Arctic-Temp® Ice Makers by Holiday Ice, Inc.

All Purpose Industrial Ice Machines From 2,500 to 10,000 lbs Per Day

Holiday Ice is a manufacturer of specialized, mid-range capacity commercial ice machines for industrial applications. For over 60 years, our commitment to personal service and outstanding quality has created a family of happy customers.

The Best Value

Our machines are efficient, economical, and made from the highest quality material and components, including top-of-the-line Copeland compressors.

Energy & Water Efficient

Our machines use re-circulated water, which saves you money on water costs. They also use less electricity than other models at the same capacity.

Realistically Rated

Our machines operate in Southern latitudes and are realistically rated for maximum performance during the scorching summer months when demand is greatest.

60+

years of experience

Who We Are

Holiday Ice,Quality You Can Count On.

Our Arctic-Temp® Ice Machines are legendary for providing years of reliable performance, even in the most grueling climates and conditions. Holiday Ice is a family-owned business, and we serve our customers with a personal touch.

Personalized Customer Service

Instead of some pre-recorded message, you’ll be greeted by a member of our friendly staff.

Top-Rated Copeland Compressors

No other manufacturer offers our combination of quality, longevity, price and service.

Bulk Ice Makers

The Role of Bulk Ice Makers in Industry

In the bustling world of hospitality and food service, Bulk Ice Makers play a crucial role, providing the essential cooling power needed to keep operations running smoothly. As someone with over 20 years of experience at Holiday Ice, I’ve seen firsthand how these machines can make or break a business’s efficiency. Our Arctic-Temp® Ice Machines are a testament to the importance of reliable ice production, especially during peak seasons when demand soars.

Why Energy Efficiency Matters

Energy efficiency is not just a buzzword; it’s a vital consideration in the design of modern Bulk Ice Makers. By choosing machines that utilize Copeland compressors, we ensure our equipment is both powerful and economical. This choice aligns not only with environmental standards but also with the bottom line of our clients. When you’re producing over 10,000 lbs of ice per day, like our top-tier models, every saving counts!

Clients often express their satisfaction with savings on both energy and water bills, thanks to innovations such as recirculated water systems. These systems decrease waste and improve efficiency, ensuring that the Arctic-Temp® machines are a smart investment for businesses worldwide.

How to Choose the Best Bulk Ice Makers for Your Needs

Selecting the right Bulk Ice Makers involves understanding your business’s unique ice demands. With my extensive experience, I often advise clients to consider these steps:

- Assess Capacity Needs: Calculate your daily ice usage during peak times to determine your machine’s capacity.

- Evaluate Energy Efficiency: Opt for models that offer energy-saving features to reduce long-term costs.

- Consider Reliability: Invest in brands with a track record of reliability, like Holiday Ice’s Arctic-Temp® machines.

- Check for Support: Ensure the manufacturer provides robust customer support and resources.

By following these steps, you can confidently choose a Bulk Ice Maker that will support your business’s growth and efficiency.

Are There Solutions to Common Bulk Ice Makers Problems?

Bulk Ice Makers, despite their reliability, can occasionally face issues. The most common solution often lies in regular maintenance. Routine cleaning and servicing can prevent most problems before they start. At Holiday Ice, we emphasize the importance of a maintenance schedule that includes:

- Regular cleaning to prevent scale buildup

- Check-ups on compressor and water systems

- Immediate repairs on leaks or unusual noises

These practices ensure longevity and peak performance, making your investment worthwhile over the years.

What Qualifies as a Bulk Ice Makers Emergency?

An ice maker emergency typically involves a complete breakdown during peak demand periods. This scenario requires immediate action to avoid operational disruptions. As a proactive measure, having backup supplies or maintenance contracts can alleviate potential downtime.

We often recommend partnering with service providers who offer 24/7 support to handle unexpected emergencies swiftly. This approach minimizes potential damage to your business reputation and financial losses.

The Importance of a Bulk Ice Maker in Industrial Settings

As someone with over 20 years of expertise in the commercial ice machine industry, I’ve witnessed firsthand the essential role a Bulk Ice Maker plays in industrial applications. These machines are critical assets for businesses requiring large volumes of ice, especially during peak seasons.

Industrial operations, particularly in warmer climates, demand ice machines with substantial capacity and reliability. Our Arctic-Temp® Ice Machines serve clients globally, guaranteeing robust performance, thanks to high-quality materials like Type-304 stainless steel and top-notch Copeland compressors.

A Bulk Ice Maker not only supports uninterrupted operations but also enhances energy efficiency. By utilizing re-circulated water, our machines ensure minimum water wastage, a feature that aligns with modern sustainability goals. This is why companies across North America, Australia, and beyond rely on our equipment.

Choosing the Right Bulk Ice Maker

When selecting a Bulk Ice Maker, capacity is key. Our range spans from 2,500 to over 10,000 pounds per day, catering to diverse industrial needs. Understand your daily ice requirements to avoid undersizing or oversizing your equipment.

Consider the operating environment. Our machines are notably rated for high efficiency in Southern latitudes, perfect for businesses dealing with intense heat. Reliability during scorching summers is paramount, and this is where our Arctic-Temp® technology excels.

Don’t overlook maintenance and support. Our clients consistently praise our personalized customer service. From installation advice to troubleshooting, our experienced team is always ready to ensure your Bulk Ice Maker continues to perform at its best.

Lastly, prioritize energy efficiency. Opt for models with COPeland compressors renowned for their durability and low energy consumption. This not only reduces operational costs but also contributes positively to your business’s carbon footprint.

Common Issues and Solutions

Even the most reliable Bulk Ice Maker may encounter issues. Here are common problems and their solutions:

- Ice Production Slowdown: Ensure the machine is not overloaded and check water supply lines for blockages.

- Noise Levels: Check for any loose components or call for professional servicing if unusual noises persist.

- Ice Quality: Regular cleaning of the machine’s interior and the use of quality water filters can resolve ice clarity issues.

Proactive maintenance, like periodic inspections and following cleaning protocols, can prevent most issues from arising, ensuring longevity and efficiency in your ice production.

Why Choose Holiday Ice for Your Bulk Ice Maker

At Holiday Ice, our commitment to quality and customer satisfaction is unmatched. With over 60 years in the industry, our Bulk Ice Maker machines are crafted to meet the highest standards. We employ precise hand-assembly techniques and advanced welding technologies to ensure each machine’s durability and longevity.

Our global client base, including areas as diverse as Iceland and the Philippines, benefits from our energy-efficient designs. This dedication to quality and the environment underscores our pledge to offer innovative solutions that are both economical and environmentally friendly.

We pride ourselves on our exceptional customer support. Our knowledgeable staff is always available to help you select the right Bulk Ice Maker for your needs. Let us show you why clients worldwide choose Holiday Ice as their trusted partner in ice production.

How to Maintain Your Bulk Ice Maker for Optimal Performance

Maintaining a Bulk Ice Maker is crucial for optimal performance and longevity. Here’s how you can achieve that:

- Regular Cleaning: Clean the ice maker every few months to prevent buildup of minerals and mold. Use approved cleaning solutions for best results.

- Check Filters: Regularly inspect and replace water filters to ensure ice quality and machine efficiency.

- Inspect Components: Regularly check the machine’s components for wear and tear. Replace parts as needed to avoid downtime.

- Professional Servicing: Schedule annual maintenance checks with a qualified technician. This helps identify potential issues before they become costly repairs.

Implementing these practices will ensure your machine runs smoothly, providing consistent ice production and extending the lifespan of your equipment.

What Makes a Quality Bulk Ice Maker?

A quality Bulk Ice Maker is defined by several key components: high-grade materials, efficient compressors, and precise manufacturing processes. At Holiday Ice, we incorporate Type-304 stainless steel and Copeland compressors to ensure our machines are not only durable but also energy-efficient.

Our hand-assembled and TIG-welded machines signify a dedication to craftsmanship often lost in mass production. We go the extra mile to ensure our products meet stringent performance standards, ensuring reliable operation even in challenging environments.

With precise engineering and a focus on quality, we ensure that our clients receive the best Bulk Ice Maker solutions tailored to their specific needs, standing out as a leader in industrial ice production.

Crafting Clear Ice: The Production Process

Large Scale Ice Production is an intricate dance of precision, efficiency, and artistry. At Holiday Ice, Inc., we’re particularly proud of our Arctic-Temp® Ice Machines, and the journey of ice production is where the magic happens. It all begins with the use of high-quality Type-304 stainless steel for the construction of our machines, ensuring durability and precision. Our hand-assembled machines are TIG welded, a process known for its strong and precise joints, critical for the longevity of the equipment.

The heart of our production is the use of directional freezing, a method cherished for its ability to create crystal-clear ice. Unlike traditional methods, this technique ensures pure ice formation by freezing water from one direction, expelling impurities as it solidifies. This is crucial in maintaining the clarity and quality that our clients expect from large scale ice production. The use of Copeland compressors, renowned for their quality and reliability, completes the equation, ensuring that our machines operate at peak performance.

In the world of industrial applications, our machines provide solutions by producing up to 10,000+ lbs of ice per day. This capability meets the demands of clients across global markets, from the sunny latitudes of Southern America to the frosty terrains of Iceland and beyond. Our commitment to excellence extends beyond production; it includes creating a seamless partnership with our clients by offering personalized customer service.

Why Is Clear Ice Essential?

Clear ice is not just aesthetically pleasing; it embodies the essence of quality. For businesses in the hospitality sector, clear ice adds an element of sophistication to any drink, elevating the consumer’s experience. Imagine serving a high-end cocktail with cloudy, impurity-laden ice; it can detract from the beverage’s appeal. Large scale ice production that consistently yields clear ice meets this exact need for premium presentation.

From an operational perspective, clear ice has benefits beyond the aesthetic. Its slower melting rate compared to traditional ice contributes to maintaining the intended flavor profile of a drink longer. In industrial applications where precision and consistency are key, such as in chemical processing or food preservation, clear ice ensures that processes are not compromised by the unpredictability of lesser quality ice.

Unique Features and Benefits of Our Ice Machines

Crafted for performance and efficiency, our Arctic-Temp® Ice Machines are designed with several standout features. First, the integration of re-circulated water systems saves on water consumption, a significant advantage given current environmental concerns. Our machines also boast enhanced energy efficiency, using less electricity than comparable models, which aligns with the industry’s shift towards sustainability.

Another vital feature is their real-world rating for maximum performance in Southern latitudes. Perfectly adapted to handle the high demands of scorching summer months, they provide a reliable source of ice when it’s needed most. Our machines are available in various capacities, ranging from 2,500 to over 10,000 lbs per day, offering our clients the flexibility to choose a solution that aligns with their unique operational needs.

- High-quality Type-304 stainless steel construction

- Energy-efficient Copeland compressors

- Hand-assembled and TIG welded for durability

- Re-circulated water systems for reduced consumption

How Can I Maximize Ice Production Efficiency?

To ensure your large scale ice production runs seamlessly, there are a few tips that can be adhered to for maximum efficiency. First, regular maintenance of the machines is crucial. Routine checks and cleaning help avoid unexpected breakdowns, which could disrupt operations. Secondly, calibrate your machines to match your specific altitude and temperature needs, particularly if operating in varied geographic conditions.

- Perform regular maintenance checks on all machinery components.

- Ensure the water source is clean and filtered to prevent impurities in ice production.

- Calibrate machines specifically for the operational altitude and ambient temperature.

- Train staff on optimal loading and unloading techniques to prevent damage.

Holiday Ice, Inc. offers not just machinery, but a partnership that includes guidance on maintaining efficiency and safety. Our expert articles and support resources are valuable tools for operators aiming to keep operations smooth and effective. In the dynamic field of commercial ice production, staying ahead with the right practices is key to consistent outcomes.

What Makes Our Customer Service Stand Out?

At the heart of Holiday Ice, Inc. is a commitment to personalized service, an element often missing in large scale ice production. Our clients are our extended family, and we ensure that they can count on us beyond just providing equipment. Our knowledgeable staff offer expert advice, addressing any inquiries or service support needs promptly and professionally.

We understand that each client’s requirements could differ, and thus, we tailor our services to meet these unique needs. Whether it’s setting up a new system or troubleshooting an existing one, our team is ready to provide assistance, drawing from over 60 years of industry experience.

Client testimonials speak volumes about our dedication, as many express satisfaction with the reliability and performance of our Arctic-Temp® Ice Machines. Operating in diverse climates worldwide from the Philippines to Australia, our machines deliver consistent results, and our support network ensures client peace of mind.

In an industry where reliability is non-negotiable, our approach to customer service sets us apart. By fostering strong relationships, we build trust and ensure that our clients are not only satisfied but delighted with their choice of Holiday Ice, Inc.

What are common concerns when choosing a commercial ice maker?

When selecting a commercial ice maker, many business owners worry about efficiency, reliability, and long-term costs. It’s essential to select a machine that matches your daily ice production needs, especially during peak times. Energy efficiency should also be a priority; machines with advanced compressors like our Copeland compressors can significantly reduce electricity bills. Reliability is another common concern, as unexpected downtime can impact operations. We recommend investing in a reputable brand with a history of durability. Consider how the ice maker will perform in your specific climate, especially in warmer areas, ensuring it maintains efficiency during high temperatures.

Have you ever wondered how much ice your business truly needs? Consider calculating your peak daily usage to ensure you’re not undersizing or oversizing your equipment.

Are there misconceptions about the maintenance of ice makers?

Absolutely! A common misconception is that ice makers are maintenance-free. In reality, regular cleaning and servicing are crucial to avoid issues like scale buildup or mechanical failures. At Holiday Ice, we emphasize the importance of routine maintenance, which includes cleaning the machine, checking water filters, and inspecting components for wear and tear. Proper maintenance ensures the ice quality remains high and prolongs the machine’s lifespan. Our customers often express surprise at the simplicity and cost-effectiveness of a well-maintained schedule, which can prevent costly repairs down the line.

If you’re not sure how to start a maintenance schedule, consider reaching out to an expert or checking our resources for detailed guidelines.

What advanced insights can optimize ice production?

Maximizing ice production efficiency involves more than just choosing the right machine. It’s about understanding the entire operational environment. Ensure the water source is clean and filtered, as impurities affect ice quality. Calibration based on your location’s altitude and temperature can enhance performance. Training staff on optimal operation techniques, such as loading and unloading, also plays a critical role. At Holiday Ice, we offer guidance and resources to help clients fine-tune their operations for peak efficiency, ultimately saving on costs and improving ice consistency.

Have you considered how minor adjustments in your process could lead to significant efficiency gains? It’s worth evaluating your current setup for potential improvements.

What are frequently asked questions about bulk ice makers?

Clients often ask about the ice maker’s capacity, efficiency, and environmental impact. Knowing the production capacity is crucial; our machines range from 2,500 to over 10,000 lbs per day, catering to varying needs. Efficiency concerns are addressed through the use of energy-efficient compressors and water-saving features like re-circulated water systems. Environmental impact is minimized with our focus on sustainability and reducing water consumption. Our machines are built with high-quality materials to ensure both durability and minimal environmental footprint.

Do you have specific questions about how a bulk ice maker can integrate into your business? Reach out for tailored advice that aligns with your operations.

Why is clear ice important for businesses?

Clear ice is essential not just for its aesthetic appeal but for its quality. It melts slower, preserving the flavor of beverages, which is vital in the food and beverage industry. For industrial applications, clear ice ensures purity and consistency, important in processes like chemical cooling or food preservation. At Holiday Ice, we utilize directional freezing in our machines to produce crystal-clear ice, meeting the high standards of our clients. This method freezes ice from one direction, pushing impurities out and ensuring clarity.

Have you thought about the impression clear ice makes on customers? It can be a subtle yet powerful way to elevate your brand’s perceived quality.

How does energy efficiency impact ice maker selection?

Energy efficiency in ice makers directly influences operational costs and environmental impact. Machines that use innovative compressors and water-saving systems reduce electricity bills and conserve water. Our Arctic-Temp® Ice Machines, for example, are designed to use less electricity than comparable models. Choosing an energy-efficient machine not only supports sustainability goals but also provides long-term savings, which is critical for businesses with high ice consumption. Clients typically appreciate the lower utility costs and the positive environmental impact.

Are you looking to improve your facility’s sustainability efforts? Energy-efficient equipment can be an excellent starting point.

What sets your customer service apart in the ice machine industry?

At Holiday Ice, we pride ourselves on personalized customer service. Unlike many others, we consider our clients part of the family, offering expert advice and support tailored to their specific needs. Our staff is trained to address unique client scenarios, whether setting up new systems or troubleshooting existing ones. Our emphasis on long-term relationships and client satisfaction is reflected in testimonials praising the reliability of our Arctic-Temp® machines and our responsive support team. We ensure our clients feel supported every step of the way, from purchase to maintenance.

Have you experienced exceptional customer service lately? It can dramatically change your perception of a company and its commitment to its customers.

Resources

- Department of Energy – The official website of the U.S. Department of Energy, providing information on energy efficiency and sustainability.

- Environmental Protection Agency – The EPA’s website offers resources on environmental standards and energy-saving initiatives.

- U.S. Department of Agriculture – The USDA provides information on food safety and quality, relevant to industrial ice production.

- National Institute of Standards and Technology – NIST offers resources on precision engineering and standards, essential in the production process of ice machines.

- United Nations – The UN’s website provides information on sustainable development goals, including energy efficiency and environmental impact.

What We Offer

OurIce Machines

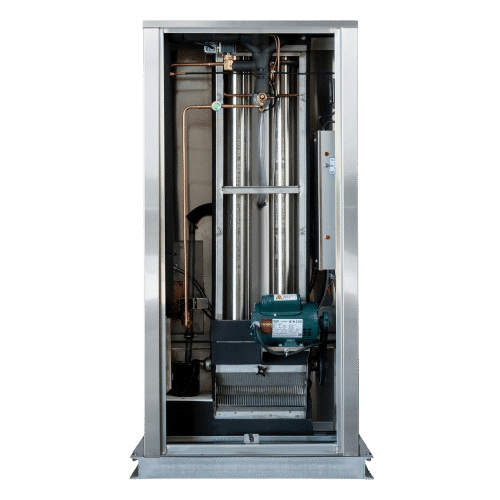

ARCTIC-TEMP® MODEL 500

- 2,500 lbs. of hard cracked ice in 24hrs. (907 Kg.)

- Highly efficient Copeland Compressor

- Double-Walled Vertical Tube Evaporators For Maximum Production

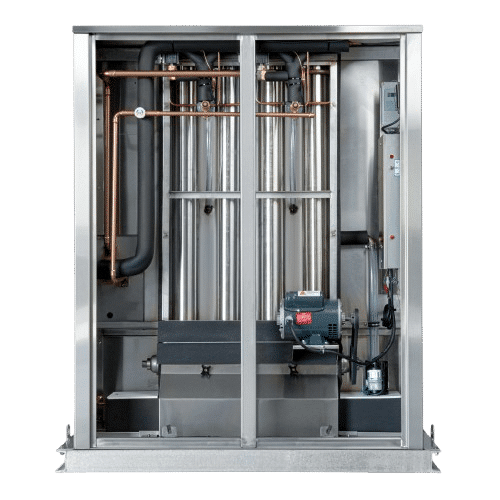

ARCTIC-TEMP® MODEL 750

- 4,500 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

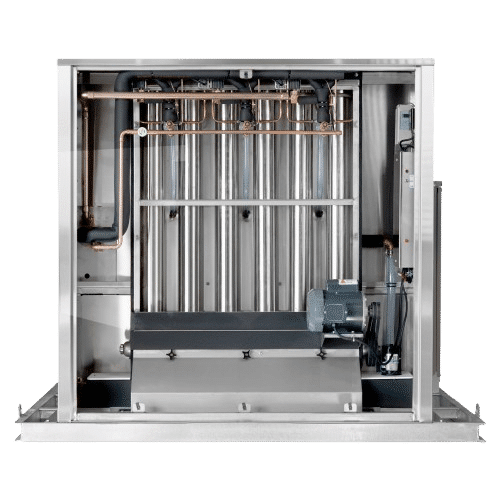

ARCTIC-TEMP® MODEL 1000

- 6,500 lbs. of hard cracked ice in 24 hrs. (2,948 Kg.)

- Highly efficient Copeland Discus Compressor

- Double-Walled Vertical Tube Evaporators

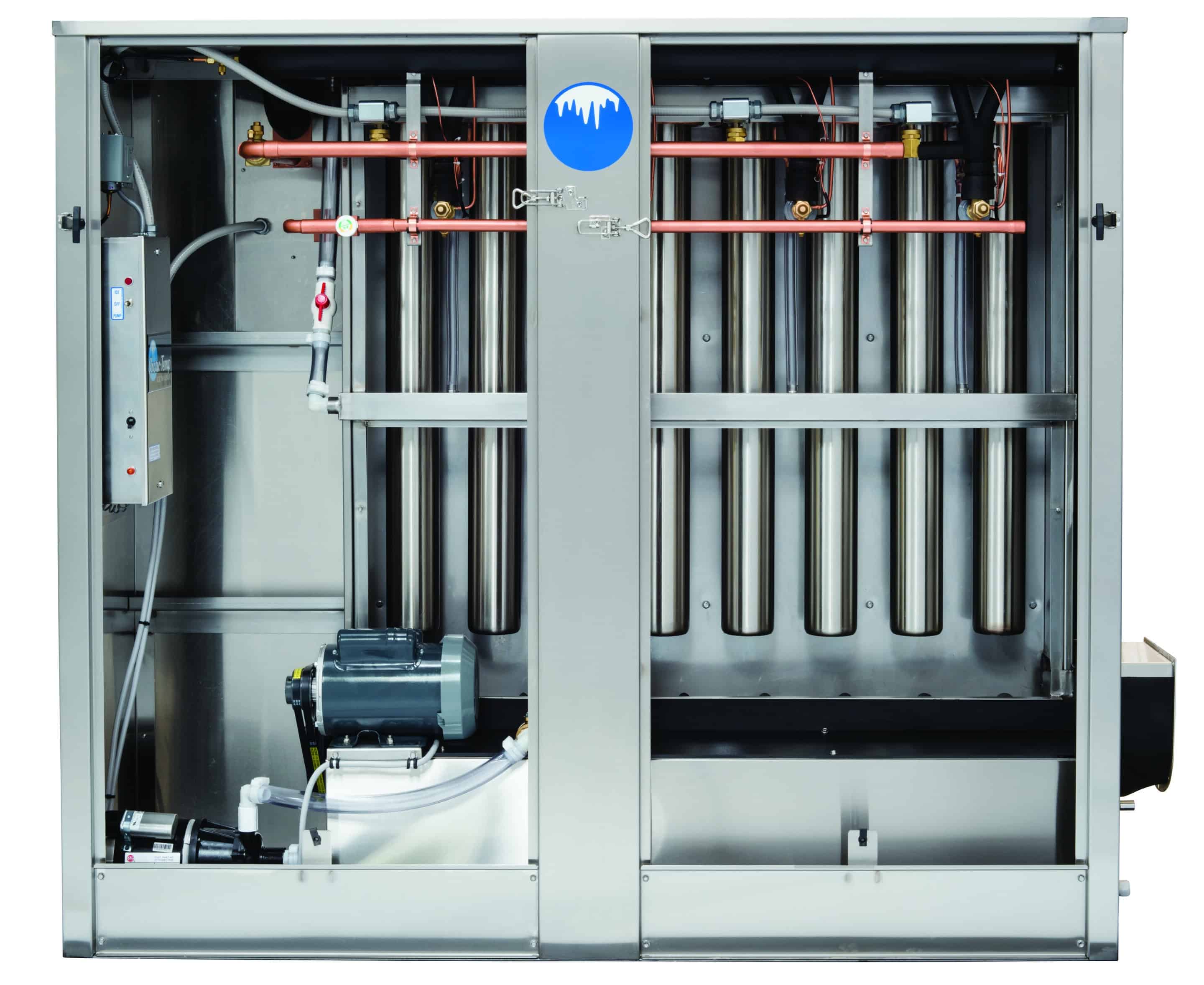

ARCTIC-TEMP® MODEL 1500

- 10,000 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

Ice Machine Manufacturing

ProductionProcess

- Our ice machines are built using high-quality Type-304 stainless steel, unlike other companies that use lower-grade alloys.

- Machines are hand-assembled and TIG welded for precision.

- Stainless steel evaporators are hand-formed and welded for durability.

- The ice-making section is fully assembled before being combined with the condenser and compressor.

- We use COPELAND compressors, known for their quality, industry-leading warranty, and widespread parts distribution.

- Our evaporators use a double-surface concave freezing technique with vertical tubes for faster, more efficient ice production and improved cooling.

- The freezing zone contains no moving parts, avoiding issues related to gears or motors.

- Standard, easily replaceable components are used, except for the evaporator, which simplifies maintenance after the warranty period.

- All machines are leak and vacuum tested, factory charged with refrigerant, and thoroughly calibrated for reliable performance from the start.

Years in Business

Ice Machines Sold

Repeated Customers

Countries Served

Global Network

CountriesWe Serve

North America

- • USA

- • Canada

- • Mexico

- • Bahamas

- • Anguilla

- • Cayman Islands

- • Jamaica

- • Dominican Republic

- • St. Lucia

Central America

- • Belize

- • Honduras

- • Nicaragua

- • Guatemala

- • El Salvador

South America

- • Guyana

- • Suriname

- • Ecuador

South America

- • Guyana

- • Suriname

- • Ecuador

Aruba

Iceland

Philippines

Oceania

- • American Samoa

- • Australia

Client Reviews

Testimonials

Discover firsthand experiences from our satisfied customers about their Arctic-Temp® ice machines.