Arctic-Temp® Ice Makers by Holiday Ice, Inc.

All Purpose Industrial Ice Machines From 2,500 to 10,000 lbs Per Day

Holiday Ice is a manufacturer of specialized, mid-range capacity commercial ice machines for industrial applications. For over 60 years, our commitment to personal service and outstanding quality has created a family of happy customers.

The Best Value

Our machines are efficient, economical, and made from the highest quality material and components, including top-of-the-line Copeland compressors.

Energy & Water Efficient

Our machines use re-circulated water, which saves you money on water costs. They also use less electricity than other models at the same capacity.

Realistically Rated

Our machines operate in Southern latitudes and are realistically rated for maximum performance during the scorching summer months when demand is greatest.

60+

years of experience

Who We Are

Holiday Ice,Quality You Can Count On.

Our Arctic-Temp® Ice Machines are legendary for providing years of reliable performance, even in the most grueling climates and conditions. Holiday Ice is a family-owned business, and we serve our customers with a personal touch.

Personalized Customer Service

Instead of some pre-recorded message, you’ll be greeted by a member of our friendly staff.

Top-Rated Copeland Compressors

No other manufacturer offers our combination of quality, longevity, price and service.

Best Ice Machine

Why Performance Matters in the Best Ice Machine

When considering the Best Ice Machine for industrial needs, performance is a pivotal factor. In my 20+ years working with these machines, I have learned that efficiency, capacity, and reliability are cornerstones of a high-performing ice machine. Our Arctic-Temp® Ice Machines excel in these areas by using Type-304 stainless steel and Copeland compressors, ensuring they meet the industry’s rigorous demands.

Performance is not just about speed and capacity; it’s about consistency over time. During the peak heat of summer, these machines must maintain their output without faltering. Rated for maximum performance, our machines cater to southern latitudes where the demand for ice surges when temperatures climb.

How Energy Efficiency Saves Costs in the Best Ice Machine

Energy efficiency is a critical consideration for anyone looking to invest in the Best Ice Machine. Having worked with energy-efficient designs, I’ve seen firsthand how they can significantly reduce operational costs. Our ice machines use re-circulated water, offering substantial savings in both electricity and water consumption compared to less efficient models.

This design not only supports sustainability but also contributes to long-term savings. The machines produce ice with minimized waste, which is a crucial aspect for industries focused on responsible resource use. With efficient energy use, our machines offer both environmental and economic benefits.

- Lower electricity bills

- Reduced water usage

- Minimal maintenance costs

The Importance of Durability in the Best Ice Machine

Durability is a hallmark of a Best Ice Machine. Our manufacturing process, which involves hand assembly and TIG welding, ensures that each machine withstands the rigors of frequent use. The use of robust materials like Type-304 stainless steel and hand-formed evaporators contribute to their long lifespan.

In the ice machine industry, durability is synonymous with reliability. I’ve worked with many clients who require continuous operation under challenging conditions, and our machines deliver that reliability. The use of quality Copeland compressors further enhances the machines’ longevity and performance.

For industries facing heavy daily use, investing in a durable machine reduces downtime and maintenance costs, resulting in a more dependable operation overall.

What Makes Great Customer Support for Ice Machines?

Effective customer support is essential when selecting the Best Ice Machine. A common question is how our personalized service supports clients worldwide. Our friendly and knowledgeable staff are pivotal in resolving any inquiry or issue swiftly. The result is a seamless experience that enhances trust in our product and service offerings.

Our customer support extends beyond troubleshooting; it includes guidance on machine selection, maintenance advice, and efficiency optimization tips. This comprehensive support framework is supported by positive client testimonials and experiences, reinforcing our commitment to client satisfaction.

- Contact our support team via phone or email

- Explain your issue or inquiry

- Receive tailored guidance or solutions

What Factors to Consider When Choosing the Best Ice Machine?

Finding the Best Ice Machine involves balancing capacity, efficiency, and design. To start, identify your daily ice requirements–our models offer capacities from 2,500 to over 10,000 lbs per day. Consider space constraints and installation needs as well, especially for industrial applications.

Efficiency should be another priority. Evaluate energy use and water consumption to ensure the machine meets both environmental and cost-saving criteria. Finally, assess the material quality and durability, knowing that longevity can drive down long-term costs and reduce operational disruptions.

The Importance of Quality Materials

When it comes to selecting the Best Commercial Ice Machine, the materials used in construction play a crucial role. At Holiday Ice, our machines are crafted using Type-304 stainless steel, known for its durability and corrosion resistance. This choice ensures that our ice machines not only stand the test of time but also maintain top performance levels. During my two decades at Holiday Ice, I’ve seen firsthand how investing in high-quality materials can reduce maintenance costs and improve long-term reliability.

The evaporators in our Arctic-Temp® Ice Machines are hand-formed and TIG welded, offering unparalleled precision and sturdiness. This meticulous attention to detail helps stabilize the performance across varying conditions, ensuring that our machines can handle even the most demanding industrial applications. For businesses in Southern latitudes where temperatures spike, this reliability during peak demand periods is a game-changer.

Advancements in Ice Machine Technology

Over the years, ice machine technology has evolved significantly. The Best Commercial Ice Machine today incorporates advanced features that optimize both energy and water usage. At Holiday Ice, we prioritize efficiency by utilizing COPELAND compressors, renowned for their reliability and energy-saving capabilities.

Our machines are designed to use re-circulated water, significantly reducing water wastage compared to traditional models. This not only lowers operational costs but also aligns with eco-friendly practices, an increasingly important consideration for businesses worldwide. The innovative design of our ice machines ensures they produce ice efficiently, even during peak summer months, which is essential for maintaining supply and meeting customer demands.

Our commitment to constant innovation means that we’re always looking for ways to improve the performance and efficiency of our products. By staying ahead of industry trends and incorporating cutting-edge technology, we ensure our machines remain at the forefront of the market.

Choosing the Right Ice Machine for Your Needs

With so many options available, selecting the Best Commercial Ice Machine can be daunting. Here’s a step-by-step guide to help you make an informed decision:

- Evaluate Your Capacity Needs: Determine the daily ice production capacity required for your operations. Our range from 2,500 to 10,000+ lbs per day caters to various industrial needs.

- Consider Energy Efficiency: Check for machines that offer energy-saving features, like the re-circulated water systems in our Arctic-Temp® models.

- Assess Durability Requirements: Look for machines made from high-quality materials such as Type-304 stainless steel to ensure longevity and resistance to corrosion.

- Verify Performance in High Temperatures: Ensure the machine is optimized for performance in high-temperature environments, facilitating reliable operation during peak periods.

- Evaluate Customer Support: Choose a manufacturer like Holiday Ice that provides exceptional customer service and support.

What Qualifies as a Best Commercial Ice Machine?

A Best Commercial Ice Machine is defined by its ability to deliver consistent, high-quality ice production while being energy-efficient and durable. At Holiday Ice, we believe that a combination of advanced technology, top-notch materials, and excellent customer support distinguishes our machines from the competition.

Incorporating COPELAND compressors ensures our machines deliver optimal performance, while the use of Type-304 stainless steel guarantees durability. Our focus on energy efficiency and water conservation not only reduces operating costs but also minimizes environmental impact, making our machines the preferred choice for many businesses.

The personalized service we offer further enhances the value of our ice machines. From initial inquiries to ongoing support, our team is dedicated to ensuring that each customer receives the best possible experience with their purchase.

Customer Experience and Testimonials

At Holiday Ice, we take great pride in the feedback we receive from our customers. Our commitment to quality and service has created a family of satisfied clients across North and South America, as well as in global markets like Iceland and Australia.

Our customers often highlight our machines’ reliability and efficiency, particularly during the hot summer months when demand is at its peak. The energy-saving features and robust construction of our ice machines have consistently exceeded expectations, leading to numerous repeat clients and referrals.

- Efficient, reliable ice production

- Durability even in harsh environments

- Outstanding customer service and support

- Cost-effective with eco-friendly features

These testimonials reinforce our position as a leader in the commercial ice machine industry, and we continually strive to uphold the standards of excellence that our customers have come to expect.

Choosing the Ideal Commercial Ice Maker

As an industry veteran with Holiday Ice, Inc., selecting the Best Commercial Ice Maker is crucial for ensuring efficiency and reliability. Over the years, I’ve seen that the quality of an ice maker hinges on several factors: material integrity, energy efficiency, and operational capacity.

Our Arctic-Temp® Ice Machines stand out due to their durable Type-304 stainless steel construction. This material resists corrosion, crucial for machines subjected to constant use. A Copeland compressor also enhances performance, allowing for the production of large quantities of ice even in Southern heat.

Energy efficiency is another critical aspect. Our machines utilize re-circulated water, minimizing waste and reducing electricity use, which is not only eco-friendly but cost-effective.

How to Maintain a Commercial Ice Maker

Maintaining your ice maker ensures longevity and optimal performance. Here’s a simple guide:

- Regularly clean the interior and exterior with a non-abrasive cleaner to prevent mineral build-up.

- Inspect water lines for leaks or blockages monthly.

- Check the condenser coils every quarter for dust and debris.

- Replace the water filter at least twice a year to ensure purity.

Keeping up with these steps will amplify the lifespan and reliability of your Best Commercial Ice Maker.

Choosing the Right Capacity

With capacities ranging from 2,500 to over 10,000 lbs per day, it’s essential to select the right unit for your needs. An ice maker that’s too small won’t meet demands, while an oversized unit could lead to unnecessary expenses.

At Holiday Ice, we often advise clients to estimate their daily ice requirements accurately. During peak seasons, a bit of excess capacity can be beneficial, especially for businesses in warmer climates or with fluctuating needs.

Understanding business patterns and choosing wisely can make a significant difference in operational costs and customer satisfaction.

The Best Commercial Ice Maker is one that seamlessly aligns with your specific operational needs, ensuring efficiency and reliability year-round.

What Makes an Ice Maker the Best?

The Best Commercial Ice Maker delivers consistently without compromising on efficiency or quality. The hallmark of such a machine lies in its ability to perform under varying conditions while maintaining energy and water efficiency.

Those machines employing top-quality components, like Copeland compressors, generally rank higher. They guarantee fewer breakdowns and a longer lifespan. Also, an effective ice maker should offer sufficient storage and ice-making speed, tailored to meet industrial demands.

- Durability through superior materials

- Energy efficiency with advanced technology

- Reliable performance in diverse climates

Our machines, with their robust design and customer-centric support, exemplify these traits, offering peace of mind and operational excellence.

Common Challenges in Operating Commercial Ice Makers

Despite the reliability of Arctic-Temp® Ice Machines, users occasionally face operational hurdles. Addressing these challenges promptly can prevent prolonged downtime and loss of productivity.

Common issues include mineral build-up, which can obstruct ice production and lead to machine inefficiency. Regular cleaning and maintenance are vital. Another challenge might be dealing with fluctuating temperatures. Our machines are engineered to withstand such variations, ensuring smooth operation regardless of external climates.

For any concerns, our support team at Holiday Ice is ready to assist, reflecting our commitment to unmatched customer service.

Why is performance crucial in selecting the best ice machine?

Performance is the cornerstone of a top-notch ice machine. It’s not just about how quickly or how much ice a machine can produce, but its consistent output over time, especially during peak seasons like the hot summer months. At Holiday Ice, we ensure our machines meet rigorous demands by crafting them with high-quality materials such as Type-304 stainless steel and efficient Copeland compressors. This approach ensures that when our machines are tested under high-demand conditions, they perform reliably. Imagine running a busy restaurant in a Southern U.S. state during July without worrying about whether you’ll have enough ice; this is the peace of mind we aim to provide with our products.

How does energy efficiency lead to cost savings in ice machines?

Energy efficiency in ice machines translates directly to cost savings, which is critical for businesses looking to minimize expenses. Our machines use re-circulated water systems, drastically cutting down on both water and electricity consumption. Over time, these savings add up, making a significant difference on operational costs. For instance, if you compare monthly utility costs of our machines with less efficient models, you’ll notice a notable reduction. This not only benefits your bottom line but also aligns with sustainable practices, supporting both economic and environmental goals.

Why is durability important in an ice machine?

Durability guarantees that your investment pays off over the long term. Machines that frequently break down or require repairs can disrupt business operations and add unexpected costs. At Holiday Ice, we emphasize using robust materials like Type-304 stainless steel and employing techniques such as TIG welding to ensure toughness in our machines. This durability is especially vital in industrial settings where machines are subject to continuous use. When you have an ice machine that’s built to last, you’re effectively securing a reliable source of ice without constant worry about maintenance.

What makes excellent customer support essential for ice machines?

Having access to stellar customer support can make all the difference when challenges arise. Great support means having a team ready to help with troubleshooting, maintenance advice, or even just answering questions about your machine. Our team at Holiday Ice is accessible and knowledgeable, providing peace of mind to clients who know they have someone to turn to. For example, imagine experiencing an issue with your ice machine at the peak of summer. With our prompt and effective support, you can resolve issues quickly, minimizing downtime and keeping your operations running smoothly.

What factors should be considered when choosing an ice machine?

The decision involves evaluating several factors, including capacity, energy efficiency, and the quality of materials. You want a machine that matches your specific ice demands, whether it’s 2,500 pounds per day or over 10,000. You should also consider space constraints and ensure that the machine is both energy and water-efficient to save on operational costs. Durability is another key aspect, which is why we pride ourselves on using high-quality materials. Think of it as choosing a long-term partner for your business–a reliable machine that bends to your needs without breaking.

How do quality materials impact the performance and longevity of an ice machine?

Quality materials like Type-304 stainless steel offer both durability and resistance to corrosion. They ensure that your ice machine can withstand the test of time, even in the most demanding environments. At Holiday Ice, we invest in high-grade materials and meticulous manufacturing processes, like hand-forming and TIG welding, to produce machines that are both robust and reliable. The impact is clear: less maintenance, fewer repairs, and a machine that continuously meets the performance standards you require, even during busy, high-temperature periods.

What recent advancements in ice machine technology should you be aware of?

Advancements in technology have led to more efficient and eco-friendly ice machines. At Holiday Ice, we incorporate features like COPELAND compressors, known for their reliability and energy-saving capabilities. Our use of re-circulated water systems is another innovation that reduces waste and operational costs. Staying up-to-date with such technologies ensures that your machine is not only saving money but also contributing positively to the environment. It’s fascinating to see how these advancements align economic benefits with global sustainability efforts.

How can you choose the right ice machine for your specific needs?

Choosing the right ice machine begins with understanding your daily ice requirements and the environment in which the machine will operate. For instance, if you’re running a seafood restaurant in a coastal city, you’ll need a machine that can handle humid conditions and high demand. Our Arctic-Temp® Ice Machines are specifically designed for such challenges, offering capacities ranging from 2,500 to over 10,000 lbs per day. Consider also energy efficiency and the quality of customer support, ensuring you have a partner ready to assist whenever needed.

What characteristics define the best commercial ice machine?

The best commercial ice machine combines high performance, efficiency, and durability. It should deliver consistent ice production while being energy-efficient and easy to maintain. At Holiday Ice, we’ve built our Arctic-Temp® machines with these principles in mind, incorporating advanced technology and high-quality materials to ensure lasting performance. These machines stand out not just for their reliability under demanding conditions but also for their cost-effectiveness over the long term. It’s about providing peace of mind and consistent results, keeping your business running smoothly.

How do customer testimonials inform your decision when choosing an ice machine?

Customer testimonials offer real-world insights into a product’s reliability and the company’s service quality. At Holiday Ice, we’re proud of the positive feedback from our clients who highlight the efficiency and durability of our machines. For instance, several clients have mentioned how our machines reliably served them during peak summer months when ice demand surged. Testimonials are a powerful tool–they provide prospective buyers with confidence and reassurance, knowing that others have had success with the product and service. Don’t just take our word for it; look at the experiences of those using the machines daily.

How do you maintain a commercial ice maker to ensure optimal performance?

Regular maintenance of your ice maker is crucial to its longevity and performance. This includes cleaning the interior and exterior regularly to prevent mineral build-up, which can impede efficiency. Monthly inspections of water lines for leaks or blockages and quarterly cleaning of condenser coils are also advisable. Additionally, replacing the water filter twice a year ensures that the ice remains pure. By following these simple steps, you’ll not only extend the life of your machine but also maintain its efficiency, ultimately saving on potential repair costs.

How do you determine the right capacity for an ice machine?

Determining the right capacity requires an understanding of your business’s specific needs. You don’t want a machine that’s too small, failing to meet demand, or too large, incurring unnecessary costs. We advise our clients to carefully estimate their daily ice requirements and consider potential spikes in demand, especially during peak seasons. For instance, a bar located in a tourist-heavy area might need extra capacity during the holidays. By matching the machine’s output with your precise demands, you’ll ensure efficiency and cost-effectiveness.

What makes an ice maker the best choice for commercial use?

The best ice maker for commercial use consistently delivers high-quality ice without compromising on efficiency. It should be made of durable materials to withstand constant use and varying conditions. At Holiday Ice, our machines include features like Copeland compressors, known for reliability and long lifespan, ensuring minimal breakdowns. Additionally, energy-efficient operations and sufficient storage are critical. A top-tier ice maker should integrate seamlessly into your operations, providing the reliability and performance you need without constant oversight–essentially, a robust partner in your business.

What are common challenges when operating commercial ice makers, and how can they be addressed?

Common challenges include mineral build-up, fluctuating temperature conditions, and occasional mechanical issues. Regular cleaning can prevent mineral deposits from affecting productivity, while machines designed to withstand temperature variations, like our Arctic-Temp® models, offer reliability. If mechanical problems occur, prompt attention and support are vital. At Holiday Ice, we provide extensive customer support to help resolve any issues quickly, demonstrating our commitment to ensuring your ice machines operate smoothly under all conditions. Addressing these challenges as they arise helps maintain operational efficiency and minimize downtime.

Resources

- U.S. Department of Energy – The official website for the U.S. Department of Energy, providing information on energy efficiency and cost-saving measures.

- U.S. Environmental Protection Agency – The official website for the U.S. EPA, offering resources on environmental sustainability and energy-efficient practices.

- U.S. Department of Agriculture – The official website for the U.S. Department of Agriculture, offering insights into sustainable agriculture practices and resource management.

- National Institute of Standards and Technology – The homepage of NIST, providing advanced technological standards and innovations for various industries including ice machine technology.

What We Offer

OurIce Machines

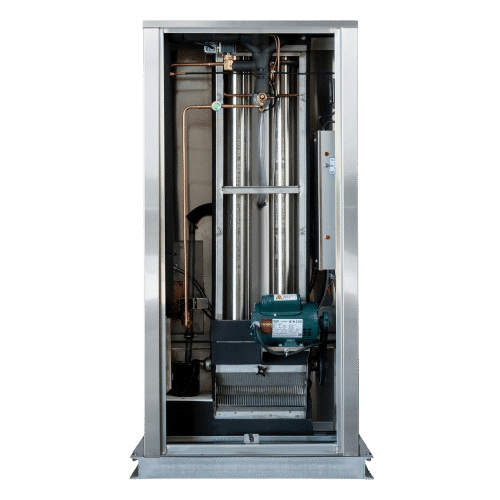

ARCTIC-TEMP® MODEL 500

- 2,500 lbs. of hard cracked ice in 24hrs. (907 Kg.)

- Highly efficient Copeland Compressor

- Double-Walled Vertical Tube Evaporators For Maximum Production

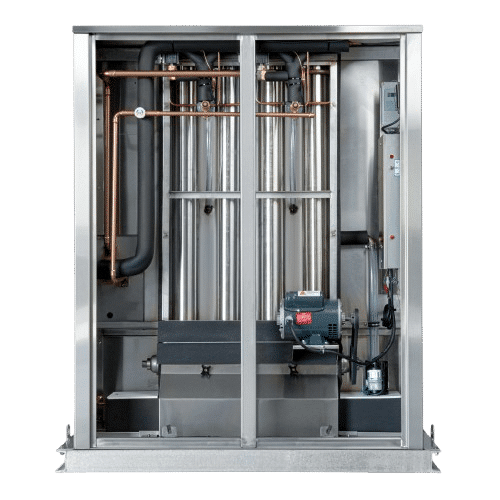

ARCTIC-TEMP® MODEL 750

- 4,500 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

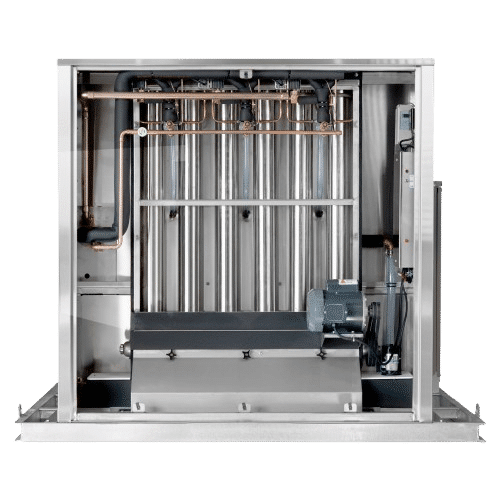

ARCTIC-TEMP® MODEL 1000

- 6,500 lbs. of hard cracked ice in 24 hrs. (2,948 Kg.)

- Highly efficient Copeland Discus Compressor

- Double-Walled Vertical Tube Evaporators

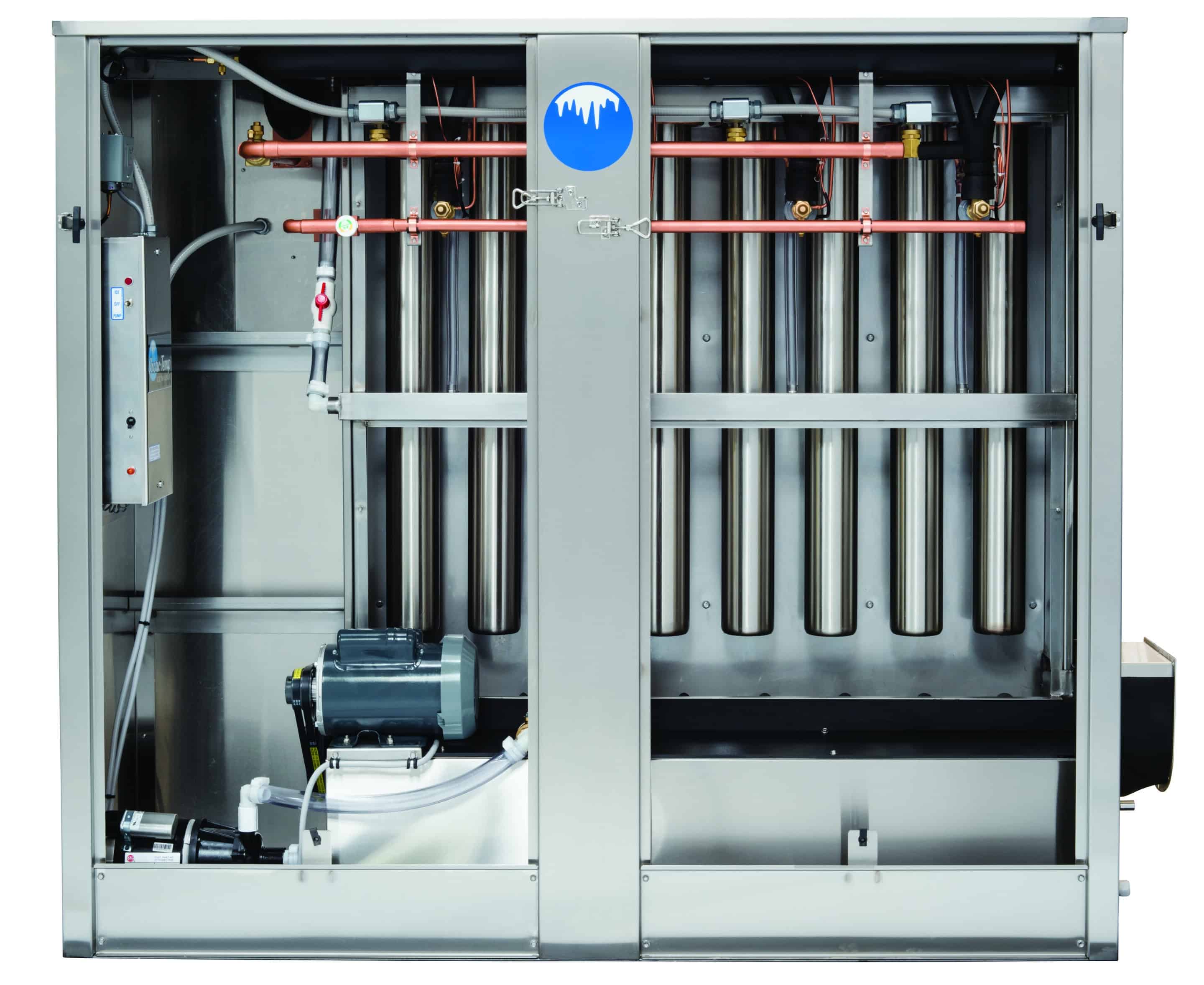

ARCTIC-TEMP® MODEL 1500

- 10,000 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

Ice Machine Manufacturing

ProductionProcess

- Our ice machines are built using high-quality Type-304 stainless steel, unlike other companies that use lower-grade alloys.

- Machines are hand-assembled and TIG welded for precision.

- Stainless steel evaporators are hand-formed and welded for durability.

- The ice-making section is fully assembled before being combined with the condenser and compressor.

- We use COPELAND compressors, known for their quality, industry-leading warranty, and widespread parts distribution.

- Our evaporators use a double-surface concave freezing technique with vertical tubes for faster, more efficient ice production and improved cooling.

- The freezing zone contains no moving parts, avoiding issues related to gears or motors.

- Standard, easily replaceable components are used, except for the evaporator, which simplifies maintenance after the warranty period.

- All machines are leak and vacuum tested, factory charged with refrigerant, and thoroughly calibrated for reliable performance from the start.

Years in Business

Ice Machines Sold

Repeated Customers

Countries Served

Global Network

CountriesWe Serve

North America

- • USA

- • Canada

- • Mexico

- • Bahamas

- • Anguilla

- • Cayman Islands

- • Jamaica

- • Dominican Republic

- • St. Lucia

Central America

- • Belize

- • Honduras

- • Nicaragua

- • Guatemala

- • El Salvador

South America

- • Guyana

- • Suriname

- • Ecuador

South America

- • Guyana

- • Suriname

- • Ecuador

Aruba

Iceland

Philippines

Oceania

- • American Samoa

- • Australia

Client Reviews

Testimonials

Discover firsthand experiences from our satisfied customers about their Arctic-Temp® ice machines.