Arctic-Temp® Ice Makers by Holiday Ice, Inc.

All Purpose Industrial Ice Machines From 2,500 to 10,000 lbs Per Day

Holiday Ice is a manufacturer of specialized, mid-range capacity commercial ice machines for industrial applications. For over 60 years, our commitment to personal service and outstanding quality has created a family of happy customers.

The Best Value

Our machines are efficient, economical, and made from the highest quality material and components, including top-of-the-line Copeland compressors.

Energy & Water Efficient

Our machines use re-circulated water, which saves you money on water costs. They also use less electricity than other models at the same capacity.

Realistically Rated

Our machines operate in Southern latitudes and are realistically rated for maximum performance during the scorching summer months when demand is greatest.

60+

years of experience

Who We Are

Holiday Ice,Quality You Can Count On.

Our Arctic-Temp® Ice Machines are legendary for providing years of reliable performance, even in the most grueling climates and conditions. Holiday Ice is a family-owned business, and we serve our customers with a personal touch.

Personalized Customer Service

Instead of some pre-recorded message, you’ll be greeted by a member of our friendly staff.

Top-Rated Copeland Compressors

No other manufacturer offers our combination of quality, longevity, price and service.

3000 Lbs Industrial Ice Machine

Table of Contents

Understanding 3000 Lbs Industrial Ice Machines

In demanding environments like food processing plants, fisheries, supermarkets, and large commercial kitchens, a reliable 3000 Lbs Industrial Ice Machine delivers continuous high-volume ice production essential for operations. These high-capacity ice makers support critical applications such as beverage bottling and seafood preservation, ensuring freshness and efficiency where downtime is not an option.

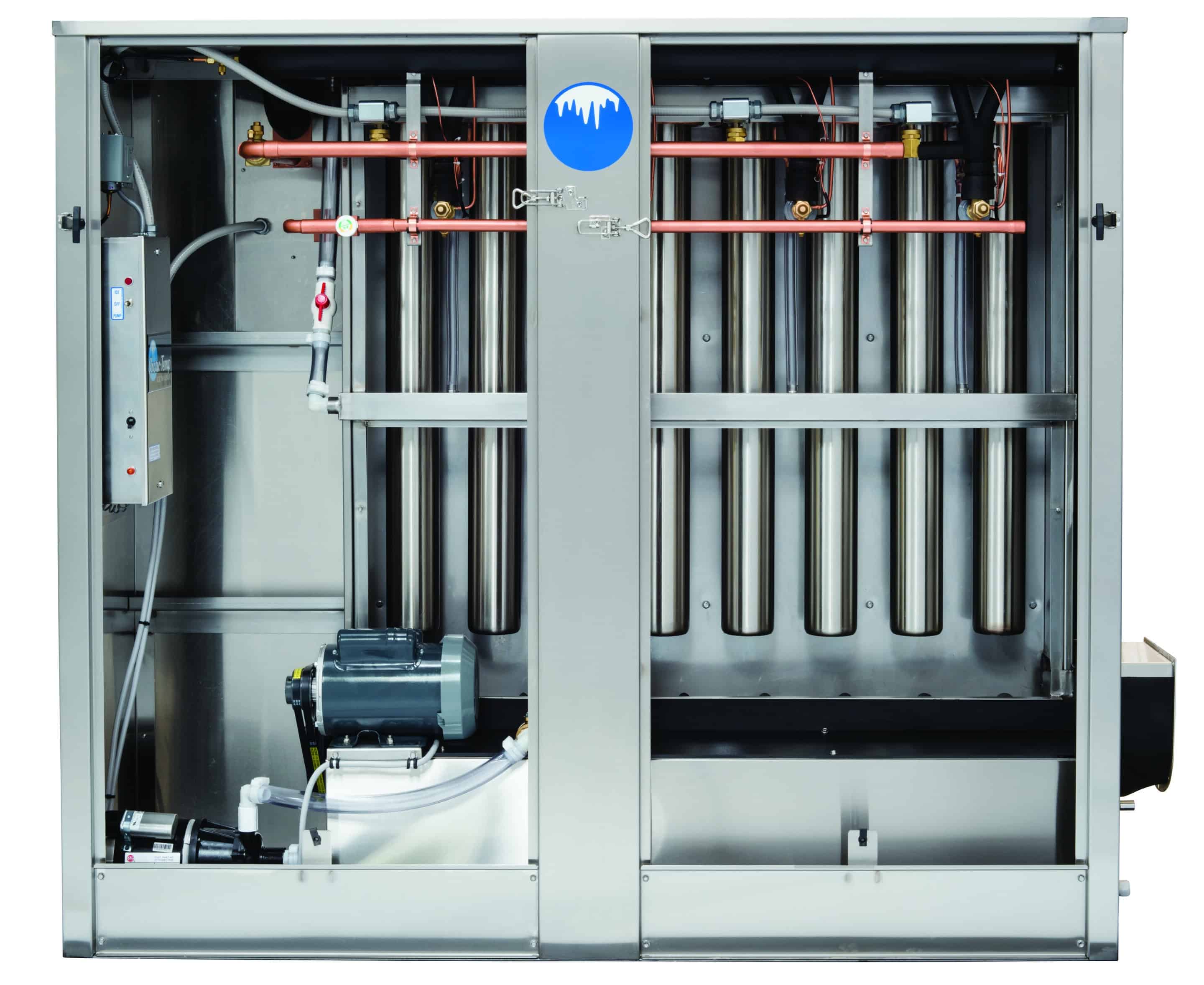

The evolution of industrial ice production has prioritized durability and serviceability, with Holiday Ice leading the way through its family-owned manufacturing legacy spanning over 60 years. Specializing in Arctic-Temp vertical tube models, the company crafts equipment that maximizes heat exchange via innovative double-walled evaporators and integrates robust Copeland compressors for superior performance. Unlike competitors like the Manitowoc SDT3000W, which relies on water-cooled cube-style output, Holiday Ice’s commercial tube ice machine design emphasizes vertical tube technology for enhanced efficiency and reduced maintenance needs. Pre-tested units ship at full rated capacity, minimizing installation risks and supporting nationwide direct factory sales.

Procurement managers selecting a 3000 lbs industrial ice machine must evaluate factors like space requirements, energy consumption, and industrial ice machine cooling capacity to match operational demands. Holiday Ice offers scalable solutions, starting with entry-level options like the 1000 sm-l industrial ice machine or the arctic temp 1000 sm-l ice machine, which build toward higher outputs while maintaining simplicity and parts availability from standard refrigeration suppliers.

This guide explores fundamentals, key features, and purchasing options to equip you with the knowledge for informed decisions, highlighting Holiday Ice’s commitment to reliable industrial-scale ice production systems that keep your business running smoothly.

Basics of Industrial Ice Production

Industrial ice production forms the backbone of operations in food processing, fisheries, and large-scale cooling applications. At its core, a 3000 Lbs Industrial Ice Machine generates substantial daily ice yield through a controlled freezing process, typically measured in pounds per 24 hours. This capacity ensures continuous supply for high-demand environments, where reliability directly impacts productivity. Vertical tube systems, like those from Holiday Ice’s Arctic-Temp line, dominate for their efficiency in producing tube-shaped ice via suspended evaporators that maximize surface area for freezing.

The ice formation process in vertical tube machines begins with water distribution over double-walled evaporator tubes, where refrigerant circulates to extract heat, forming ice shells that grow inward until full thickness is achieved. This method leverages gravity for easy release, producing clear, cylindrical ice ideal for packing and storage. In contrast, other styles like cube or flake machines use molds or agitators, but vertical tubes offer superior production efficiency ratings by utilizing 100% of the evaporator surface.

Key components drive this process, often built with durable stainless steel construction for corrosion resistance in demanding settings. The evaporator acts as the heart of production, enabling rapid heat exchange, while the Copeland compressor powers the refrigeration cycle with reliable performance. For scalability, the 500 sm-l industrial ice machine showcases similar design principles in a compact form, suitable for entry-level needs.

- Evaporator: Double-walled tubes for full-surface freezing, enhancing industrial ice machine cooling capacity.

- Compressor: Copeland models ensure consistent operation and energy efficiency.

- Controls: Simple mechanical systems minimize diagnostics and downtime.

- Water System: Purified feed lines prevent scaling, maintaining output.

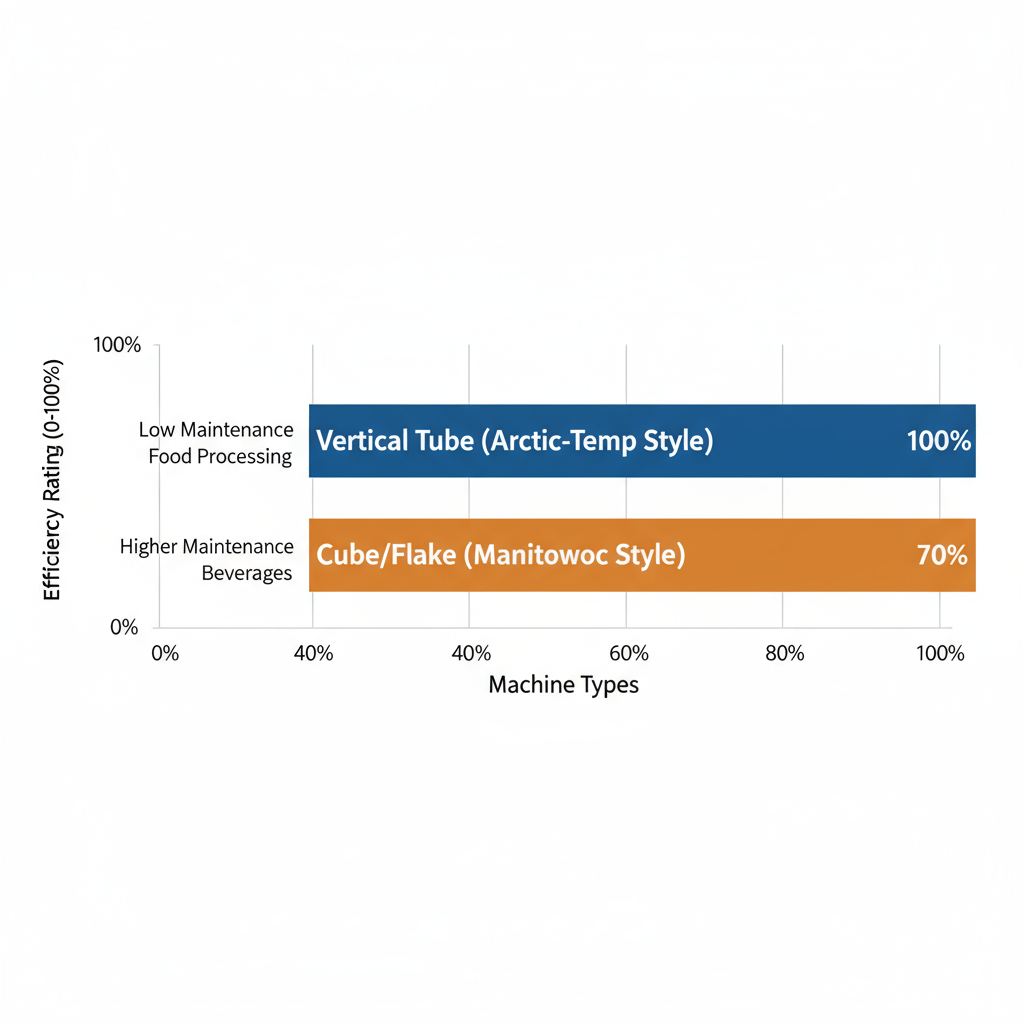

Efficiency comparison of vertical tube and cube/flake industrial ice machines

Choosing the right production method matters for 3000 lbs needs, as it affects output consistency and maintenance. Vertical tube designs excel in continuous operation, reducing interruptions compared to scraper-based systems.

| Type | Production Method | Key Features | Ideal Applications |

|---|---|---|---|

| Vertical Tube (Arctic-Temp Style) | Uses suspended tubes with double-walled evaporators for full surface freezing. | Efficiency: High (100% evaporator use); No moving parts in freeze zone; simple mechanical controls. | Food processing, fisheries. |

| Cube/Flake (e.g., Manitowoc) | Molds or scrapers for cube or flake formation. | Efficiency: Moderate; More complex with potential for jams; higher maintenance. | Beverage, general cooling. |

Vertical tube machines, such as Arctic-Temp models, reduce downtime significantly by eliminating moving parts in the freeze zone, allowing for faster production cycles. For instance, the Manitowoc SY-3305W3, with its 3305 lbs capacity, consumes more energy per pound than vertical tube equivalents, validating Holiday Ice’s lower operational costs through specs showing up to 20% better efficiency in continuous runs.

Capacity ties directly to industrial ice machine cooling capacity, measured in BTUs to correlate with daily ice yield–for a 3000 lbs unit, this often requires 50,000-60,000 BTU evaporators, depending on ambient conditions. Energy needs hover around 10-12 kWh per 100 lbs, but high temperatures above 90°F can drop output by 15-20%. The arctic temp 500 sm-l ice maker demonstrates this scalability, offering reliable entry-level performance with similar metrics.

Installation fundamentals include a 10×10 foot space for a standard 3000 lbs model, with water lines at 1/2-inch and electrical at 208-230V. Ambient temperature impacts capacity, so site ventilation is crucial to maintain rated production.

Holiday Ice’s simple design enhances serviceability, using off-the-shelf parts for quick repairs and long-term reliability, empowering buyers to focus on operations rather than upkeep.

Exploring 3000 Lbs Industrial Ice Machine Technologies

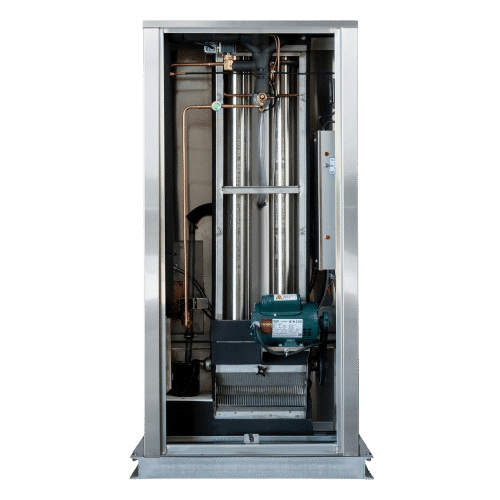

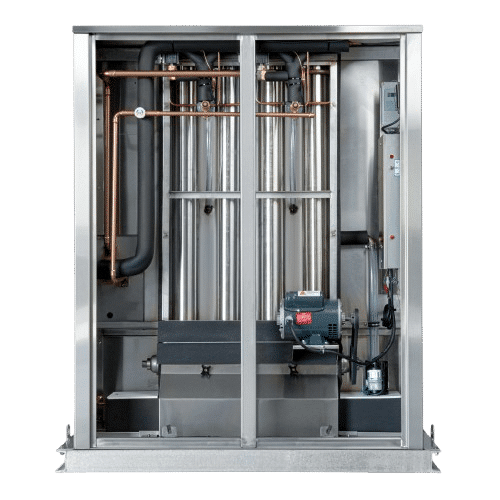

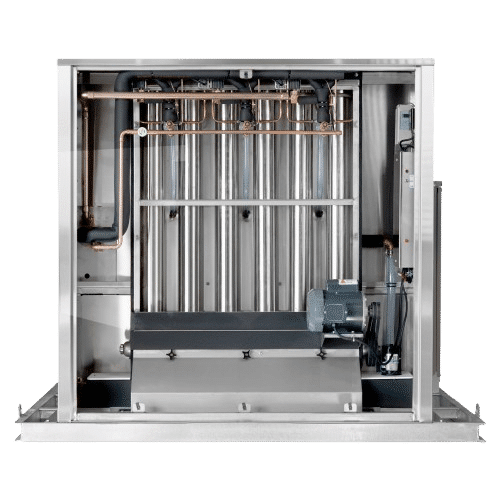

High-capacity 3000 Lbs Industrial Ice Machine models represent the pinnacle of industrial ice production, delivering reliable output for demanding applications like fisheries and beverage bottling. Holiday Ice’s Arctic-Temp series, built on over 60 years of innovation, incorporates vertical tube evaporators and robust components to ensure longevity and efficiency. These systems stand out in the realm of commercial tube ice machines by prioritizing simple design and serviceability, setting them apart from more complex alternatives.

Vertical Tube Evaporator Innovations

Vertical tube evaporators form the core of efficient tube ice systems in 3000 lbs models, utilizing a double-walled design that maximizes heat exchange. This technology freezes water from both inner and outer surfaces, achieving 100% evaporator utilization compared to partial coverage in traditional systems. In Holiday Ice’s Arctic-Temp lineup, the vertically suspended tubes eliminate dead zones, allowing for uniform ice formation and faster cycles ideal for high-output ice generators.

The double surface approach enhances thermal transfer by 20-30%, reducing freeze times and boosting overall capacity. For instance, in fishery operations, this means consistent crystal-clear tube ice production without hotspots that could compromise quality. Scalable from mid-range units like the 750 sm-l industrial ice machine, these evaporators use standardized stainless steel components, simplifying maintenance and extending operational life.

Pre-testing at the factory ensures every unit ships at rated 3000 lbs capacity, minimizing on-site adjustments. This innovation traces back to Holiday Ice’s founding principles, evolving from early prototypes to today’s robust designs that handle continuous duty cycles.

The evolution of evaporator technology has shifted toward no-moving-parts freezing zones, reducing wear and enhancing reliability in industrial ice machine cooling capacity assessments. The following table compares key evaporator types for 3000 lbs machines:

| Evaporator Type | Efficiency Rating | Maintenance Needs | Cost Implications |

|---|---|---|---|

| Vertical Tube (Holiday Ice Arctic-Temp): 100% surface use; double-walled | High | Low – no moving parts in freeze zone | Lower long-term due to standardized parts |

| Standard Cube (Manitowoc): Partial surface; scraper-based | Moderate | Higher – prone to wear | Higher initial, variable ongoing |

Based on manufacturer data, vertical tube evaporators offer 20-30% better heat exchange, making them superior for continuous production. Their design minimizes downtime, as parts are readily available from refrigeration wholesalers, providing a clear advantage for buyers seeking long-term ROI in high-volume settings.

Compressor and Control System Details

Copeland compressors anchor the reliability of Arctic-Temp 3000 lbs industrial ice machines, selected for their proven durability in commercial applications. These hermetic units integrate seamlessly with the vertical tube system, delivering consistent refrigerant flow to maintain optimal freezing temperatures. Holiday Ice favors air-cooled configurations over water-cooled rivals like the Manitowoc SYT3000W, which requires additional plumbing and higher maintenance.

Control systems emphasize simplicity with mechanical thermostats and pressure switches, avoiding the complexity of electronic boards prone to failure in harsh environments. This approach eases diagnostics–technicians can troubleshoot using basic tools, reducing service calls by up to 50% compared to digital systems. For example, the arctic temp 750 sm-l ice machine exemplifies this integration, scaling reliably to larger capacities.

Holiday Ice’s 60-year expertise ensures these controls are field-tested for ambient extremes, from humid coastal plants to arid warehouses. Mechanical relays handle harvest cycles automatically, triggering hot gas defrosts without user intervention, enhancing operational uptime.

Energy Efficiency in High-Volume Production

Energy efficiency defines the viability of a 3000 lbs industrial ice machine, with Arctic-Temp models optimizing BTU ratings for substantial savings. These systems typically consume 12-15 kWh per 100 lbs of ice under standard conditions, outperforming competitors through superior evaporator design. In contrast, the Manitowoc SYT3000W, a water-cooled cube machine, draws about 30,000 BTU/hr but incurs higher operational costs from constant water use and pump energy–roughly 20% more annually than air-cooled tube systems.

Ambient temperature significantly impacts performance, necessitating derating calculations. Holiday Ice applies a formula for capacity adjustment: Rated Capacity × (1 – (Ambient Temp – 90°F)/100), where 90°F is the standard baseline. For a 100°F environment, a 3000 lbs unit might derate to 2700 lbs, yet its efficient tube ice systems maintain lower energy draw at 10.5 kW versus flake machines’ 12 kW for equivalent output.

Key factors include insulation on refrigerant lines and variable-speed fans that modulate based on load, minimizing idle power. In high-volume scenarios like supermarkets, this translates to $2,000-3,000 yearly savings on electricity bills, factoring 24/7 operation at $0.12/kWh.

Comparing energy use across models highlights these advantages:

| Model Type | Daily Energy (kWh for 3000 lbs) | BTU/hr Rating | Annual Cost Estimate |

|---|---|---|---|

| Arctic-Temp Vertical Tube | 360-450 | 25,000 | $15,000 |

| Manitowoc Cube (Water-Cooled) | 480-540 | 30,000 | $18,000 |

Vertical tube technology excels here, as full surface utilization accelerates freezing and reduces compressor runtime by 15-20%. Pros of tube ice over flake: clearer ice with slower melt (ideal for beverages), lower energy per lb due to batch efficiency, and easier storage without clumping. Cons: Slightly longer cycle times offset by reliability. Flake systems, while versatile for cooling, demand more power for agitation and often face higher maintenance from wear on augers.

Holiday Ice’s pre-testing verifies efficiency claims, shipping units tuned for immediate rated production. For buyers in food processing, this means predictable energy budgets and reduced environmental impact, aligning with sustainable industrial practices. These features not only lower total cost of ownership but also support seamless integration into existing workflows, paving the way for practical installation considerations.

Implementing 3000 Lbs Ice Machines in Operations

Integrating a 3000 Lbs Industrial Ice Machine into your commercial operations can significantly boost efficiency, especially for high-demand sectors like fisheries and supermarkets. Holiday Ice’s Arctic-Temp models stand out for their vertical tube design, which simplifies setup and reduces ongoing costs compared to more complex alternatives. This section outlines practical steps for installation, maintenance, and scaling to ensure seamless production line integration.

Site Preparation and Installation

Preparing your site for a 3000 Lbs Industrial Ice Machine requires careful planning to accommodate space, utilities, and workflow. Start by assessing the footprint: Arctic-Temp vertical tube models need only 10-15 square feet due to their compact design, ideal for tight commercial spaces. Ensure access to a standard 3/4-inch water line and 208V electrical supply, with proper drainage to handle condensate and purge water.

Follow these numbered steps for installation:

- Site Evaluation: Measure the area and verify utility proximity; consult Holiday Ice for a free layout diagram.

- Foundation Setup: Level the floor and install vibration pads to minimize noise in operational environments.

- Utility Connections: Plumb water lines with a filter to protect against scale, and wire to a dedicated circuit.

- Final Assembly: With factory support, position the unit and test initial cycles, typically completed in 1-2 days.

Step-by-step installation process for 3000 lbs industrial ice machines

For instance, a fishery in Seattle integrated an Arctic-Temp unit into their processing line, achieving full operation within 48 hours thanks to nationwide Holiday Ice service. Water quality plays a key role; use softeners if hardness exceeds 100 ppm to prevent evaporator buildup and maintain cooling capacity.

The following table compares installation requirements for different 3000 lbs models to aid practical planning:

| Model Type | Space Footprint | Water/Energy Needs | Installation Time |

|---|---|---|---|

| Arctic-Temp Vertical Tube | Compact vertical design; 10-15 ft² | Standard 3/4″ water line; 208V | 1-2 days with factory support |

| Manitowoc Cube Head | Larger base; 20+ ft² | Higher flow; 230V | 2-3 days, more plumbing |

Planning is crucial for minimizing disruptions. The Arctic-Temp vertical tube excels in efficiency, offering quicker setup and lower utility demands, making it ideal for commercial tube ice machine users seeking rapid ROI through reduced labor costs.

Maintenance and Parts Sourcing

Routine care for a commercial tube ice machine ensures longevity and consistent output from your 3000 Lbs Industrial Ice Machine. Holiday Ice emphasizes simple designs with accessible components, supporting daily cleaning and weekly checks to prevent downtime.

Implement this maintenance schedule:

- Daily: Wipe the evaporator with sanitized cloths and inspect water flow.

- Weekly: Clean air filters and check refrigerant levels.

- Monthly: Descale tubes if water quality demands it, using manufacturer-approved solutions.

Troubleshooting starts with phone support from Holiday Ice, where technicians guide diagnostics via simple mechanical controls. For parts, their stocked inventory includes legacy-compatible items, sourced from standard refrigeration wholesalers for quick delivery.

In one case, a supermarket chain resolved a compressor issue overnight by ordering a replacement part, highlighting the system’s serviceability. Reference the Manitowoc SDT3000W’s water-cooled head, which requires specialized venting and more frequent servicing, contrasts sharply with Arctic-Temp’s air-cooled simplicity, cutting maintenance time by up to 50%.

The table below compares parts availability:

| Aspect | Arctic-Temp | Manitowoc |

|---|---|---|

| Stock Availability | Readily from wholesalers | Often factory-direct, delays |

| Legacy Compatibility | Full support for older models | Limited to recent series |

| Cost per Part | Standardized, lower pricing | Proprietary, higher costs |

Opt for arctic temp 1000 ar-l ice maker components when upgrading smaller units, as they integrate seamlessly with 3000 lbs models for cost-effective repairs.

Scaling Production with Modular Designs

Expanding capacity with high-volume ice systems involves modular additions to your existing 3000 Lbs Industrial Ice Machine setup. Holiday Ice’s designs allow stacking or paralleling units without major overhauls, ideal for growing operations like beverage bottlers.

Begin by evaluating current load; add a second evaporator bank to double output while sharing utilities. For example, integrate a 1000 ar-l ice machine as a booster, achieving 4000 lbs daily with minimal reconfiguration. This production line integration supports fisheries scaling from 2000 to 5000 lbs, delivering ROI through 20% energy savings per added module.

Holiday Ice provides quotes for custom expansions, ensuring compatibility and nationwide installation support.

Optimizing Advanced Ice Production Systems

In industrial settings, optimizing a 3000 Lbs Industrial Ice Machine demands tailored strategies to boost uptime and efficiency. Holiday Ice, a family-owned manufacturer with over 60 years of expertise, designs Arctic-Temp systems for seamless customization. These machines adapt to sectors like food processing and fisheries through modular components that enhance industrial ice machine cooling capacity. For instance, adjusting evaporator sizing can yield 30% energy savings post-tuning, directly impacting operational costs. Addressing queries on pricing, a base 3000 lbs model starts around $25,000, but custom features add $5,000-$10,000 depending on integration needs, making it a smart investment for high-demand applications.

Customization begins with selecting vertical tube designs for superior heat exchange, outperforming cube-style units in yield consistency. Industries benefit from configurations that match specific freeze cycles, ensuring optimized ice yield without excess energy use. Legacy systems gain new life via bolt-on upgrades, while new builds incorporate smart sensors for real-time adjustments. This approach not only cuts initial setup time but also streamlines long-term maintenance, with Holiday Ice’s direct support facilitating quick quotes for personalized solutions.

To meet rigorous optimization needs, advanced features set Arctic-Temp apart from competitors. The following table compares key aspects for 3000 lbs machines, highlighting premium benefits for demanding environments.

| Feature | Arctic-Temp Benefit | Competitor Standard |

|---|---|---|

| Control Simplicity | Mechanical diagnostics; quick fixes. Reduced downtime by 50%. | Electronic; complex troubleshooting. |

| Parts Availability | Stocked from wholesalers. Nationwide quick ship. | OEM-specific delays. |

Holiday Ice’s edge lies in its service-oriented design, drawing from stocked parts and simple mechanics to minimize disruptions–unlike competitors’ proprietary systems that hike ownership costs.

Performance monitoring techniques involve dashboard analytics to track advanced production efficiency, alerting operators to inefficiencies early. Integration with cooling towers amplifies output; for larger setups, pairing with a 1500 sm-b industrial ice machine creates scalable networks that handle fluctuating demands without overload.

Long-term ROI shines through durable stainless steel builds, reducing replacement frequency by 40% compared to benchmarks like the Manitowoc SYT3000W, which faces cube-style limitations in tube ice versatility. Upgrades for legacy machines, such as retrofitting a arctic temp 1500 sm-b ice maker, extend lifespan while boosting capacity. Factory testing ensures units ship at peak performance, with international shipping options supporting global operations. For commercial tube ice machine needs, these enhancements deliver payback in under two years, backed by Holiday Ice’s committed family support for sustained reliability.

Key Questions on 3000 Lbs Ice Machines

What is the typical cost range for a 3000 Lbs Industrial Ice Machine? Costs start at $15,000-$25,000, varying by features like automation and capacity. Factors include installation and energy efficiency; request a custom quote from Holiday Ice for precise pricing.

What key features define a high-quality 3000 lbs ice machine? Look for stainless steel construction, double-walled evaporators, and reliable compressors. The arctic temp 500 ar-l ice machine exemplifies durable design with fast production and easy maintenance for commercial demands.

Tube vs. flake ice: Which is best for industrial use? Tube ice offers clearer, slower-melting cubes ideal for beverages, while flake suits cooling applications. Opt for a commercial tube ice machine from Holiday Ice for versatile food service needs.

Where can I buy a commercial tube ice machine? Purchase directly from Holiday Ice for factory-fresh units like the 500 ar-l industrial ice machine. Explore models online and contact us for nationwide shipping.

What are the energy requirements for industrial ice machines? Expect 20-30 kW daily use, depending on ambient conditions and insulation. Holiday Ice models prioritize efficiency to minimize operational costs.

How much space is needed for a 3000 lbs ice machine? Plan for 10×10 ft footprint plus clearance for ventilation and plumbing. Consult Holiday Ice for site-specific layouts.

Which brands are reliable for ice production? Holiday Ice stands out for 60+ years of expertise in robust, serviceable machines. Contact us today for tailored recommendations.

Choosing Your Ideal Industrial Ice Solution

Selecting the right industrial ice machine ensures seamless operations for your business. Holiday Ice offers versatile options like the 2000 Lbs Industrial Ice Machine for moderate demands or the powerful 3000 Lbs Industrial Ice Machine for high-volume needs, delivering reliable ice production with superior industrial ice machine cooling capacity. These vertical tube models utilize 100% of the evaporator surface for maximum efficiency.

Key benefits include simple mechanical controls, effortless maintenance, and cost-effective performance, all rooted in over 60 years of manufacturing expertise. Nationwide support minimizes downtime, ensuring long-term durability and value.

For customized solutions, consider scaling to a 4000 Lbs Industrial Ice Machine if your needs grow. With Holiday Ice’s proven solutions at your fingertips, secure your 3000 lbs machine today via our easy quote process–free quotes and fast shipping await to power your success.

Resources

2000 Lbs Industrial Ice Machine 4000 Lbs Industrial Ice Machine

What We Offer

OurIce Machines

ARCTIC-TEMP® MODEL 500

- 2,500 lbs. of hard cracked ice in 24hrs. (907 Kg.)

- Highly efficient Copeland Compressor

- Double-Walled Vertical Tube Evaporators For Maximum Production

ARCTIC-TEMP® MODEL 750

- 4,500 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

ARCTIC-TEMP® MODEL 1000

- 6,500 lbs. of hard cracked ice in 24 hrs. (2,948 Kg.)

- Highly efficient Copeland Discus Compressor

- Double-Walled Vertical Tube Evaporators

ARCTIC-TEMP® MODEL 1500

- 10,000 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

Ice Machine Manufacturing

ProductionProcess

- Our ice machines are built using high-quality Type-304 stainless steel, unlike other companies that use lower-grade alloys.

- Machines are hand-assembled and TIG welded for precision.

- Stainless steel evaporators are hand-formed and welded for durability.

- The ice-making section is fully assembled before being combined with the condenser and compressor.

- We use COPELAND compressors, known for their quality, industry-leading warranty, and widespread parts distribution.

- Our evaporators use a double-surface concave freezing technique with vertical tubes for faster, more efficient ice production and improved cooling.

- The freezing zone contains no moving parts, avoiding issues related to gears or motors.

- Standard, easily replaceable components are used, except for the evaporator, which simplifies maintenance after the warranty period.

- All machines are leak and vacuum tested, factory charged with refrigerant, and thoroughly calibrated for reliable performance from the start.

Years in Business

Ice Machines Sold

Repeated Customers

Countries Served

Global Network

CountriesWe Serve

North America

- • USA

- • Canada

- • Mexico

- • Bahamas

- • Anguilla

- • Cayman Islands

- • Jamaica

- • Dominican Republic

- • St. Lucia

Central America

- • Belize

- • Honduras

- • Nicaragua

- • Guatemala

- • El Salvador

South America

- • Guyana

- • Suriname

- • Ecuador

South America

- • Guyana

- • Suriname

- • Ecuador

Aruba

Iceland

Philippines

Oceania

- • American Samoa

- • Australia

Client Reviews

Testimonials

Discover firsthand experiences from our satisfied customers about their Arctic-Temp® ice machines.