Arctic-Temp® Ice Makers by Holiday Ice, Inc.

All Purpose Industrial Ice Machines From 2,500 to 10,000 lbs Per Day

Holiday Ice is a manufacturer of specialized, mid-range capacity commercial ice machines for industrial applications. For over 60 years, our commitment to personal service and outstanding quality has created a family of happy customers.

The Best Value

Our machines are efficient, economical, and made from the highest quality material and components, including top-of-the-line Copeland compressors.

Energy & Water Efficient

Our machines use re-circulated water, which saves you money on water costs. They also use less electricity than other models at the same capacity.

Realistically Rated

Our machines operate in Southern latitudes and are realistically rated for maximum performance during the scorching summer months when demand is greatest.

60+

years of experience

Who We Are

Holiday Ice,Quality You Can Count On.

Our Arctic-Temp® Ice Machines are legendary for providing years of reliable performance, even in the most grueling climates and conditions. Holiday Ice is a family-owned business, and we serve our customers with a personal touch.

Personalized Customer Service

Instead of some pre-recorded message, you’ll be greeted by a member of our friendly staff.

Top-Rated Copeland Compressors

No other manufacturer offers our combination of quality, longevity, price and service.

Industrial Ice Makers For Sale

The Importance of Industrial Ice Makers

In the bustling world of food service, medical industries, and large-scale fishing operations, Industrial Ice Makers For Sale play an essential role. These machines are the workhorses of ice production, delivering substantial quantities of ice needed daily. At Holiday Ice, we understand the critical nature of having a reliable ice supply, especially during peak demand periods. Our Arctic-Temp® Ice Machines are designed to meet these rigorous demands, ensuring that businesses never face the inconvenience of running short on ice.

Our machines are not just about quantity. We prioritize quality, using materials like Type-304 stainless steel to ensure durability and longevity. The Copeland compressors we employ are a testament to our commitment to quality, providing energy and water efficiency that stands out in the market.

Choosing the Right Industrial Ice Maker

Selecting the right Industrial Ice Makers For Sale involves understanding your specific needs. At Holiday Ice, we offer machines with capacities ranging from 2,500 to over 10,000 lbs per day. This variety means you’re sure to find a machine that perfectly matches your requirements, whether you’re a restaurant or a processing plant.

Consider the operational environment, ice production capacity needed, and maintenance requirements when making a choice. Our Arctic-Temp® line includes customizable options to ensure that each machine fits seamlessly into your workflow. This personalized approach assures peak performance and reliability, especially in Southern latitudes where heat is a constant challenge.

Energy efficiency is another crucial factor. With advanced re-circulated water technology, our machines help businesses save significantly on electricity and water costs, proving that high performance doesn’t have to come at a high price.

What Makes Our Ice Makers Stand Out?

Industrial Ice Makers For Sale from Holiday Ice have carved a niche in the market, thanks to our dedication to quality and customer satisfaction. The machines are hand-assembled and TIG welded to ensure robust construction, and the evaporators are meticulously crafted to withstand continuous use. This results in not only a reliable product but also one that consistently performs better in various conditions.

With a customer base spanning from North America to Australia, it’s evident that our commitment to personal service and quality resonates worldwide. Our customer testimonials echo the satisfaction and trust that clients place in our machines, highlighting the personalized support and educational resources we provide.

Trust in our experience, spanning over six decades, and join our family of happy customers who rely on our industrial ice makers to meet their daily demands efficiently and economically.

How to Maintain Your Industrial Ice Maker for Optimal Performance

Ensuring the longevity and efficiency of your Industrial Ice Makers For Sale from Holiday Ice requires regular maintenance. Here’s a simple guide to keep your ice makers in prime condition:

- Regularly clean the ice bin and removable parts to prevent the buildup of bacteria and mold.

- Ensure proper ventilation around the machine to prevent overheating.

- Schedule periodic checks of the water filter and replace it as necessary to maintain water quality.

- Inspect the machine’s components for wear and tear, particularly during high-demand periods.

- Rely on professional servicing for more extensive maintenance needs to keep the machine running smoothly.

Following these steps can significantly extend the life and efficiency of your machine, ensuring that your investment remains sound and productive.

What Are Some Common Questions About Industrial Ice Makers?

When considering Industrial Ice Makers For Sale, customers often have several questions:

- How much ice can I expect to produce daily? Depending on the model, capacities range from 2,500 to over 10,000 lbs per day.

- Are the machines energy-efficient? Yes, our machines utilize advanced technology to reduce energy and water consumption.

- What kind of maintenance is required? Regular cleaning, water filter replacement, and professional servicing are recommended.

- How does climate affect performance? Our machines are rated for maximum performance even in hot Southern climates.

These answers help businesses make informed decisions and select the machine that best fits their operational needs.

Exploring the World of Industrial Ice Machines

Industrial ice machines are essential for businesses that require a reliable source of ice. At Holiday Ice, we specialize in crafting durable and efficient machines. Our expertise spans over six decades, and our Arctic-Temp® Ice Machines are among the best in the industry. They are a preferred choice in many sectors, including hospitality and manufacturing, due to their high performance and low energy consumption.

The demand for industrial ice machine for sale options continues to grow, especially in regions with high ambient temperatures. Our machines are specifically designed to meet these demands by maintaining peak output even during the most challenging conditions. This commitment to quality and performance is evident in the meticulous selection of materials and the precision involved in our manufacturing process.

Our commitment to customer satisfaction is unwavering. Holiday Ice, a trusted name in the industry, ensures that every machine is not only robust but also energy-efficient. This approach not only saves costs but also supports sustainability efforts.

Why Choose Copeland Compressors?

Copeland compressors are a key component in our industrial ice machines. Known for their reliability, they ensure the machine operates efficiently under various conditions. The choice of Copeland compressors highlights our focus on utilizing high-quality components to deliver unparalleled performance.

These compressors contribute to the extended lifespan of our machines. Our customers appreciate the peace of mind that comes with knowing their investment is backed by top-of-the-line technology. Choosing an industrial ice machine for sale that incorporates these compressors means opting for reliability and consistency.

Perks of Buying Industrial Ice Machine for Sale

Purchasing an industrial ice machine for sale offers several benefits beyond immediate cost savings. It is an investment in operational efficiency for businesses that depend heavily on ice production. Our machines are designed to handle large capacities, from 2,500 to 10,000+ lbs per day, which suits various industrial needs.

- Energy-efficient operation

- Durable construction with Type-304 stainless steel

- Comprehensive customer support

- Global reach with services in North and South America, Iceland, and beyond

Holiday Ice machines also come with the assurance of comprehensive customer service and support. Our friendly staff are readily available to assist with any inquiries or technical support, ensuring your machine continues running at peak efficiency.

What Makes a Great Industrial Ice Machine for Sale?

A great industrial ice machine for sale is one that balances performance with cost-efficiency. It should offer a suitable capacity, energy efficiency, and durability. Our Arctic-Temp® Ice Machines are crafted considering these factors, providing a seamless blend of innovation and practicality.

Here’s what to look for in a quality machine:

- Assess the ice production capacity to match your business needs.

- Check energy consumption ratings to ensure cost-effectiveness.

- Inspect the build materials and components for durability.

- Evaluate the manufacturer’s reputation for reliability and service.

By addressing these aspects, buyers can ensure they’re selecting a machine that will deliver consistent results for years to come.

Insights from Industry Veterans

With over 20 years representing Holiday Ice, I’ve witnessed the evolution of industrial ice machines and their impact on businesses. Our machines, with their innovative designs, cater to diverse needs while ensuring environmental responsibility. This experience has solidified our expertise and commitment to providing exceptional customer satisfaction in the market.

Our dedication goes beyond manufacturing. We also focus on educating our clients about selecting, maintaining, and maximizing the efficiency of our machines. Through expert articles and resources, we aim to empower users to make informed decisions, ensuring that their equipment performs optimally.

Why Are Industrial Ice Machines Important?

In the world of Industrial Ice Machines, efficiency, reliability, and durability are more than buzzwords–they are critical factors that drive industries. As someone with over 20 years in the industry, I’ve seen firsthand how these machines keep businesses running, especially in high-demand sectors like food processing and hospitality. They are designed to produce large quantities of ice with minimal downtime, ensuring that businesses can meet customer needs without interruption.

Industrial Ice Machines not only support operational efficiency but also contribute to significant cost savings. By choosing energy-efficient models, businesses can reduce electricity consumption and operational costs over time. Our Arctic-Temp® models, for instance, are specifically engineered for these purposes, employing top-quality Copeland compressors and re-circulated water systems for optimal performance.

Key Components of Industrial Ice Machines

- Compressors: The heart of the ice machine, responsible for cooling the refrigerant and facilitating ice formation.

- Evaporators: Used to freeze water into ice, these need to be durable and efficient for continuous operation.

- Water Re-circulation Systems: These reduce water waste and are a hallmark of modern, eco-friendly designs like those we produce at Holiday Ice.

- Control Panels: Allow for programmable settings to adjust ice size, production rate, and maintenance alerts.

How to Choose an Industrial Ice Machine

The choice of an Industrial Ice Machine depends heavily on your specific needs. Consider the volume of ice you require–our machines cater to capacities ranging from 2,500 to over 10,000 lbs per day. It’s essential to match the machine’s capacity with your business’s peak demand periods, often dictated by seasonal fluctuations.

The environment also plays a role; machines like our Arctic-Temp® are designed to operate efficiently in warmer climates, a significant advantage for businesses in southern regions where temperature spikes can impact performance.

Lastly, consider the machine’s maintenance needs and warranty. A well-maintained ice machine can last for decades, making an investment in quality and support services, such as those we provide at Holiday Ice, a smart choice.

What Are the Benefits of Energy-Efficient Ice Machines?

Energy-efficient Industrial Ice Machines offer a multitude of benefits that extend beyond mere cost savings. These machines use less power, reducing the overall environmental impact of your business operations. This aligns with the growing consumer demand for sustainable practices.

From my experience at Holiday Ice, using high-grade components like Type-304 stainless steel and hand-assembled parts means our machines not only last longer but also maintain their energy-efficient operation over time. This results in less frequent replacements and reduced lifecycle costs.

Moreover, businesses using energy-efficient machines may qualify for rebates from local utilities, furthering financial benefits. These machines often feature advanced controls that allow for precision operation, enhancing their efficiency and performance.

Steps for Maintaining Industrial Ice Machines

Proper maintenance is key to the longevity and efficiency of Industrial Ice Machines. Here’s a simple checklist to follow:

- Regularly inspect the machine for any signs of wear or damage.

- Clean the evaporator and condenser coils to ensure efficient ice production.

- Check the water filtration system every month to prevent mineral buildup.

- Ensure the machine is level to avoid operational inefficiencies.

- Schedule annual professional maintenance to address any complex issues.

Why are industrial ice makers critical in various industries?

Industrial ice makers are essential in industries such as food service, medical fields, and large-scale fishing operations because they provide a steady supply of ice needed for daily operations. For instance, in the restaurant industry, having a reliable ice supply can mean the difference between keeping customers happy and losing business due to warm drinks. Similarly, in the medical sector, ice is crucial for preserving biological specimens or managing post-surgical swelling. Our Arctic-Temp® Ice Machines are designed to ensure businesses get an uninterrupted ice supply, even during peak demand periods.

What factors should I consider when choosing an industrial ice maker?

When choosing an industrial ice maker, consider the capacity you require based on your business’s peak demand. Our machines range from 2,500 to over 10,000 lbs per day, so there’s likely a model that fits your needs. Also, think about the environment your machine will operate in; our machines are built to perform well even in the hot climates typical of Southern latitudes. Additionally, consider the maintenance needs and energy efficiency of the machine. Energy-efficient models reduce operational costs significantly over time.

How do I maintain my industrial ice maker for optimal performance?

Proper maintenance is crucial for the longevity and efficiency of your ice maker. Regularly cleaning the ice bin and removable parts prevents bacteria buildup. Ensure there’s proper ventilation around the machine to avoid overheating, and check your water filters often for optimal water quality. During high-demand periods, inspect components for wear and tear. Annual professional maintenance can address more complex issues and keep the machine running smoothly.

Why is energy efficiency important in industrial ice machines?

Energy efficiency in industrial ice machines leads to cost savings and environmental benefits. Machines that use advanced technology like re-circulated water systems help businesses save on electricity and water costs, which can be substantial over the machine’s life. At Holiday Ice, we prioritize energy-efficient designs, not only to lower your operational costs but to minimize your business’s environmental impact. Plus, using energy-efficient machines can often make businesses eligible for utility rebates.

What are the key components of an industrial ice machine and their importance?

The key components include compressors, evaporators, water re-circulation systems, and control panels. Compressors cool the refrigerant and are crucial for ice formation; they’re the heart of the machine. Evaporators freeze the water into ice and must be highly durable for continuous use. Water re-circulation systems reduce water waste, highlighting eco-friendly design. Control panels offer programmable settings, allowing you to adjust production rates and receive maintenance alerts, ensuring efficiency and reliability.

Common concerns about buying industrial ice makers?

Many buyers worry about whether their ice maker will meet their daily production needs. Our machines come with capacities from 2,500 up to over 10,000 lbs per day, tailored to various industry demands. Another common concern is the energy efficiency of the machine, to which we have addressed with re-circulated water systems and Copeland compressors for optimal performance. Maintenance requirements are also important; regular cleaning and professional servicing help keep the machine in top condition. Climate can impact performance, but our machines are built to excel even in warmer conditions.

What are the benefits of purchasing an industrial ice machine?

Purchasing an industrial ice machine increases operational efficiency, reduces downtime, and can significantly cut costs through energy-efficient designs. Our machines provide reliable and high-capacity ice production, essential for businesses that rely on a continuous ice supply. Not to mention, with our high-quality components like Type-304 stainless steel and customer support, your investment is protected, ensuring your machine performs reliably for years. This all results in enhanced operational efficiency and peace of mind.

What insights can industry veterans provide about industrial ice makers?

Industry veterans often emphasize the critical balance between performance and cost-efficiency. Over the years, the focus has shifted towards energy-saving designs, which not only save money but are environmentally responsible. This is particularly true with our Arctic-Temp® Ice Machines, which offer high-quality performance combined with sustainability. Additionally, experience tells us that customer support and education are invaluable, which is why we provide comprehensive resources to help our clients make informed decisions and maintain their equipment effectively.

Where can I find more information or purchase industrial ice machines?

Various reputable sources provide further insights into industrial ice machines. Websites like Home Depot and Hoshizaki Ice Maker offer detailed product listings. For specialized options, Iron Mountain Refrigeration and Ice Machines Plus are excellent resources. Exploring these can help you understand different options and find a machine that precisely meets your needs.

Resources

- Food and Drug Administration (FDA) – The FDA website provides information on food safety regulations and guidelines for businesses in the food service industry.

- U.S. Department of Energy – The Department of Energy offers resources on energy efficiency, including tips on reducing energy consumption in industrial operations.

- Advanced Manufacturing Office (AMO) – AMO provides information on advanced manufacturing technologies and practices that can benefit industrial ice machine production.

- Environmental Protection Agency (EPA) – The EPA website offers insights on environmental regulations and sustainability practices for businesses to consider in their operations.

- National Institute of Standards and Technology (NIST) – NIST provides standards and measurement tools that can help ensure the quality and performance of industrial ice machines.

What We Offer

OurIce Machines

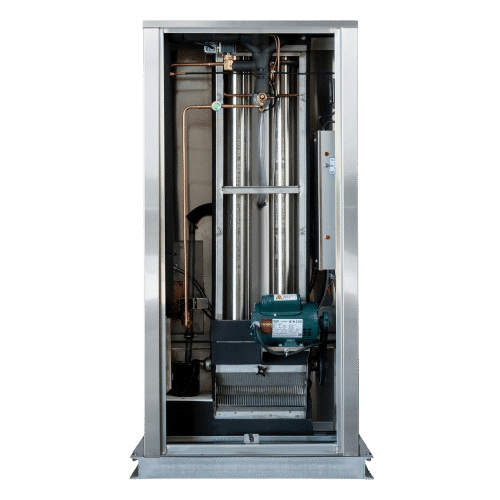

ARCTIC-TEMP® MODEL 500

- 2,500 lbs. of hard cracked ice in 24hrs. (907 Kg.)

- Highly efficient Copeland Compressor

- Double-Walled Vertical Tube Evaporators For Maximum Production

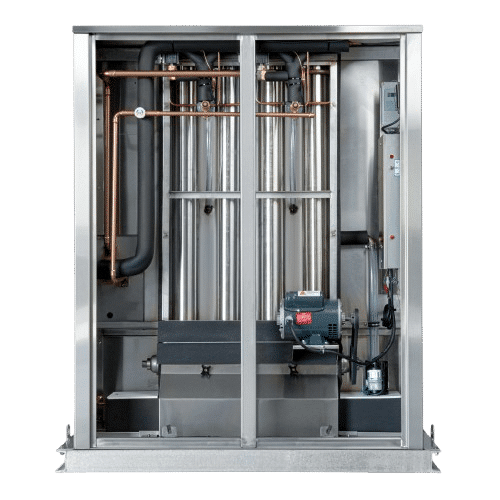

ARCTIC-TEMP® MODEL 750

- 4,500 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

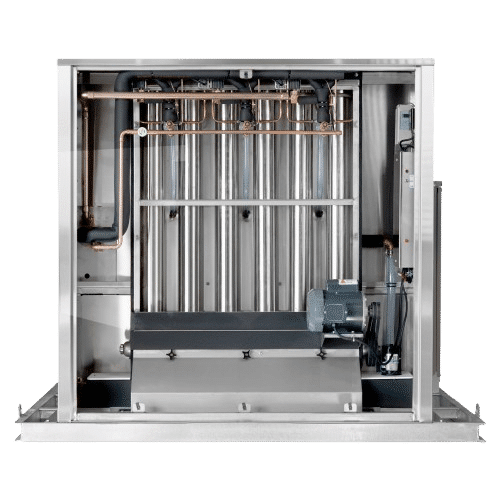

ARCTIC-TEMP® MODEL 1000

- 6,500 lbs. of hard cracked ice in 24 hrs. (2,948 Kg.)

- Highly efficient Copeland Discus Compressor

- Double-Walled Vertical Tube Evaporators

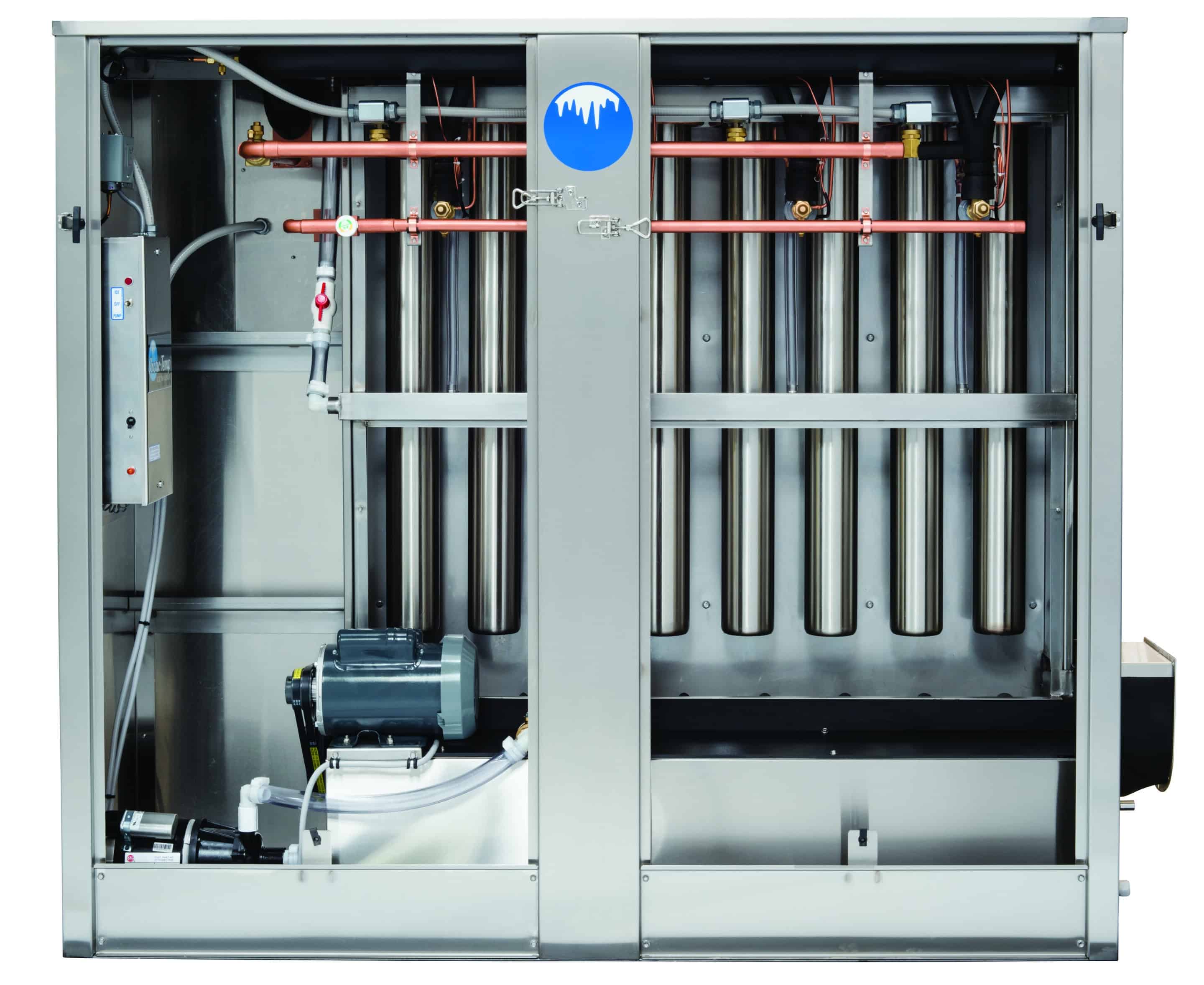

ARCTIC-TEMP® MODEL 1500

- 10,000 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

Ice Machine Manufacturing

ProductionProcess

- Our ice machines are built using high-quality Type-304 stainless steel, unlike other companies that use lower-grade alloys.

- Machines are hand-assembled and TIG welded for precision.

- Stainless steel evaporators are hand-formed and welded for durability.

- The ice-making section is fully assembled before being combined with the condenser and compressor.

- We use COPELAND compressors, known for their quality, industry-leading warranty, and widespread parts distribution.

- Our evaporators use a double-surface concave freezing technique with vertical tubes for faster, more efficient ice production and improved cooling.

- The freezing zone contains no moving parts, avoiding issues related to gears or motors.

- Standard, easily replaceable components are used, except for the evaporator, which simplifies maintenance after the warranty period.

- All machines are leak and vacuum tested, factory charged with refrigerant, and thoroughly calibrated for reliable performance from the start.

Years in Business

Ice Machines Sold

Repeated Customers

Countries Served

Global Network

CountriesWe Serve

North America

- • USA

- • Canada

- • Mexico

- • Bahamas

- • Anguilla

- • Cayman Islands

- • Jamaica

- • Dominican Republic

- • St. Lucia

Central America

- • Belize

- • Honduras

- • Nicaragua

- • Guatemala

- • El Salvador

South America

- • Guyana

- • Suriname

- • Ecuador

South America

- • Guyana

- • Suriname

- • Ecuador

Aruba

Iceland

Philippines

Oceania

- • American Samoa

- • Australia

Client Reviews

Testimonials

Discover firsthand experiences from our satisfied customers about their Arctic-Temp® ice machines.