Arctic-Temp® Ice Makers by Holiday Ice, Inc.

All Purpose Industrial Ice Machines From 2,500 to 10,000 lbs Per Day

Holiday Ice is a manufacturer of specialized, mid-range capacity commercial ice machines for industrial applications. For over 60 years, our commitment to personal service and outstanding quality has created a family of happy customers.

The Best Value

Our machines are efficient, economical, and made from the highest quality material and components, including top-of-the-line Copeland compressors.

Energy & Water Efficient

Our machines use re-circulated water, which saves you money on water costs. They also use less electricity than other models at the same capacity.

Realistically Rated

Our machines operate in Southern latitudes and are realistically rated for maximum performance during the scorching summer months when demand is greatest.

60+

years of experience

Who We Are

Holiday Ice,Quality You Can Count On.

Our Arctic-Temp® Ice Machines are legendary for providing years of reliable performance, even in the most grueling climates and conditions. Holiday Ice is a family-owned business, and we serve our customers with a personal touch.

Personalized Customer Service

Instead of some pre-recorded message, you’ll be greeted by a member of our friendly staff.

Top-Rated Copeland Compressors

No other manufacturer offers our combination of quality, longevity, price and service.

Large Scale Ice Production

The Importance of Quality Materials in Ice Production

As part of our commitment to quality, we also utilize top-of-the-line Copeland compressors. These components not only contribute to the reliability of our systems but also enhance energy efficiency. By employing such quality materials, we guarantee that our clients can focus on their core operations without worrying about their ice production equipment.

Crafting a Large Scale Ice Production Strategy

Next, consider the spatial and environmental factors. Our machines are designed to operate efficiently even in Southern climates where temperatures soar and demand peaks. This ensures reliable performance year-round, a significant advantage for businesses that deal with seasonal fluctuations.

Finally, regular maintenance is essential. Our machines are built for easy servicing, with hand-assembled and TIG welded components for precision and strength. This attention to detail not only reduces downtime but also extends the lifespan of the equipment. By focusing on these key areas, businesses can optimize their ice production capabilities.

What Makes Clear Ice Essential?

In our experience, creating crystal-clear ice involves a process known as directional freezing. This technique forces impurities to settle away from the ice, resulting in a pristine product. By adopting such practices, our clients, ranging from upscale bars to industrial beverage producers, are able to elevate their offerings with each glass served.

Tackling Demand in Large Scale Ice Production

Moreover, our re-circulated water system saves on operating costs, offering both economic and environmental benefits. This innovative approach reduces water waste and electricity usage, aligning with modern sustainability goals. By choosing Holiday Ice, businesses not only achieve efficiency but also align with responsible environmental practices.

Common Questions About Large Scale Ice Production

A large scale ice production emergency typically arises when a critical component fails, halting operations. Quick resolution is essential to prevent supply shortages for dependent businesses such as restaurants or event venues. Our comprehensive support network ensures immediate assistance to minimize downtime.

- Insufficient ice supply during peak demand.

- System malfunctions causing full production stop.

- Environmental factors affecting ice quality.

At Holiday Ice, we pride ourselves on providing robust customer support to quickly address and resolve these issues, keeping our clients confidently operational.

The Innovations Behind Bulk Ice Makers

In my two decades of crafting commercial ice machines, I’ve witnessed an array of technological advancements. Bulk Ice Makers today integrate energy-efficient technologies that far surpass the capabilities of earlier models. Utilizing components like Copeland compressors, these machines are not just efficient; they are also durable and tailor-made for high-demand scenarios.

Our Arctic-Temp® Ice Machines at Holiday Ice ingeniously use recirculated water systems to minimize wastage while maximizing productivity. Innovations such as these are essential for maintaining performance, especially in the hotter southern climates where demand peaks during scorching summers.

Meeting Industrial Needs with Bulk Ice Makers

Industrial sectors require machines that can produce massive quantities of ice daily. Our range at Holiday Ice, with capacities from 2,500 to over 10,000 pounds per day, answers that call. What sets our Bulk Ice Makers apart is their ability to perform under intense conditions while remaining cost-effective over the long haul.

When ice is more than just a commodity–when it becomes a crucial component of your operational workflow–you can’t afford a machine that underdelivers. That’s why at Holiday Ice, each unit is hand-assembled and TIG welded for maximum durability, ensuring they meet the rigors of industrial application without compromising on quality.

What Qualifies as a Bulk Ice Makers Emergency?

Immediate attention is needed when a machine fails unexpectedly, threatening operations. Quick diagnostics and rapid replacement parts are crucial, particularly when demand is high.

1. Assess the issue using built-in diagnostics.

2. Contact your service provider immediately.

3. Keep a stock of essential replacement parts.

4. Schedule regular maintenance to prevent emergencies.

How to Choose the Best Bulk Ice Maker for Your Needs

Choosing the right Bulk Ice Makers involves understanding your unique needs and the environmental conditions they’ll operate in. Here are some steps to guide your decision:

- Evaluate your daily ice production requirements.

- Consider the environmental conditions–particularly temperature and humidity.

- Research models with energy-efficient features.

- Ensure easy access to replacement parts and service.

- Consult with experts for personalized recommendations.

By following these guidelines, you’ll optimize both performance and longevity, ensuring your operations run smoothly.

Client Testimonials and Insights

Through direct feedback from operators across North and South America, including places as diverse as Iceland and Australia, I’ve seen firsthand the importance of reliable Bulk Ice Makers. Our clients often highlight not just the machines’ efficiency but also the support they receive from our team at Holiday Ice. This combination of product quality and personal service forms the backbone of our enduring customer relationships.

- Reliable operation, even in extreme climates

- Top-notch customer service and support

- Durable construction for long-term use

These insights are not just anecdotes; they cement our reputation and provide a roadmap for future innovations as we aim to meet and exceed industry standards.

The Importance of Bulk Ice Makers in Industrial Applications

As someone with over two decades of experience at Holiday Ice, Inc., I’ve witnessed firsthand the pivotal role that Bulk Ice Makers play in industrial settings. These machines are indispensable for sectors like food processing, medical facilities, and large event venues. Bulk Ice Makers ensure that high-volume ice production needs are met efficiently, particularly during peak demand periods.

At Holiday Ice, our Arctic-Temp® Ice Machines are designed to handle the rigorous demands of industries across varied climates. By leveraging Copeland compressors and re-circulated water systems, our machines offer reliability and economy, making them a trusted choice worldwide.

How to Choose the Right Bulk Ice Maker

Selecting an appropriate Bulk Ice Maker involves several crucial considerations:

- Capacity Needs: Evaluate your daily ice requirements. Our models range from 2,500 to over 10,000 lbs per day, catering to diverse industrial needs.

- Energy Efficiency: Opt for models that optimize water and electricity usage, which can dramatically reduce operational costs.

- Durability and Material: Machines built with high-quality Type-304 stainless steel offer long-lasting resilience and performance.

- Regional Climate: Ensure that the machine is rated for optimal performance in your specific climatic conditions.

Effective Maintenance of Bulk Ice Makers

Maintaining a Bulk Ice Maker is crucial to prolonging its lifespan and ensuring optimal efficiency. Regular cleaning, especially of evaporators and filters, is essential to prevent mineral buildup and ensure sanitary ice production. At Holiday Ice, we emphasize using high-grade materials and components that make maintenance straightforward.

- Schedule routine inspections to check for wear and tear.

- Use recommended cleaning agents to maintain hygiene standards.

- Consult the user guide for specific maintenance schedules.

What Qualifies as a Bulk Ice Maker Emergency?

A Bulk Ice Maker emergency typically involves complete failure of ice production, leaks affecting operation, or equipment malfunction leading to potential downtime of critical operations. Addressing these issues promptly can prevent operational delays.

In my experience, swift resolution of these emergencies often requires having spare parts on hand and access to reliable customer support. At Holiday Ice, our friendly staff is always on standby to ensure minimal disruption in your operations.

Why Investing in a Bulk Ice Maker is a Smart Decision

Investing in a Bulk Ice Maker is not just about securing an ice supply; it’s about future-proofing your operations. I’ve seen how our clients benefit from reliable, high-capacity ice production, which can directly influence operational efficiency and customer satisfaction. By choosing a trusted manufacturer like Holiday Ice, you’re investing in a legacy of quality and performance. Our machines don’t just produce ice; they deliver peace of mind–day after day, year after year.

Whether you’re operating in the bustling markets of North America or the diverse climates of Australia, a Bulk Ice Maker from Holiday Ice ensures you’re equipped to meet any challenge head-on.

What are the benefits of using high-quality materials in ice production machines?

At Holiday Ice, we believe that using high-quality materials in our ice production machines offers several key benefits. Our choice of Type-304 stainless steel ensures exceptional durability and resistance to corrosion, which is crucial in demanding environments. This means our Arctic-Temp® ice machines perform reliably over years, minimizing the need for frequent repairs or replacements. Additionally, by using top-tier Copeland compressors, we enhance energy efficiency while maintaining consistent performance. These decisions reflect our commitment to providing reliable solutions that our clients can depend on, allowing them to focus on their core business operations without worrying about the machinery supporting them.

Why is clear ice considered essential in beverage service?

Clear ice is often seen as a mark of quality in beverage service because it not only looks aesthetically appealing but also indicates purity. Clear ice melts more slowly and maintains its shape longer, which helps preserve the flavor and chill of the drink without watering it down too quickly. This is especially important in high-end bars and restaurants where presentation and taste are equally important. The process to achieve this clarity, known as directional freezing, helps remove impurities, resulting in a pristine product that enhances the overall drinking experience. It’s a small detail that can make a big difference in customer satisfaction.

How should businesses plan for large-scale ice production effectively?

Effective planning for large-scale ice production starts with accurately assessing your daily ice requirements. This involves understanding peak demand periods so that you can choose machines with the appropriate capacity. At Holiday Ice, our machines range from 2,500 to over 10,000 lbs per day, providing flexibility for various business needs. It’s also crucial to consider spatial and environmental factors, such as the machine’s ability to operate efficiently in high-temperature settings. Regular maintenance is key to keeping production smooth, which is why our machines are designed for easy servicing. These strategies help businesses optimize their production capabilities and reduce downtime.

How can large-scale ice producers handle fluctuations in demand?

Handling fluctuating demand in large-scale ice production requires a combination of reliable equipment and strategic planning. Our Arctic-Temp® machines are built to handle peak demands, especially in hotter climates where ice is in higher demand. Moreover, integrating energy-efficient and resource-saving technologies, like our re-circulated water system, helps manage operating costs more effectively. By using machines that are rated for maximum performance in challenging conditions, companies can meet market demands consistently. Alignment with environmental goals through technology also future-proofs operations by reducing energy and water footprints, offering both economic and ecological benefits.

What constitutes a large-scale ice production emergency and how can it be managed?

A large-scale ice production emergency usually involves sudden equipment failure that halts production, causing potential supply shortages. Addressing this type of emergency promptly is critical. At Holiday Ice, we emphasize the importance of having a support network that offers immediate assistance. Regular maintenance and having replacement parts on hand can mitigate risks. Quick diagnostics, facilitated by built-in machine features, allow for rapid response and minimize downtime. Proper planning for these contingencies ensures that businesses remain operational even when unexpected issues arise.

What factors should be considered when choosing a bulk ice maker?

Selecting the right bulk ice maker involves several key considerations. First, determine your daily ice production needs to ensure the machine can meet your demand. Assess the environmental conditions of your location, as machines need to perform efficiently even in high-temperature and humid areas. Exploring models with energy-efficient features can lead to significant savings in utility costs. Also, consider the availability of replacement parts and service options to ensure maintenance is straightforward. Getting expert advice tailored to your specific needs can provide valuable insights into making the best choice for your business.

What are the best practices for maintaining a bulk ice maker?

Effective maintenance of a bulk ice maker is crucial for its longevity and efficiency. Regularly cleaning components such as evaporators and filters is essential to prevent mineral buildup and ensure sanitary ice production. At Holiday Ice, we recommend following a maintenance schedule outlined in our user guide and using recommended cleaning agents. Routine inspections to check for wear and tear are vital, as is having spare parts readily available. By prioritizing maintenance, businesses can avoid unexpected breakdowns and extend the lifespan of their equipment. This proactive approach helps ensure continuous, reliable ice production.

Why should businesses invest in a bulk ice maker?

Investing in a bulk ice maker is a strategic decision for any business that relies heavily on ice production. It ensures a consistent supply, directly influencing operational efficiency and customer satisfaction. At Holiday Ice, we provide machines with proven reliability and efficiency, thanks to our innovative designs and use of quality materials. Our clients benefit from peace of mind, knowing their operations can meet demand without disruption. Whether you’re serving bustling markets in North America or facing diverse climatic conditions elsewhere, having a reliable ice maker is key to maintaining business continuity and success.

Resources

- Centers for Disease Control and Prevention – Official website providing valuable information on health and safety, including guidelines for industrial settings.

- U.S. Department of Energy – Resource for energy efficiency technologies and best practices that can be applied to industrial ice production.

- U.S. Food and Drug Administration – Regulatory authority overseeing food safety, including standards for ice production in food processing industries.

- National Institute of Standards and Technology – Leading research organization providing scientific and technological resources relevant to ice production innovations.

- U.S. Department of Agriculture – Information on agricultural practices and standards that may impact the production of ice for industrial use.

What We Offer

OurIce Machines

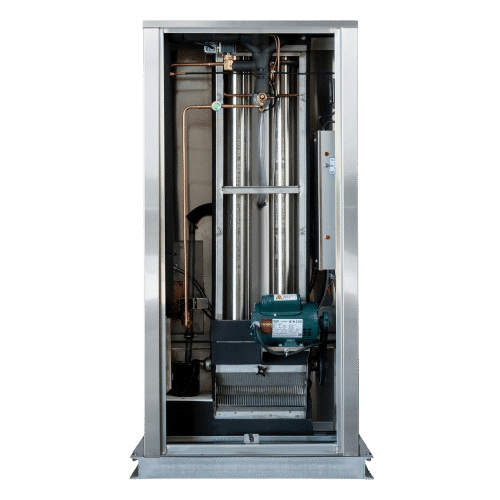

ARCTIC-TEMP® MODEL 500

- 2,500 lbs. of hard cracked ice in 24hrs. (907 Kg.)

- Highly efficient Copeland Compressor

- Double-Walled Vertical Tube Evaporators For Maximum Production

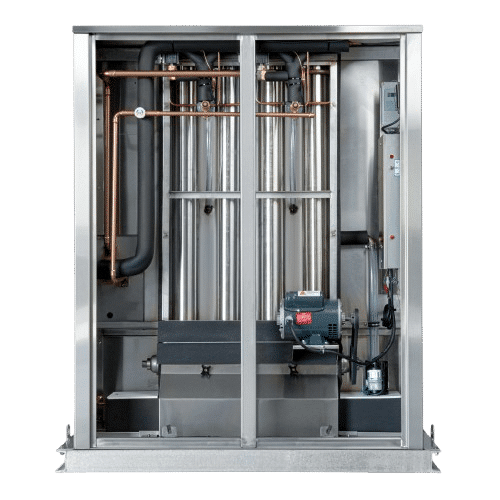

ARCTIC-TEMP® MODEL 750

- 4,500 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

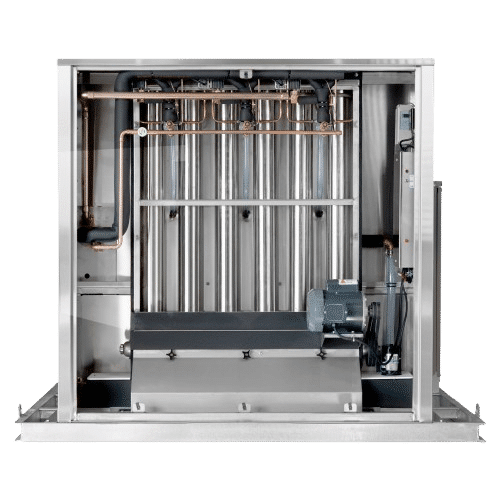

ARCTIC-TEMP® MODEL 1000

- 6,500 lbs. of hard cracked ice in 24 hrs. (2,948 Kg.)

- Highly efficient Copeland Discus Compressor

- Double-Walled Vertical Tube Evaporators

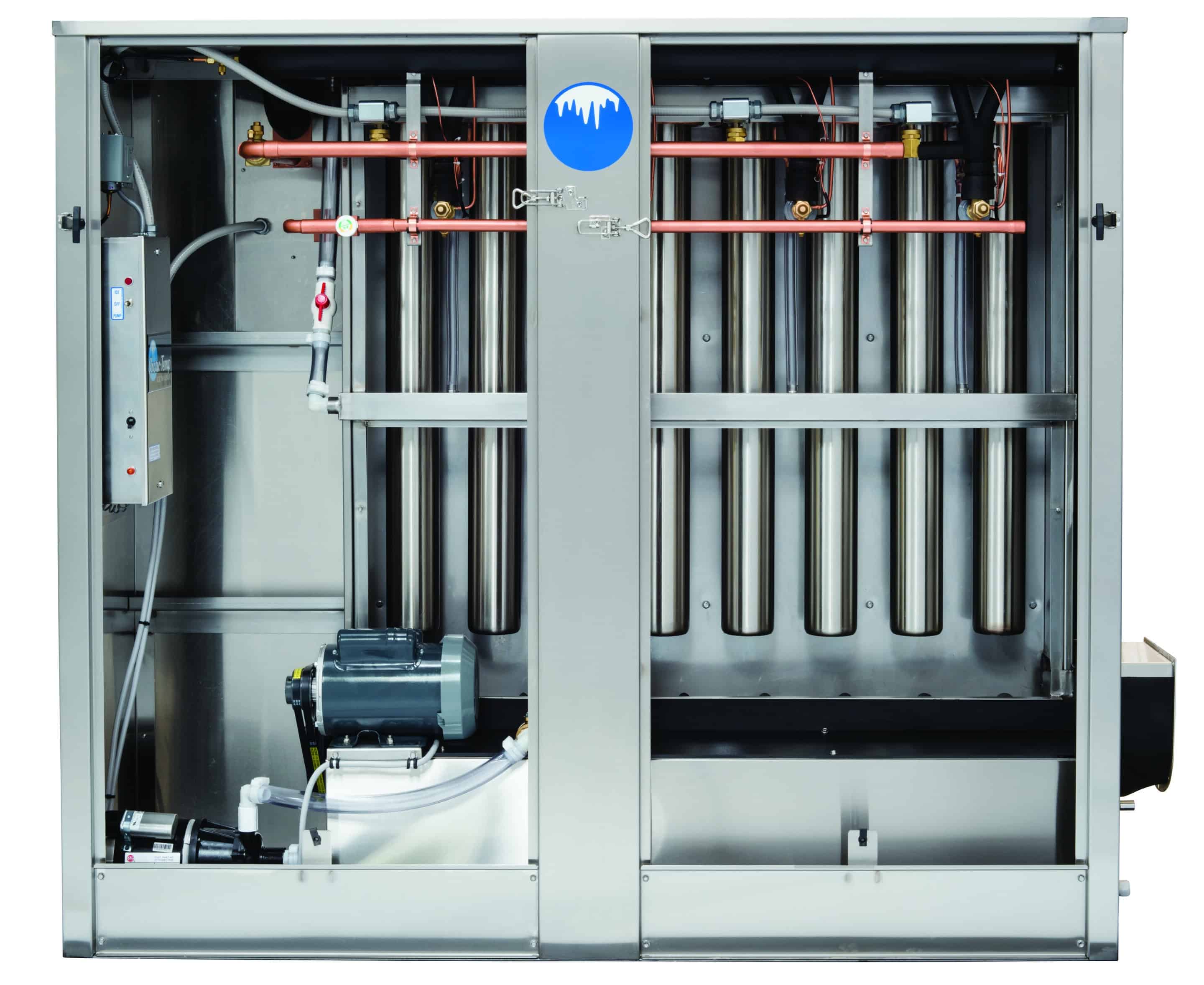

ARCTIC-TEMP® MODEL 1500

- 10,000 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

Ice Machine Manufacturing

ProductionProcess

- Our ice machines are built using high-quality Type-304 stainless steel, unlike other companies that use lower-grade alloys.

- Machines are hand-assembled and TIG welded for precision.

- Stainless steel evaporators are hand-formed and welded for durability.

- The ice-making section is fully assembled before being combined with the condenser and compressor.

- We use COPELAND compressors, known for their quality, industry-leading warranty, and widespread parts distribution.

- Our evaporators use a double-surface concave freezing technique with vertical tubes for faster, more efficient ice production and improved cooling.

- The freezing zone contains no moving parts, avoiding issues related to gears or motors.

- Standard, easily replaceable components are used, except for the evaporator, which simplifies maintenance after the warranty period.

- All machines are leak and vacuum tested, factory charged with refrigerant, and thoroughly calibrated for reliable performance from the start.

Years in Business

Ice Machines Sold

Repeated Customers

Countries Served

Global Network

CountriesWe Serve

North America

- • USA

- • Canada

- • Mexico

- • Bahamas

- • Anguilla

- • Cayman Islands

- • Jamaica

- • Dominican Republic

- • St. Lucia

Central America

- • Belize

- • Honduras

- • Nicaragua

- • Guatemala

- • El Salvador

South America

- • Guyana

- • Suriname

- • Ecuador

South America

- • Guyana

- • Suriname

- • Ecuador

Aruba

Iceland

Philippines

Oceania

- • American Samoa

- • Australia

Client Reviews

Testimonials

Discover firsthand experiences from our satisfied customers about their Arctic-Temp® ice machines.