systems by reducing component needs and downtime. Our 60-year expertise guarantees robust stainless steel construction and Copeland compressors for sustained performance in demanding environments.

Your journey begins with a tailored assessment of needs, progressing through procurement, expert installation, and comprehensive training. From initial setup to routine industrial ice maker servicing and parts support, Holiday Ice provides direct factory assistance, including stocked components and phone-based troubleshooting for minimal interruptions.

Looking ahead, this reliable industrial ice systems empowers your business with continuous ice production, boosting efficiency in food processing, fisheries, or bottling. With these steps, you’re equipped for efficient ice making–now secure your Arctic-Temp solution directly. Request a no-risk quote today to experience our factory expertise and nationwide delivery tailored to your operations.

Resources

5000 Lbs Industrial Ice Machine 6000 Lbs Industrial Ice Machine

What We Offer

OurIce Machines

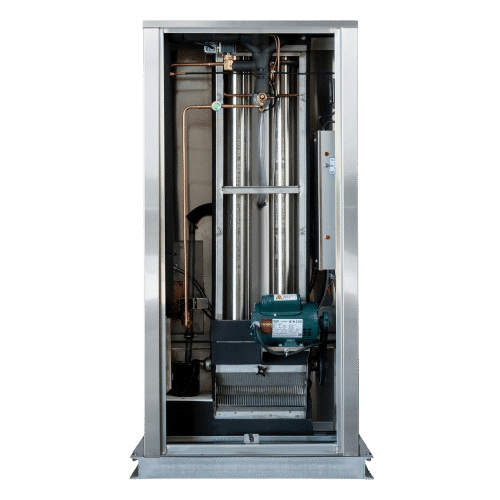

ARCTIC-TEMP® MODEL 500

- 2,500 lbs. of hard cracked ice in 24hrs. (907 Kg.)

- Highly efficient Copeland Compressor

- Double-Walled Vertical Tube Evaporators For Maximum Production

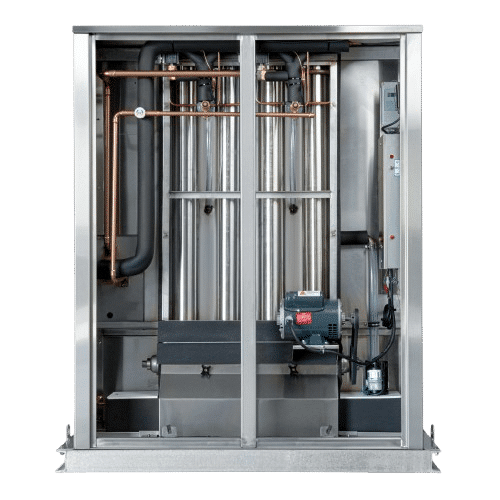

ARCTIC-TEMP® MODEL 750

- 4,500 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

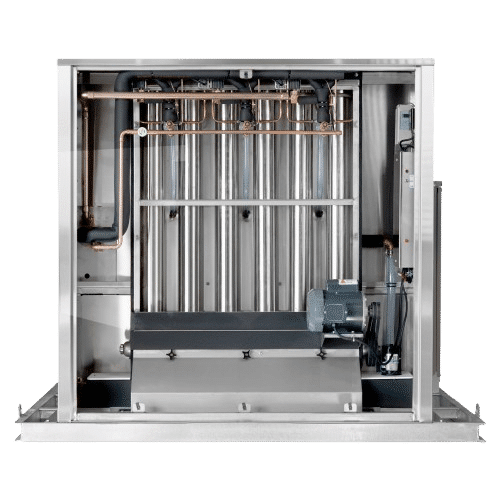

ARCTIC-TEMP® MODEL 1000

- 6,500 lbs. of hard cracked ice in 24 hrs. (2,948 Kg.)

- Highly efficient Copeland Discus Compressor

- Double-Walled Vertical Tube Evaporators

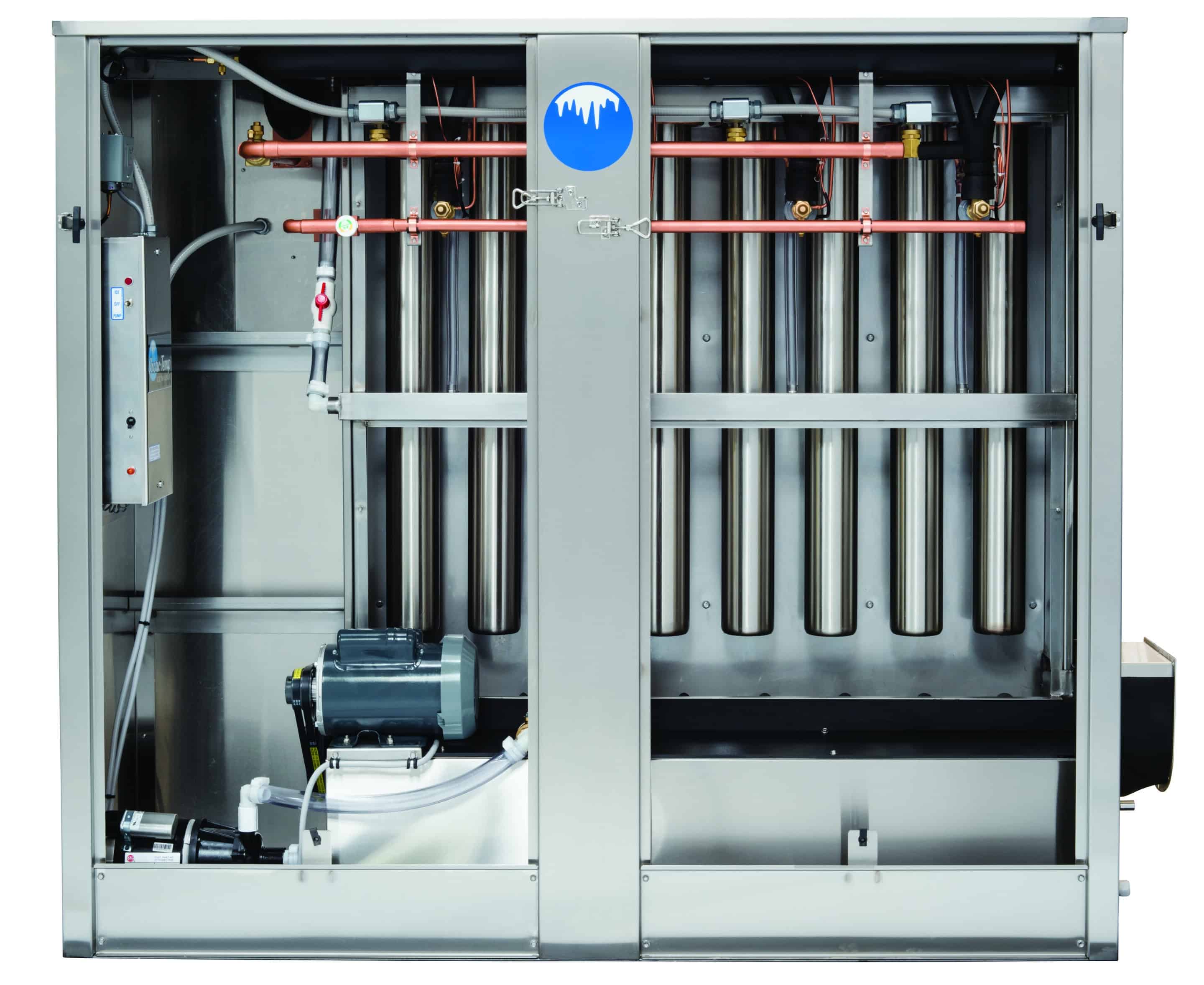

ARCTIC-TEMP® MODEL 1500

- 10,000 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

Ice Machine Manufacturing

ProductionProcess

- Our ice machines are built using high-quality Type-304 stainless steel, unlike other companies that use lower-grade alloys.

- Machines are hand-assembled and TIG welded for precision.

- Stainless steel evaporators are hand-formed and welded for durability.

- The ice-making section is fully assembled before being combined with the condenser and compressor.

- We use COPELAND compressors, known for their quality, industry-leading warranty, and widespread parts distribution.

- Our evaporators use a double-surface concave freezing technique with vertical tubes for faster, more efficient ice production and improved cooling.

- The freezing zone contains no moving parts, avoiding issues related to gears or motors.

- Standard, easily replaceable components are used, except for the evaporator, which simplifies maintenance after the warranty period.

- All machines are leak and vacuum tested, factory charged with refrigerant, and thoroughly calibrated for reliable performance from the start.

Years in Business

Ice Machines Sold

Repeated Customers

Countries Served

Global Network

CountriesWe Serve

North America

- • USA

- • Canada

- • Mexico

- • Bahamas

- • Anguilla

- • Cayman Islands

- • Jamaica

- • Dominican Republic

- • St. Lucia

Central America

- • Belize

- • Honduras

- • Nicaragua

- • Guatemala

- • El Salvador

South America

- • Guyana

- • Suriname

- • Ecuador

South America

- • Guyana

- • Suriname

- • Ecuador

Aruba

Iceland

Philippines

Oceania

- • American Samoa

- • Australia

Client Reviews

Testimonials

Discover firsthand experiences from our satisfied customers about their Arctic-Temp® ice machines.