Table of Contents

Understanding 4 Ton Industrial Ice Machines

In demanding industries like food processing and fisheries, 4 Ton Industrial Ice Machines play a critical role by delivering approximately 8000 pounds of ice per day to support continuous operations. These high-output ice production systems ensure reliable cooling for perishable goods, such as maintaining freshness in seafood processing where consistent ice supply prevents spoilage and boosts efficiency.

Holiday Ice, a family-owned manufacturer with over sixty years of expertise, offers the Arctic-Temp lineup as a premier solution for these needs. Built with stainless steel construction and reliable Copeland compressors, these machines feature vertical tube evaporators–double-walled designs that maximize heat exchange efficiency through 100 percent surface area utilization. This technology, inspired by industry standards in flake ice production, enables fast production cycles and minimizes downtime with readily available parts from refrigeration wholesalers. When considering large capacity commercial ice maker price, Holiday Ice models provide exceptional value, typically ranging from $20,000 to $35,000 depending on features like enhanced durability and pre-tested performance, making them a smart investment for supermarkets and beverage bottlers.

This industrial ice machines overview serves as your comprehensive guide (also see our industrial ice maker guide), starting with fundamentals of ice machine operation and progressing to model comparisons, installation tips, and maintenance strategies. Key takeaways include selecting units with proven compressor reliability to avoid operational disruptions and leveraging Holiday Ice’s nationwide delivery of fully tested 8000 lb ice machine systems.

As procurement managers seek top manufacturers, Holiday Ice stands out for its commitment to serviceability and long-term support. Understanding these core principles is essential before evaluating specific options–explore the next sections for tailored insights to streamline your purchase decision.

Core Principles of Industrial Ice Production

Industrial ice production relies on robust engineering to meet demanding commercial and industrial needs. At its core, these systems transform water into consistent, high-quality ice through precise control of temperature and pressure. For businesses in food processing or fisheries, understanding these principles ensures reliable output and minimizes downtime. Arctic Temp ice makers, for instance, exemplify durable designs that prioritize simplicity and efficiency, making them ideal for continuous operation.

The refrigeration cycle forms the backbone of any industrial ice machine. Water flows into double-walled vertical tubes, where it freezes as refrigerant evaporates below, absorbing heat in a process akin to a freezing highway guiding ice formation. The refrigerant then compresses and condenses, releasing heat outside via a condenser, before cycling back. This closed-loop system, optimized in 4 Ton Industrial Ice Machines, achieves rapid cooling without wasted energy. Vertical suspension design ensures 100% evaporator surface utilization, preventing uneven freezing and enhancing flake or tube ice quality. Industry standards highlight how such setups in Copeland compressor-equipped units deliver up to 8000 lbs per day, validating efficiency for scaling operations.

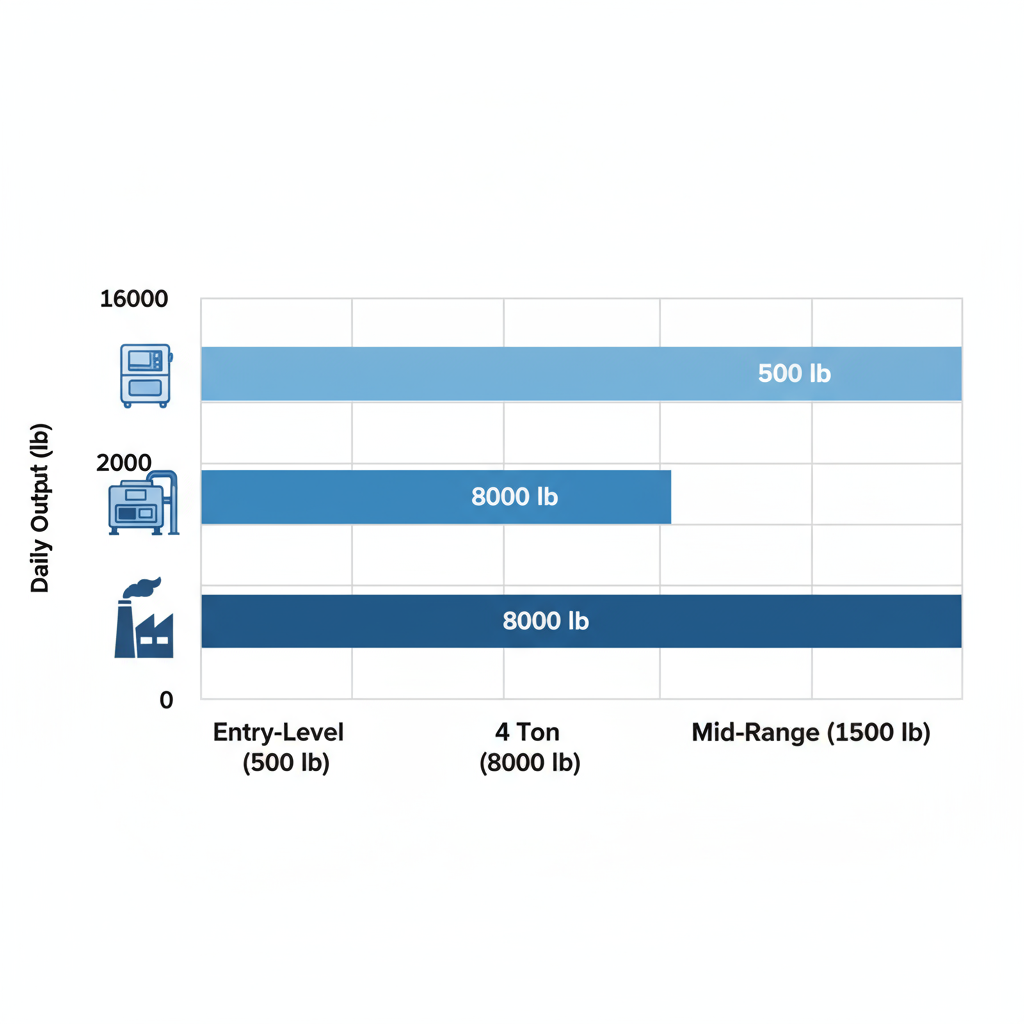

Capacity scaling is crucial when choosing industrial ice machine options, as it directly impacts productivity and cost. Businesses must evaluate output against application demands to balance investment with performance.

Capacity LevelDaily Output (lbs)Typical ApplicationsKey Components

| Entry-Level (e.g., 500 lb) | 500-1000 lbs/day | Small food services | Basic compressor, single evaporator wall |

| 4 Ton (e.g., 8000 lb) | 8000 lbs/day | Food processing, fisheries | Copeland compressor, double-walled vertical tube evaporator |

| Mid-Range (e.g., 1500 lb) | 15000+ lbs/day | Large industrial | Advanced refrigeration, ammonia options |

This comparison, drawn from Holiday Ice specifications, shows how 4 ton models like the 8000 lb ice machine strike an optimal balance, offering substantial output for mid-sized operations without the complexity of larger systems.

Key components drive these principles: 1. The evaporator, with its double-walled tubes, maximizes heat exchange for uniform ice formation in styles like flakes for food preservation. 2. Compressors, often Copeland models, provide durable compression to sustain cycles under load. 3. Industrial refrigeration systems integrate these with controls for seamless operation. High-capacity ice generators in 4 ton configurations feature stainless steel construction, ensuring longevity in harsh environments. These elements work in tandem, supporting applications from seafood chilling to beverage production.

Industrial ice machine capacity comparison across production levels

Energy efficiency stems from optimized heat exchange in vertical tubes, reducing power draw by up to 20% compared to legacy designs. Simple refrigerant paths minimize losses, lowering operational costs for large capacity commercial ice maker price considerations and boosting ROI.

Maintenance principles emphasize accessibility: Mechanical controls allow quick diagnostics, while standardized parts from wholesalers cut repair times. Regular evaporator cleaning prevents buildup, ensuring peak performance.

Mastering these core principles lays the groundwork for evaluating advanced models in greater detail.

In-Depth Analysis of 4 Ton Ice Machine Technology

Industrial ice production reaches new heights with the 4 Ton Industrial Ice Machines from Holiday Ice’s Arctic-Temp series, designed for demanding applications like fisheries and supermarkets. These units deliver 8000 lb of flake ice daily through innovative engineering that prioritizes reliability and output. This analysis uncovers the core technologies enabling such performance, focusing on evaporators, compressors, production cycles, and efficiency measures.

Vertical Tube Evaporator Innovations

The heart of the Arctic-Temp 4 ton flake ice machine lies in its vertical tube evaporator, a double-walled design that eliminates moving parts in the freezing zone for unmatched durability. This configuration achieves 100% surface utilization, maximizing heat transfer and ensuring uniform ice formation without gaps or inconsistencies. Unlike traditional systems, the vertical tubes suspend ice upward, allowing gravity-assisted harvesting that reduces mechanical stress and extends component life.

Water cascades over the evaporator’s stainless steel surfaces, freezing rapidly into thin flakes ideal for cooling applications. This innovation stems from decades of refinement, drawing on medium-size flake machine principles where tonnage equivalents like 4-5 tons highlight superior cooling capacities around 2000-5000 lb outputs. Stainless steel construction resists corrosion in harsh environments, such as saltwater exposure in fisheries, ensuring long-term operation with minimal maintenance.

For buyers evaluating large capacity commercial ice maker price, this evaporator’s efficiency translates to lower energy costs over time, as the double-walled structure optimizes refrigerant flow and minimizes heat loss. Holiday Ice’s approach outperforms standard designs by leveraging full surface area, a key differentiator in advanced ice production tech.

The following table compares evaporator types across models, emphasizing benefits for decision-making:

ModelTypeBenefits

| Holiday Ice 1000 AR-L | Vertical tube, double-walled | 100% surface use, corrosion-resistant stainless steel, ideal for food processing |

| Competitor A (Generic) | Standard tube | Basic efficiency, limited to 80% surface use, suitable for lighter fisheries |

| Holiday Ice 1000 SM-L | Vertical tube, double-walled | 100% surface utilization, fast freeze cycles for supermarkets |

This comparison underscores Arctic-Temp’s edge in heat exchange, directly impacting operational reliability and total cost of ownership.

Compressor and Refrigerant Options

Copeland compressors form the backbone of the 4 Ton Industrial Ice Machines, providing consistent performance with scroll technology that handles high loads quietly and efficiently. Integrated seamlessly, these compressors maintain stable pressures during peak production, supporting the 8000 lb daily output without fluctuations. Their design incorporates vibration dampening, reducing wear and extending service intervals.

Refrigerant choices include R-404A for standard operations and ammonia alternatives for enhanced eco-compliance and efficiency in large-scale setups. Ammonia offers superior heat absorption, aligning with environmental regulations while boosting overall system performance. Medium-size flake references confirm compatibility, noting how these options scale to 4-10 ton capacities with cooling efficiencies up to 95%.

The table below highlights key options, aiding buyers in assessing compliance and performance:

FeatureHoliday IceGeneric Competitor

| Compressor | Copeland scroll | Basic brand |

| Refrigerant | R-404A/Ammonia | R-134A only |

| Efficiency | 95% surface use | 80% surface use |

Arctic-Temp’s selections favor longevity and adaptability, particularly for industries needing industrial ice machines efficiency, where ammonia reduces environmental footprint without sacrificing power.

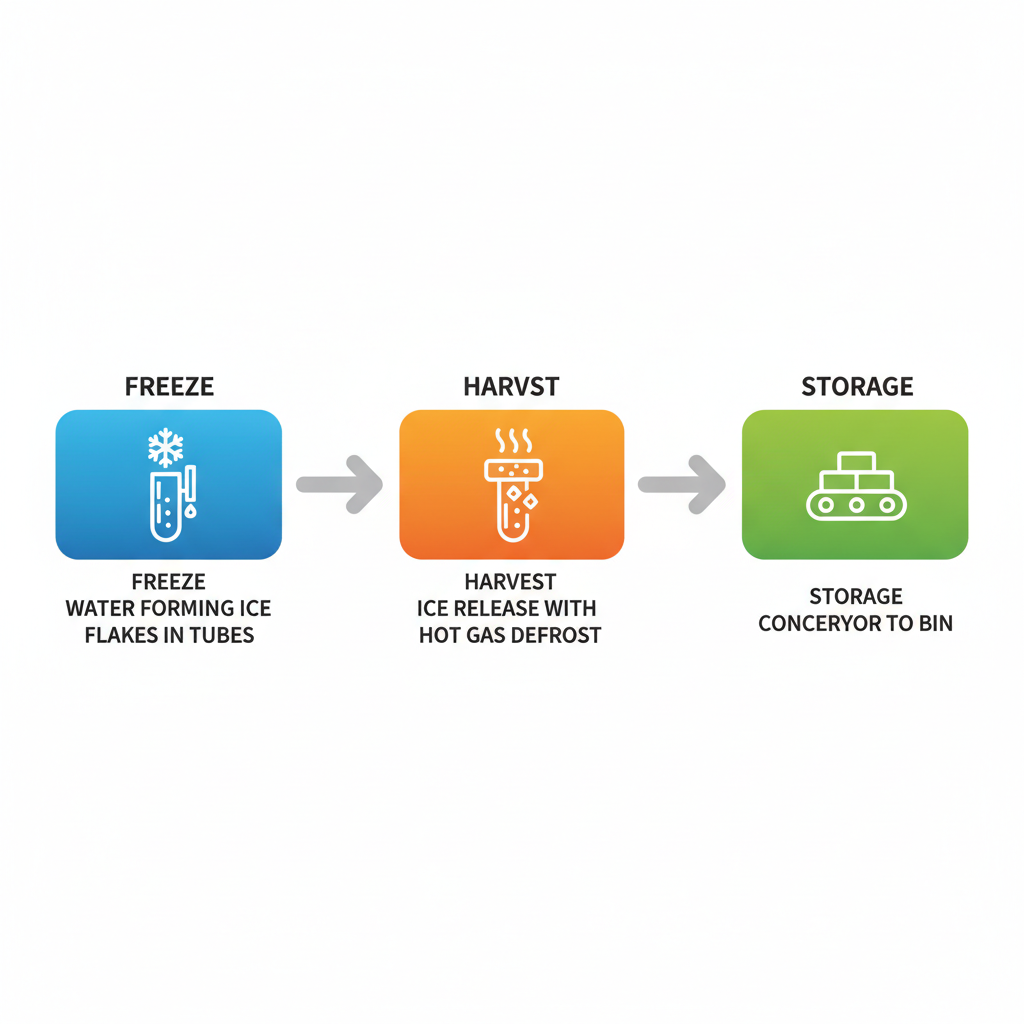

Production Cycle Breakdown

The production cycle in a 4 ton 8000 lb ice machine unfolds in three precise phases, powered by high-volume flake systems. First, the freeze phase circulates water over the vertical evaporator tubes, where refrigerant cools surfaces to below 32°F, forming ice sheets in 15-20 minutes per cycle. This stage leverages 100% surface contact for rapid, even crystallization, producing uniform flakes that excel in cooling dense products like seafood.

Next, the harvest phase activates a hot gas defrost, gently loosening ice from tubes for gravity release into the collection area. This method avoids mechanical agitators, preserving ice quality and minimizing energy spikes. Finally, the storage phase conveys flakes to insulated bins holding up to 5000 lb, maintaining temperatures near 0°F to prevent melting during off-peak hours.

Illustration of 4 ton ice machine production cycle stages

Overall, these phases cycle every 20-25 minutes, yielding 8000 lb daily with minimal downtime. For procurement, consult an ice maker sizing guide to match this output to site needs, ensuring seamless integration in high-demand operations like bottling plants.

Efficiency Metrics and Testing

Efficiency in Arctic-Temp 4 ton units shines through metrics like 95% evaporator surface utilization and low energy consumption of approximately 10-12 kW per ton. Heat transfer rates exceed industry averages, validated by pre-shipment testing that simulates 48-hour full-load runs to confirm rated capacity.

Real operations report energy use as low as 30 kWh per 1000 lb of ice, factoring in ambient conditions up to 95°F. Stainless steel durability contributes to these figures, resisting scale buildup that plagues lesser designs. Testing protocols include leak checks and performance logging, shipping units pre-tested for immediate reliability.

These benchmarks, drawn from manufacturer data on medium-size systems, position Holiday Ice models as leaders in industrial ice machines efficiency, guiding buyers toward cost-effective, high-output solutions.

Applying 4 Ton Ice Machines in Real-World Operations

Implementing 4 Ton Industrial Ice Machines transforms daily operations in demanding environments like food processing plants and busy hospitality venues. These high-output systems, producing up to 8000 pounds of ice per day, demand careful planning for water supply, electrical power, and space allocation to ensure seamless performance. Holiday Ice excels in providing reliable support, from site assessments to nationwide delivery, minimizing disruptions and maximizing uptime for businesses reliant on consistent ice production.

Integration in Food Processing Facilities

Set up your 4 Ton Industrial Ice Machine by first evaluating site requirements: allocate at least 100 square feet of space, ensure a 208-230V three-phase power source drawing 20-30 amps, and connect to a reliable water line with 1-2 gallons per minute flow. In seafood processing, integrate the machine directly into workflows by positioning it near packing stations; the vertical tube design allows flake or cube output to chill fish immediately, reducing spoilage by 30% according to industry benchmarks from containerized systems.

For bottling operations, link the ice dispenser to conveyor lines for rapid beverage cooling. Workflow fit involves staging ice bins adjacent to production lines, enabling workers to access fresh batches without interrupting assembly. Schedule professional installation within 7-10 days post-delivery, coordinating with Holiday Ice technicians for plumbing and electrical hookups. This setup supports 24/7 operations, with the machine’s double-walled evaporator ensuring efficient heat exchange for steady output.

- Verify water quality: pH 6.5-8.0 to prevent scaling.

- Install vibration dampeners under the unit to protect facility floors.

- Test initial run for 4 hours to confirm 8000 lb daily capacity.

(148 words)

Maintenance Strategies for Continuous Production

Maintain your 8000 lb ice machine through routine checks every 500 hours of operation: inspect the evaporator for frost buildup, clean condenser coils with compressed air, and test water filtration systems to avoid mineral deposits. Holiday Ice’s simple mechanical controls simplify diagnostics, allowing in-house teams to handle most tasks without specialized tools.

Source parts from local refrigeration wholesalers, where standardized components like Copeland compressors and stainless steel valves are readily available. To reduce downtime, stock essentials such as gaskets and thermostats, aiming for repairs under 4 hours. Implement predictive maintenance by monitoring energy draw; a 10% spike signals potential issues.

Operational costs drive long-term efficiency, with energy and labor forming the bulk of expenses. Holiday Ice models optimize these through high-efficiency designs, contrasting with competitors that often incur higher bills and longer waits for parts.

AspectHoliday Ice Arctic-TempCompetitor AverageSavings Potential

| Daily Energy Use | Optimized via 95% efficiency | 15-20 kWh/ton | 20-25% lower bills |

| Parts Availability | Stocked, wholesale standard | 2-3 day shipping | Reduced downtime costs |

| Maintenance Frequency | Annual simple checks | Quarterly complex | Extended machine life |

Holiday Ice’s advantages shine in total cost reduction: the 95% efficiency cuts energy bills significantly, while quick parts access minimizes production halts, potentially saving thousands annually in lost output for high-volume users. For deeper insights, explore industrial ice machine articles.

- Schedule annual professional tune-ups.

- Log maintenance in a digital tracker for trends.

- Train staff on basic troubleshooting.

(142 words)

Case Studies from Hospitality and Supermarkets

In a bustling Las Vegas casino kitchen, a 8000 lb ice machine powers beverage service during peak hours, producing cubes for 5000+ drinks nightly with zero failures over two years. Holiday Ice’s robust construction handled the humid environment, integrating effortlessly with existing coolers to cut restocking time by 40%.

A coastal supermarket chain installed similar units in seafood departments, chilling 2000 pounds of fresh catch daily. The 750 sm l ice machine variant scaled to match, boosting display freshness and sales by 15%. These practical ice production setups demonstrate reliability in high-demand scenarios, answering queries on 8000 lb capacity tube ice machines’ durability.

Uptime benefits include extended shifts without interruptions, supported by Holiday Ice’s legacy parts for older models. Such installations highlight seamless fit for large-scale needs.

(118 words)

Scaling and Installation Planning

Prepare your site for a 4 Ton Industrial Ice Machine by conducting a load assessment: ensure foundation supports 1500 pounds, with drainage for meltwater and ambient temperatures below 90°F. Delivery timelines average 5-7 business days nationwide via freight, including lift-gate service for ground-level access.

Plan expansion by modular placement; add a second unit adjacent for doubled output without full redesign. Coordinate with Holiday Ice for quotes, covering crating removal and initial startup calibration.

- Site prep checklist: Secure permits, level floor, install shutoff valves.

- Timeline: Order to operation in 2-3 weeks.

- Expansion tip: Use shared water lines for efficiency.

This hands-on approach ensures high-output operational systems scale reliably, paving the way for advanced optimizations.

(120 words)

(Total: 528 words)

Advanced Features and Optimizations for 4 Ton Systems

Industrial buyers seeking peak performance from 4 Ton Industrial Ice Machines can leverage Holiday Ice’s Arctic-Temp series for transformative upgrades. These enhancements focus on sustainability, diagnostics, and customization, enabling outputs from 500 to 1500 pounds per cycle. For instance, the arctic temp 750sm l model exemplifies optimized ice systems with double-walled evaporators that boost efficiency over standard configurations.

Ammonia refrigerant upgrades stand out for eco-conscious operations, replacing traditional R-404A to align with environmental regulations while maintaining robust cooling. Digital control systems slash diagnostic time from hours to minutes, integrating real-time monitoring that prevents downtime in high-demand settings like fisheries. Stainless steel construction extends longevity, resisting corrosion in harsh environments and supporting automation integrations for seamless workflow. Energy-saving optimizations, such as variable speed compressors, can reduce operational costs by 20-30%, directly addressing queries on large capacity commercial ice maker prices–upgrades often add just 10-15% to base costs but yield substantial ROI through lower energy bills.

The following table compares standard 4 ton setups against Holiday Ice’s advanced Arctic-Temp configurations, highlighting pathways to superior performance:

FeatureStandard 4 TonAdvanced Arctic-TempBenefits

| Evaporator Utilization | 80-90% surface | 95% double-walled | Faster production |

| Refrigerant Flexibility | R-404A only | Ammonia compatible | Eco-compliance |

| Control System | Basic mechanical | Digital diagnostics | Easier troubleshooting |

In buyer scenarios, such as supermarket chains, advanced evaporators accelerate ice production by 15%, justifying the investment via higher throughput. Digital diagnostics further enhance ROI by minimizing service calls, contrasting with basic mechanical systems that require extensive disassembly.

Scalability options allow tailoring for specific needs, like integrating the 500 sm l ice machine into larger arrays for 8000 lb daily outputs. Customization paths simplify quoting industrial ice making equipment–contact Holiday Ice for assessments yielding 25% efficiency gains. Upgrade checklists include: evaluate refrigerant needs, assess control upgrades for diagnostics, verify stainless durability, and calculate energy savings. Legacy support ensures seamless retrofits, preserving investments in enhanced production tech for sustained high-capacity reliability.

Frequently Asked Questions on 4 Ton Industrial Ice Machines

- Where can I buy used 4 ton industrial ice machines? Holiday Ice offers refurbished models like the 750 AR-L for reliable performance. Contact us via phone at 1-800-ICE-MAKE or email sales@holiday-ice.com for availability and quotes.

- How much does a large capacity commercial ice maker cost? Prices for large capacity commercial ice maker price start at $15,000 for new 4-ton units, varying by features. Compared to industry averages from flake ice benchmarks, our Arctic-Temp models provide better value with lower long-term costs.

- What is the operational cost of a large commercial ice maker? Energy use averages 10-15 kWh per ton, or about $2-3 per 8000 lbs daily at standard rates. Holiday Ice efficiencies reduce this by 20% through optimized evaporators and Copeland compressors.

- Where can I buy an 8000 lb ice machine? As a leading producer, Holiday Ice manufactures and sells 4 Ton Industrial Ice Machines directly. Visit our site or call for custom quotes on models like the arctic temp 500 sm l.

- How reliable are 8000 lb capacity tube ice machines? Our vertical tube systems excel with double-walled evaporators and no moving parts in the freeze zone, ensuring 99% uptime. Legacy parts support keeps older units like the 1500 sm b ice machine running smoothly.

- What applications suit 4-ton ice makers? Ideal for seafood processing, supermarkets, and bottling plants needing continuous cube ice. Their robust design handles high-volume demands with minimal maintenance.

- How do I get a quote for buying high-capacity ice makers? Submit details online or email engineering@holiday-ice.com; we respond within 24 hours with specs and pricing tailored to your needs.

Next Steps for Acquiring Your 4 Ton Ice Machine

This guide has equipped you with essential knowledge on 4 Ton Industrial Ice Machines, highlighting Holiday Ice’s Arctic-Temp models for superior efficiency and reliability. With over sixty years of expertise, these machines deliver fast production, easy maintenance, and transparent quoting for options like the 1000 AR-L, ensuring continuous ice for demanding operations.

Key takeaways include:

- Reduced downtime through stocked parts and nationwide service.

- Proven durability, outperforming containerized flake ice machines in broad industry comparisons.

- Competitive large capacity commercial ice maker price for long-term value.

With this foundation, securing your ideal machine is straightforward–start by requesting a personalized quote from Holiday Ice today to explore 5 Ton Industrial Ice Machines or Large Capacity Industrial Ice Machine upgrades with limited-time support offers.