Choosing the right industrial ice maker is crucial for any large-scale operation that relies on a steady supply of ice for cooling, storage, or processing. Whether your facility handles seafood, produce, meat, poultry, or other temperature-sensitive products, your ice machine directly impacts both efficiency and profitability.

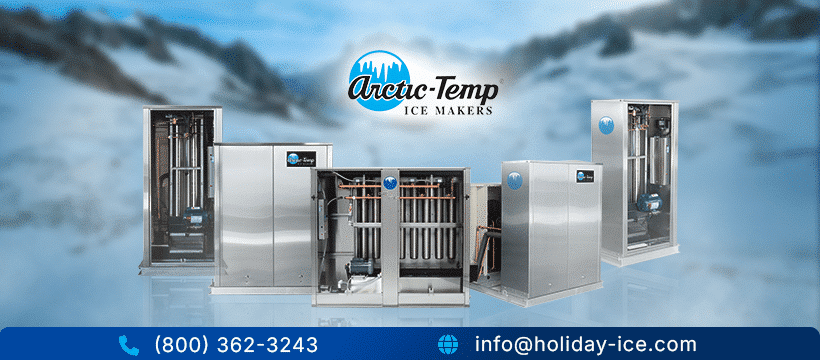

Holiday Ice Inc., the manufacturer of Arctic-Temp® vertical tube industrial ice machines, is here to help you understand what to look for when selecting equipment for your operation.

What Type of Industrial Ice Maker Do You Really Need?

Many types of commercial ice systems exist—flake, cube, block, and plate—but Arctic-Temp® machines are built for one purpose: high-volume production of hard-cracked ice, the preferred choice for most industrial cooling applications.

Because Arctic-Temp® machines produce hard-cracked ice formed on vertical tube evaporators, they are ideal for:

Seafood processing

Meat and poultry facilities

Produce cooling

Bakeries and food processing operations

Industrial and agricultural applications

Large institutional needs (e.g., prisons)

Arctic-Temp® systems are available in two installation styles:

Skid-Mounted (SM-L) – self-contained units

Remote Condensing Units (AR-L / RCU) – evaporator and condenser installed separately

Key Factors to Consider When Choosing an Industrial Ice Maker

Before investing in a machine, evaluate the factors that determine long-term performance and reliability.

1. Daily Ice Production Requirements

Arctic-Temp® industrial ice makers produce between:

2,500 lbs/day

4,500 lbs/day

6,500 lbs/day

10,000 lbs/day

Calculate peak usage and include a 15–20% buffer for seasonal spikes, production surges, or maintenance cycles.

2. Installation Space & Ventilation

Ensure adequate space and airflow around your machine. Remote condensing units may be ideal for hot environments or facilities with tight indoor conditions.

3. Water Quality & Filtration

Proper filtration reduces scale buildup and improves machine longevity. Poor water quality directly reduces ice output.

4. Electrical Requirements

Check voltage, phase, and amperage needs to ensure compatibility with your facility’s power infrastructure.

5. Operating Climate

Arctic-Temp® machines are realistically rated and tested to perform in hot southern climates, ensuring reliable ice production even during high-heat conditions.

Maximizing Your Investment

Ice Storage Solutions

Pair your machine with an appropriate bin capacity to ensure a consistent supply during peak times.

Durability & Maintenance

Arctic-Temp® machines use:

Type-304 stainless steel

Copeland compressors

Double-walled vertical freezing tubes

This ensures longevity and straightforward maintenance.

Energy Efficiency

Arctic-Temp® units utilize recirculated water and efficient refrigeration cycles to reduce operating costs without sacrificing performance.

Level Up Your Business With Holiday Ice Inc.

Choosing the right industrial ice maker is easier when you have expert guidance. With 60+ years of engineering experience, Holiday Ice Inc. provides high-capacity, hard-cracked ice machines built for demanding industrial applications.

For additional buying guidance, don’t miss our companion resource:

How to Choose the Right Ice Machine for Your Business

To request a quote or get personalized recommendations, call (800) 362-3243 today.