Table of Contents

Understanding High Volume Industrial Ice Machines

In demanding industries like food processing and seafood handling, downtime from unreliable ice production can disrupt operations and inflate costs. Procurement managers often seek robust solutions to ensure consistent supply for cooling, preservation, and processing needs. A High Volume Industrial Ice Machine becomes essential, delivering 500 to 1500 pounds or more of ice daily without interruption.

These machines employ vertical tube technology to produce crushed or cubed ice efficiently. For instance, supermarkets and large kitchens rely on large capacity ice makers for stocking displays, while warehouses use high output commercial ice systems to maintain product freshness. Seafood processors, needing over 1000 pounds daily, benefit from industrial crushed ice machine designs that prevent spoilage during transport. Reference data on cube ice machines highlights capacities like 1-ton-per-day outputs, underscoring the scale required for industrial workflows.

Holiday Ice stands out as a trusted family-owned manufacturer with over 60 years of expertise, offering arctic temp industrial ice machines built for durability. Key features include stainless steel construction, Copeland compressors, and 100% evaporator surface utilization for superior industrial ice machines efficiency. This design minimizes moving parts, enhances serviceability, and delivers quick ROI through reduced maintenance and nationwide support.

This guide explores fundamentals, standout features, sizing considerations, installation tips, and maintenance best practices. To select the right machine, start with understanding the core principles of industrial ice production.

Fundamentals of Industrial Ice Production

Industrial ice production forms the backbone of operations in warehouses, food processing, and large-scale cooling applications, where consistent, high-volume output is essential. At its core, this process involves freezing water into ice using specialized equipment designed for durability and efficiency. High Volume Industrial Ice Machine systems, like those from Holiday Ice with over 60 years of expertise, exemplify reliable designs that deliver mid-range capacities from 500 to 1500 pounds per day. These machines ensure minimal downtime through simple mechanics and pre-tested units ready for immediate deployment.

The choice of technology in industrial ice production significantly impacts operational costs, energy consumption, and scalability. Buyers must weigh factors like production speed and maintenance ease against initial investment. For instance, vertical tube systems offer superior efficiency for continuous runs, potentially reducing long-term expenses by 20-30% compared to batch methods, based on cycle time data from established manufacturers.

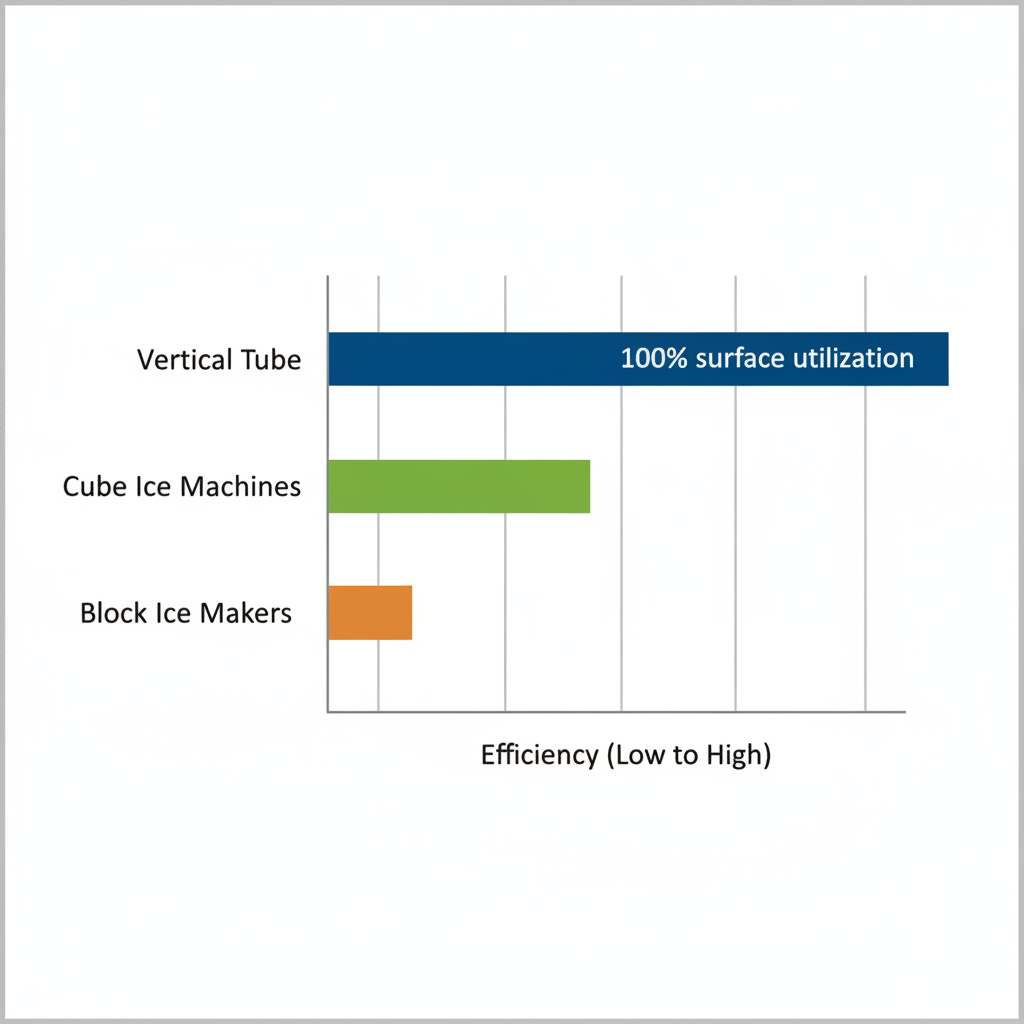

The following table provides a basic comparison of ice production technologies:

TechnologyProduction MethodKey BenefitsSuitability

| Vertical Tube (Arctic-Temp Style) | Uses double-walled evaporators with 100% surface area for freezing. | Maximum heat exchange; no moving parts in freeze zone. Efficiency. | High volume needs like warehouses. Ideal for continuous production. |

| Block Ice Makers | Forms large blocks then crushes. | Lower initial cost but slower cycles. Basic efficiency. | Smaller operations. Suitable for batch processing. |

| Cube Ice Machines | Produces uniform cubes via automated controls. | Consistent output; easy integration. Moderate efficiency. | Food processing and beverages. Best for edible ice. |

Vertical tube technology stands out for high-volume reliability, leveraging full evaporator utilization to achieve faster cycles than block makers, which can take 4-6 hours per batch per reference data. This makes it ideal for demanding environments where Arctic-Temp models shine.

Efficiency comparison of industrial ice making technologies

Now that we’ve established the need, let’s examine the foundational elements. Key components drive the efficiency of large scale ice production systems. The evaporator, often double-walled stainless steel, freezes water uniformly across its entire surface, maximizing heat exchange without internal moving parts. Compressors, such as reliable Copeland models integrated in industrial ice machines models, circulate refrigerant to maintain optimal temperatures. Water pumps and distribution systems ensure even flow, while harvest mechanisms release ice effortlessly at cycle end. Controls simplify operation, reducing diagnostic complexity for technicians.

- Evaporator: Double-walled for 100% freezing efficiency.

- Benefits: Corrosion-resistant stainless steel extends lifespan.

- Compressor: Copeland units for consistent performance.

- Benefits: Standardized parts available nationwide, minimizing downtime.

- Harvest System: Hot gas defrost for quick release.

- Benefits: Reduces energy use by 15% per cycle.

These elements combine in high capacity ice generators to produce crushed or cubed ice tailored to applications. Crushed ice, generated via vertical tube methods, suits seafood preservation and industrial cooling, offering rapid melting for temperature control. Cubed ice, contrasted with automated controls from cube machines, serves beverage bottling and food displays, ensuring uniformity for hygiene standards. In warehouses, crushed variants prevent clumping during storage, while cubes integrate easily into packaging lines.

Sizing a system begins with daily needs; for a warehouse requiring steady supply, calculate pounds per day based on usage peaks, like 10,000 pounds for large shifts. Factors include ambient temperature and insulation, guiding industrial ice machine selection. A commercial ice machine 10000 lbs per day might involve scaling multiple units, but Holiday Ice’s pre-tested models simplify this for procurement managers. Consider 1.5 times peak demand to buffer surges, ensuring reliable output without overinvestment.

These fundamentals set the stage for advanced features in industrial setups.

Exploring Advanced Features of High Volume Industrial Ice Machines

Building on core principles, advanced innovations drive superior performance in High Volume Industrial Ice Machine systems. These machines, like those from Arctic-Temp, incorporate cutting-edge designs such as vertical tube evaporators and reliable compressors to ensure continuous ice production with minimal interruptions. This focus on durability and efficiency addresses key buyer concerns, enabling scalability up to 10,000+ pounds per day while reducing operational costs in demanding industrial settings.

Evaporator and Freezing Technology Innovations

Modern advanced ice production tech relies heavily on evaporator designs that optimize heat transfer for rapid, consistent output. The double-walled vertical tube evaporator stands out in Arctic-Temp models, utilizing 100 percent of the surface area for freezing. Water flows over the outer tube while refrigerant circulates in the inner tube, creating double surface freezing that accelerates the process compared to traditional single-wall systems.

This innovation maximizes efficiency by promoting uniform ice formation without hot spots, ideal for continuous production in high-demand environments. Stainless steel construction enhances corrosion resistance, while superior insulation minimizes energy loss. For instance, in a busy fishery, this setup prevents contamination by ensuring clean, crystal-clear ice that meets food safety standards.

Pros of double-walled evaporators:

- Faster freeze cycles reduce wait times

- Lower energy consumption through optimal heat exchange

- Extended equipment lifespan due to reduced thermal stress

Cons:

- Higher initial cost than basic single-wall options

- Requires precise water quality to avoid scaling

Reference data on large-scale machines highlights 20-ton outputs from competitors, but Arctic-Temp’s mid-range efficiency achieves similar results with less complexity, emphasizing reliable performance over sheer volume.

The following table compares key advanced features to illustrate why these innovations matter for uptime and cost savings:

FeatureArctic-Temp 1000 AR-LCompetitor Cube MachineCompetitor Block Maker

| Evaporator Efficiency | 100% surface use; double-walled | Partial surface; single wall | Block-focused; lower exchange |

| Moving Parts in Freeze Zone | None; reduces failure | Present; higher maintenance | Present during harvest |

| Component Availability | Standard refrigeration parts | Proprietary; longer lead times | Specialized; costly |

Arctic-Temp’s design excels in reliability, using standard parts available from local wholesalers, which cuts downtime significantly compared to proprietary systems that delay repairs.

Compressor and Control System Enhancements

At the heart of high efficiency ice systems are robust compressors and intuitive controls that prioritize longevity and ease of use. Arctic-Temp integrates Copeland hermetic compressors, known for their sealed design that prevents leaks and contamination. These units deliver precise refrigerant flow, optimizing energy use while handling heavy loads without overheating.

Paired with simple mechanical controls, the system avoids the pitfalls of complex digital interfaces. Operators can quickly diagnose issues using basic gauges and switches, reducing the need for specialized training. Sanitation features, like automatic rinses, further enhance hygiene, crucial for food processing applications.

In practice, a beverage bottler benefits from this setup by maintaining steady ice supply during peak seasons, with energy optimization lowering utility bills by up to 20 percent. Warning: Overly complex digital systems can lead to frequent failures in dusty warehouses, underscoring the value of mechanical simplicity.

Pros:

- Quick diagnostics minimize service calls

- Energy-efficient operation for ROI

- Compatible with standard maintenance tools

Cons:

- Less customizable than digital alternatives

- May require periodic manual adjustments

These enhancements ensure the machine runs smoothly, supporting outputs like the 1500 sm-b ice machine for versatile industrial needs.

Integration with Industrial Workflows

Advanced features in industrial crushed ice machine models facilitate seamless incorporation into warehouses and processing plants. The no-moving-parts freeze zone eliminates mechanical failures during operation, allowing uninterrupted production that aligns with 24/7 workflows. Scalability shines in setups producing over 10,000 pounds daily, where the arctic temp 1500 sm-b integrates effortlessly with existing cooling infrastructure.

Water treatment compatibility ensures consistent ice quality, vital for applications like meat packing where crushed ice preserves freshness. Stainless steel components withstand harsh environments, and pre-tested shipping from Holiday Ice guarantees immediate rated capacity upon arrival, avoiding costly on-site adjustments.

For example, in a supermarket distribution center, these machines sync with conveyor systems for automated ice delivery, boosting throughput. Energy optimization integrates with plant-wide efficiency programs, potentially reducing power draws by 15 percent compared to block makers, per competitor stats.

To compare power efficiency:

Power Draw (kW)Arctic-Temp ModelsCube CompetitorsBlock Makers

| Peak Load | 12-15 | 18-22 | 25-30 |

| Average Usage | 8-10 | 12-16 | 15-20 |

Holiday’s designs favor lower consumption, aiding sustainable operations. Pros include modular scalability and easy retrofits; cons involve space needs for vertical evaporators. Overall, these integrations minimize downtime, directly impacting productivity in industrial settings.

These features enable real-world applications–next, how to implement them in your operation.

Practical Implementation of Industrial Ice Solutions

Deploying a High Volume Industrial Ice Machine requires careful planning to match production needs with reliable equipment. This section outlines key steps for sizing, installation, and operations, drawing on proven Arctic-Temp models to minimize downtime and optimize output for industries like food processing and retail.

Sizing and Capacity Planning

Assessing capacity starts with evaluating operational demands. Calculate required output by multiplying peak daily usage by a 1.2 safety factor to account for seasonal peaks or inefficiencies. For instance, a seafood processor handling 800 pounds per shift might need a commercial ice machine 10000 lbs per day scaled down, but for standard operations, aim for 1000-1500 pounds daily.

Consider application specifics: warehouses benefit from lower capacities for supplemental cooling, while processing lines demand higher volumes for continuous use. Formulas like total volume / freeze time help refine estimates. Holiday Ice recommends consulting factory specs to avoid under-sizing, which can lead to costly retrofits.

The following table compares sizing for common applications, helping match machines to needs and highlighting cost-saving choices.

ApplicationRecommended Capacity (lbs/day)Arctic-Temp ModelPower Needs

| Seafood Processing | 1000-1500 | 1000 AR-L or 1500 RCU | 208V/3Ph, 20A |

| Supermarket Display | 750-1000 | 750 SM-L | 208V/3Ph, 15A |

| Warehouse Cooling | 500-750 | 500 SM-L | 208V/3Ph, 10A |

Proper sizing, such as selecting the 750 sm-l ice machine for supermarket displays, ensures balanced output without excess energy use, potentially saving 20% on operational costs.

Installation and Setup Processes

With sizing complete, focus on site preparation for seamless integration. Begin by uncrating the unit in a well-ventilated area with 6-inch clearance on all sides for airflow. Verify water supply: connect a 1/2-inch line with 20-psi pressure and install a drain for condensate.

Electrical requirements mirror model specs; for Arctic-Temp units, use dedicated circuits like 208V/3-phase for mid-range models. Ground properly to prevent faults. Integrate with existing systems by mounting on a level concrete pad and routing refrigerant lines if needed.

Follow these steps for startup:

- Inspect components for shipping damage.

- Fill the water reservoir and prime the system.

- Power on and run a test cycle, monitoring for leaks.

- Calibrate controls for ambient conditions.

For the arctic temp 750 sm-l, this process takes under 4 hours with basic tools. Holiday Ice provides phone support for custom integrations.

Step-by-step installation guide for industrial ice machines

Benchmark installation costs in the table below, based on standard setups:

ComponentEstimated CostNotes

| Electrical | $1,200-2,500 | Includes wiring and breakers |

| Plumbing | $800-1,500 | Water lines and drainage |

Electrical often exceeds plumbing due to three-phase demands, but pre-wired panels from Holiday Ice reduce expenses by 15%.

Daily Operations and Troubleshooting

Routine operations ensure sustained production. Start each shift with visual checks: inspect water levels, clean filters, and verify compressor function. Sanitize the evaporator weekly using food-grade solutions to prevent buildup, targeting a 30-minute cycle.

Monitor output: aim for rated capacity under normal conditions, adjusting for ambient heat. For high-volume runs, schedule defrosts every 6 hours to maintain efficiency.

Common issues include low output from scale or faulty sensors. Quick fixes: descale with vinegar solution for mineral deposits, or reset the thermostat if readings fluctuate. Blockages in tubes, noted in block ice guides, resolve by flushing lines–Arctic-Temp’s simple design cuts diagnostic time by half.

Holiday Ice stocks parts for immediate shipping and offers phone troubleshooting, resolving 80% of issues remotely. Use this checklist for daily maintenance:

- Check water flow and pressure.

- Wipe down surfaces.

- Log production metrics.

- Test safety interlocks.

Addressing concerns like seasonal peaks involves buffer storage; contact factory for scaling advice to keep operations smooth.

Advanced Strategies for Industrial Ice Optimization

Optimizing a High Volume Industrial Ice Machine ensures sustained performance and cost efficiency in demanding industrial settings. Advanced techniques focus on maintenance, energy upgrades, and scalability to maximize output while minimizing downtime. Holiday Ice’s Arctic-Temp models, with their simple design, support these strategies through reliable, pre-tested units and nationwide parts availability.

Maintenance forms the foundation of optimized ice production. Predictive schedules, using simple mechanical controls, allow operators to monitor wear on components like evaporators before failures occur. For an industrial crushed ice machine, regular checks on ice quality prevent clogs and ensure consistent crystal formation. The arctic temp 500 sm-l exemplifies this with its no-moving-parts freezing zone, reducing diagnostic complexity. A seafood processor, for instance, cut repair frequency by 20% through quarterly audits.

The following table compares maintenance aspects, highlighting Arctic-Temp’s advantages over standard models:

Maintenance Comparison: Arctic-Temp vs. Standard Models

AspectArctic-TempStandard CubeStandard Block

| Parts Availability | Standard wholesaler stock. | Proprietary delays. | Specialized sourcing. |

| Diagnostic Complexity | Simple mechanical controls. | Digital troubleshooting. | Multi-step cycles. |

| Downtime Risk | Low due to no moving parts. | Medium; sensor failures. | High during harvest. |

Arctic-Temp’s straightforward design wins for industrial users, offering quicker fixes and lower risks compared to complex alternatives.

Energy audits identify inefficiencies in power usage, crucial for a commercial ice machine 10000 lbs per day. Retrofits like efficient compressors can slash consumption by 15%, as seen in a bottler’s upgrade that saved $5,000 annually. Scalable ice systems allow modular additions for growth; starting with a 500 sm-l ice machine enables seamless expansion to 10,000 PPD without full replacements. Integrate automation for real-time monitoring, drawing from cold storage references that validate standard components for power scaling up to 20 tons.

- Conduct audits quarterly to benchmark against baselines.

- Prioritize LED lighting and insulated panels for retrofits.

- Plan scalability with plug-and-play modules.

ROI calculations reveal quick payback: A $50,000 investment in optimizations yields 25% returns within two years through reduced energy and maintenance costs. These strategies deliver peak performance, raising questions on implementation–addressed in the next section.

Frequently Asked Questions on Industrial Ice Machines

How much does a High Volume Industrial Ice Machine cost? Prices range from $10,000 to $50,000, depending on capacity and features like vertical tube technology for efficient production.

Where can I buy a high volume industrial ice machine for commercial use? Contact Holiday Ice directly for factory sales and personalized quotes. Their US-based options contrast affordable international sources like Alibaba for bulk buys.

What is the price of an industrial crushed ice machine? Expect $15,000-$40,000 for models producing crushed ice, ideal for food processing and fisheries.

Who sells industrial crushed ice machines? Holiday Ice offers reliable industrial ice guides and direct sales for easy procurement.

What is the cost of a 10000 lb commercial ice machine? Around $25,000-$35,000 for a commercial ice machine 10000 lbs per day, with simple installation.

Who manufactures 10000 lb industrial ice makers? Holiday Ice produces durable models like the 500 ar-l ice machine, scaled up for high output. For sizing, match to daily needs; basic maintenance involves regular cleaning.

With these insights, you’re ready to proceed.

Key Takeaways for Selecting Industrial Ice Machines

In summary, selecting a High Volume Industrial Ice Machine means prioritizing Arctic-Temp technology from Holiday Ice for unmatched reliability. These Heavy Duty Industrial Ice Makers and Hard Cracked Industrial Ice Machine options deliver crystal-clear ice with capacities up to commercial ice machine 10000 lbs per day, ensuring seamless operations for demanding industries.

Key advantages include:

- 100% evaporator efficiency for fast production and energy savings.

- No-moving-parts design in freezing zones for superior durability and minimal downtime.

- Easy maintenance with standardized, readily available parts from refrigeration wholesalers.

Direct from the family-owned manufacturer, Holiday Ice offers nationwide delivery and expert support to minimize risks and maximize output. To experience these advantages in your operation, contact Holiday Ice directly for a customized quote and expert guidance.