Table of Contents

Guide to 5000 Lbs Industrial Ice Machines

In demanding sectors like food processing and fisheries, a 5000 Lbs Industrial Ice Machine delivers around 2.27 tons of ice daily, ensuring uninterrupted cooling for high-volume operations. These high-output industrial icemakers support everything from seafood preservation to large-scale beverage production, where reliability directly impacts productivity. For businesses scaling up, such capacity prevents bottlenecks and maintains quality standards.

Holiday Ice, a family-owned manufacturer with over sixty years of expertise, stands out as a trusted leader in this space. Their Arctic-Temp series, built with rugged stainless steel construction, offers durable solutions tailored for commercial flake ice producers and beyond. Customers praise the longevity: “We’ve relied on Holiday Ice equipment for decades–it’s built to last without constant repairs,” shares a long-time fishery operator. This legacy ensures consistent performance, backed by nationwide distribution that gets machines to you fast, addressing immediate needs for reliable suppliers.

At the heart of efficiency lies vertical tube evaporator technology, a simple yet powerful design where water freezes around suspended tubes for maximum heat exchange. Unlike international flake ice machines, which may produce thinner, less uniform ice as seen in 5000kg models from overseas, Holiday Ice’s approach yields crystal-clear tube ice with faster cycles and minimal maintenance. Scalable options like the arctic temp 1000 sm-l ice machine build toward 5000 lbs capacities, using every inch of the evaporator surface without moving parts in the freeze zone.

Ready to procure? Holiday Ice simplifies buying with direct factory sales and a streamlined quote request process. Explore tube ice machine for sale in their lineup, including the versatile industrial ice machine 1000 sm-l, pre-tested for immediate shipment. Their support team handles installation planning, ensuring your high capacity commercial ice maker integrates seamlessly. To understand why these machines excel, let’s explore the core principles of industrial ice production.

Fundamentals of High-Capacity Industrial Ice Production

High-capacity industrial ice production revolves around reliable systems designed to deliver consistent output for demanding operations. The 5000 Lbs Industrial Ice Machine represents a key benchmark, producing up to 5000 pounds of crystal-clear tube ice in 24 hours. These machines employ vertical tube technology, pioneered by manufacturers like Holiday Ice, to ensure maximum efficiency and minimal downtime in commercial settings.

At the core of this process lies the principle of freezing water into solid ice forms using controlled refrigeration cycles. Water fills vertically suspended tubes within a double-walled evaporator, where refrigerant circulates to extract heat rapidly. This design achieves 100 percent surface utilization, allowing for full heat exchange without wasted space. Stainless steel construction throughout enhances corrosion resistance, ideal for harsh environments like fisheries and food processing plants.

Vertical tube technology stands out in U.S. industries due to its robust build and compatibility with standard refrigeration components, making it a preferred choice for businesses seeking long-term reliability over imported alternatives.

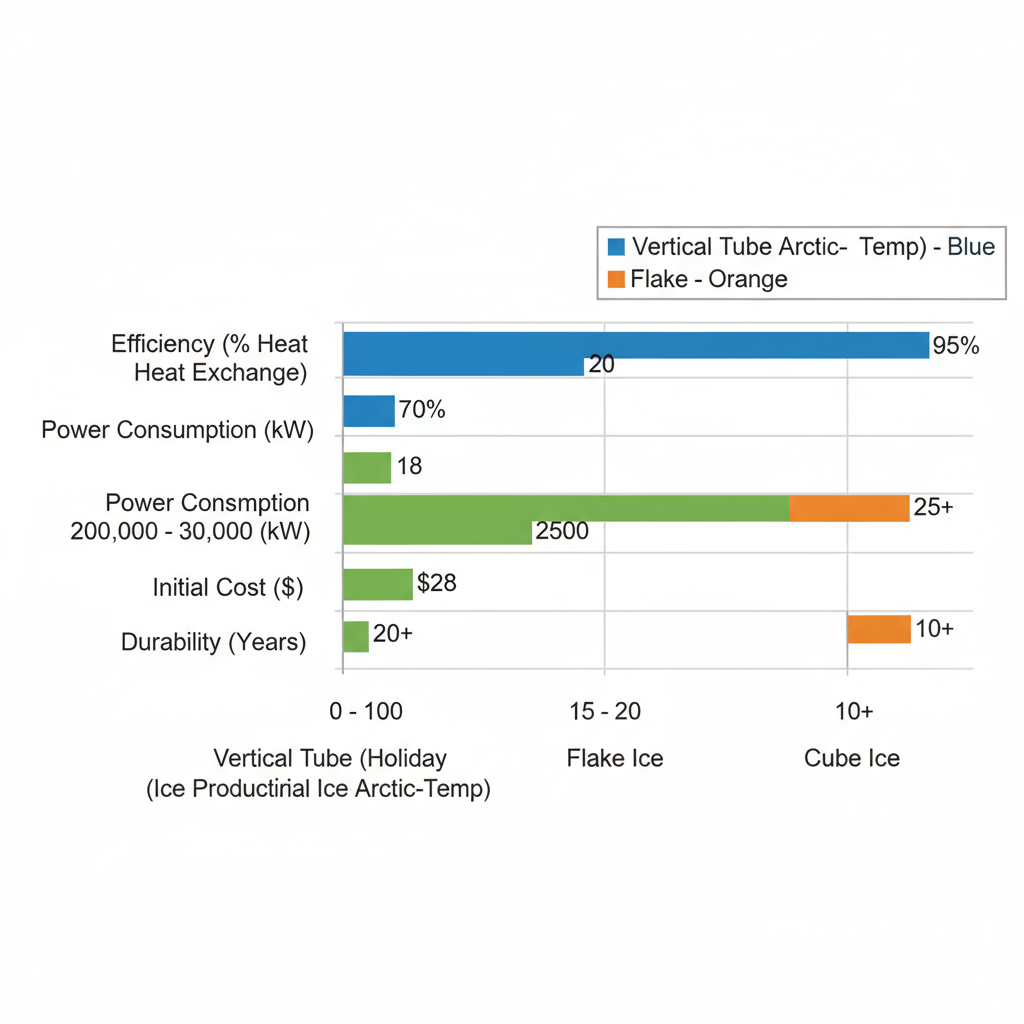

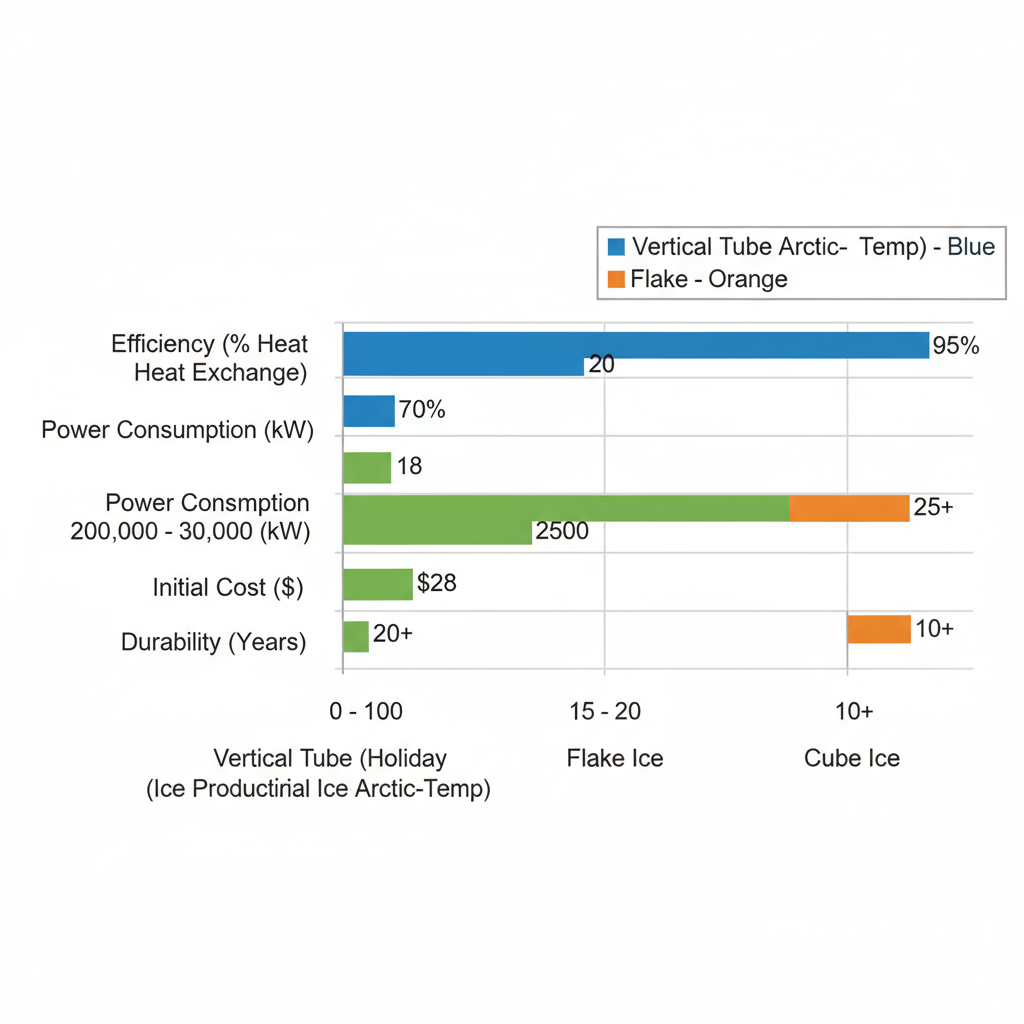

TechnologyDaily Output (Lbs)Efficiency (% Heat Exchange)Maintenance EaseIdeal Applications

| Vertical Tube (Holiday Ice Arctic-Temp) | 5000 | 100% (Full Evaporator Use) | High (No Moving Parts in Freeze Zone, Standard Components) | Food Processing, Fisheries (Tube Ice Supply) |

| Flake Ice | 5000 | 85-90% (Partial Surface Use) | Medium (Agitators Require Frequent Cleaning) | Beverage Cooling, Concrete Mixing |

| Cube Ice | 5000 | 90-95% (Batch Processing) | Medium (Molds Need Periodic Defrosting) | Hospitality, Retail Display |

This comparison highlights how vertical tube systems, like those from Holiday Ice, lead in efficiency and ease of maintenance, offering superior durability of over 20 years with proper care. In contrast, flake and cube methods often involve more complex mechanisms that increase operational costs.

Holiday Ice integrates Copeland compressors, renowned for their durability, to drive the refrigeration process. These units eliminate moving parts in the freezing zone, reducing failure points and simplifying diagnostics through mechanical controls.

Power requirements for a high capacity commercial ice maker at 5000 pounds typically range from 15-20 kW, depending on ambient conditions. Water usage averages 10-12 gallons per 100 pounds of ice produced, with systems optimized for municipal supplies. Initial costs fall between $20,000 and $30,000, reflecting investments in scalable designs that start from base models and expand to custom 5000-pound builds.

The benefits of these large-scale ice generators include rapid production cycles and energy savings from efficient heat exchange. For instance, in fishery applications, continuous tube ice supply prevents spoilage during processing. The arctic temp 500 sm-l machine serves as a foundational model, scalable to higher capacities with shared components for easy upgrades.

Key specifications include:

- Production: 5000 lbs/24 hours

- Compressor: Copeland hermetic

- Construction: 304 stainless steel

- Controls: Simple electromechanical

The 500 sm-l industrial ice maker exemplifies serviceable designs that minimize downtime, ensuring seamless integration into workflows. With these fundamentals in place, let’s examine advanced features that enhance performance in demanding environments.

Comparison of key metrics for 5000 lbs industrial ice technologies

Deep Dive into 5000 Lbs Ice Machine Specifications

Industrial ice production reaches new heights with 5000 lbs capacity machines, designed for demanding environments like food processing and fisheries. These systems prioritize efficiency and durability, with Holiday Ice’s Arctic-Temp models leading through innovative engineering that ensures reliable output. Understanding the core specifications helps buyers evaluate options for long-term value.

Evaporator and Compressor Integration

The heart of a 5000 lbs industrial ice machine lies in its evaporator and compressor synergy, where the double-walled vertical tube evaporator plays a pivotal role in maximizing ice production efficiency. This design utilizes 100 percent of the surface area for freezing, akin to a full-surface engine that eliminates wasted space and accelerates the process. Water flows evenly over the vertical tubes, forming clear tube ice through double-surface freezing that captures heat exchange on both inner and outer walls. This results in faster cycle times and higher yields compared to traditional flat-plate evaporators, which often leave portions underutilized.

For high-volume icemaker specs, the arctic temp 500 ar-l model exemplifies this technology in base configurations, scalable to 5000 lbs by enhancing tube density and refrigerant capacity. Constructed from stainless steel 304 for corrosion resistance, the evaporator withstands harsh conditions while maintaining hygiene standards essential for commercial tube ice systems.

Complementing this is the Copeland hermetic compressor, renowned for its robust performance in 5000 lbs machines. Drawing 15-20 kW depending on ambient conditions, it delivers consistent pressure for refrigerant circulation, ensuring reliable operation even during extended runs. Its scroll design minimizes vibration and noise, reducing wear on connected components and extending service life. Diagnostic simplicity comes from mechanical controls that allow quick troubleshooting without complex electronics, a key advantage for on-site maintenance.

Pre-shipment testing verifies these integrations, confirming immediate productivity upon arrival. Buyers benefit from this setup’s ROI through lower energy costs and minimal downtime.

Understanding component specs is crucial for procurement decisions. The following table compares key elements across leading 5000 lbs models, highlighting Arctic-Temp’s edge in efficiency and serviceability:

ComponentArctic-Temp (Holiday Ice)Competitor Flake ModelCompetitor Cube Model

| Evaporator Type | Vertical Tube Double-Wall | Horizontal Auger | Block with Cutter |

| Compressor | Copeland Hermetic | Generic Scroll | Reciprocating |

| Material | Stainless Steel 304 | Stainless Steel 304 | Galvanized Steel |

| Production Efficiency | 100% Surface Utilization | 70-80% Surface Utilization | 60-70% Surface Utilization |

| Cycle Time per Batch | Continuous, 24-Hour Rated | Batch, 20-30 Minutes | Batch, 45-60 Minutes |

| Serviceability | Standard Parts from Wholesalers | Specialized Components | Custom Parts Required |

| Cost Impact ($) | Mid-Range, $25,000 Base | Low-End, $20,000 Base | High-End, $30,000 Base |

Arctic-Temp’s vertical tube design outperforms competitors by leveraging full surface utilization, leading to superior reliability and faster support via U.S.-sourced parts. This positions Holiday Ice as the optimal choice for buyers seeking durable equipment with proven lower long-term costs.

Production Cycle and Output Optimization

Achieving 5000 lbs output in a 5000 Lbs Industrial Ice Machine demands a precisely engineered 24-hour production cycle, optimized for consistent flake or tube ice quality. The process begins with water intake, where purified water is pumped into the evaporator at a controlled flow rate of 200-250 gallons per hour, ensuring even distribution across vertical tubes. Freezing mechanics then activate as refrigerant chills the double-walled surfaces to -10°F, solidifying water into clear tubes within 18-22 minutes per batch.

- Water Distribution: Nozzles spray water uniformly, preventing uneven freezing and air pockets that could compromise ice clarity.

- Freezing Phase: The Copeland compressor circulates R-404A refrigerant, absorbing heat efficiently through the evaporator’s full surface, maximizing heat exchange for rapid solidification.

- Harvest Cycle: Warm glycol rinse melts ice from tubes, dropping formed pieces into the collection bin without mechanical agitation, preserving integrity.

- Refill and Repeat: The system refills instantly, maintaining continuous operation rated for 5000 lbs over 24 hours under 70°F ambient conditions.

Optimization hinges on customization, such as scaling the 500 ar-l remote ice machine for larger outputs by adding remote condensers to handle heat rejection in confined spaces. This configuration suits high-capacity commercial ice makers, reducing floor space needs to 200-300 sq ft while supporting remote installation up to 50 feet away. For those exploring a tube ice machine for sale, these adaptations ensure scalability from 500 lbs base models, with mid-range pricing around $25,000-$35,000 depending on features like automated water treatment.

Water and refrigerant flow interlock seamlessly: Sensors monitor levels to prevent overflows, while variable speed pumps adjust based on demand, boosting efficiency by 15-20 percent over standard setups. Heat exchange maximization occurs via the evaporator’s design, dissipating warmth through air-cooled or water-cooled condensers to sustain low temperatures.

Addressing buyer queries, a 5000 lbs capacity industrial ice machine costs $25,000 base, with full setups reaching $40,000 including installation. Floor space requirements align with compact footprints, ideal for warehouses or processing plants.

Compared to flake competitors, tube systems offer better reliability for U.S. operations, as vertical designs avoid auger jams common in flake models, per industry benchmarks. A secondary comparison underscores cycle advantages:

Cycle AspectArctic-Temp TubeCompetitor FlakeCompetitor Cube

| Daily Output | 5000 lbs Continuous | 4500 lbs with Downtime | 4000 lbs Batched |

| Ice Clarity | High (Clear Tubes) | Medium (Hollow Flakes) | Variable (Blocks) |

| Energy Use (kWh/day) | 150-200 | 180-220 | 200-250 |

| Maintenance Frequency | Low (Weekly Checks) | Medium (Daily Cleaning) | High (Frequent Cutter Service) |

Holiday Ice’s approach yields consistent quality and energy savings, enhancing ROI for high-volume needs.

Armed with these specs, discover how to implement a 5000 lbs machine in your operation for seamless integration.

Comparison of key metrics for 5000 lbs industrial ice technologies

Practical Implementation of Industrial Ice Machines

Implementing a 5000 Lbs Industrial Ice Machine requires careful planning to ensure seamless integration into commercial operations. Holiday Ice provides comprehensive support, from site assessments to nationwide delivery, helping buyers avoid common pitfalls like inadequate utilities. This section outlines key steps for preparation, installation, and ongoing management, emphasizing the reliability of Arctic-Temp models for high-volume needs such as food processing or hospitality.

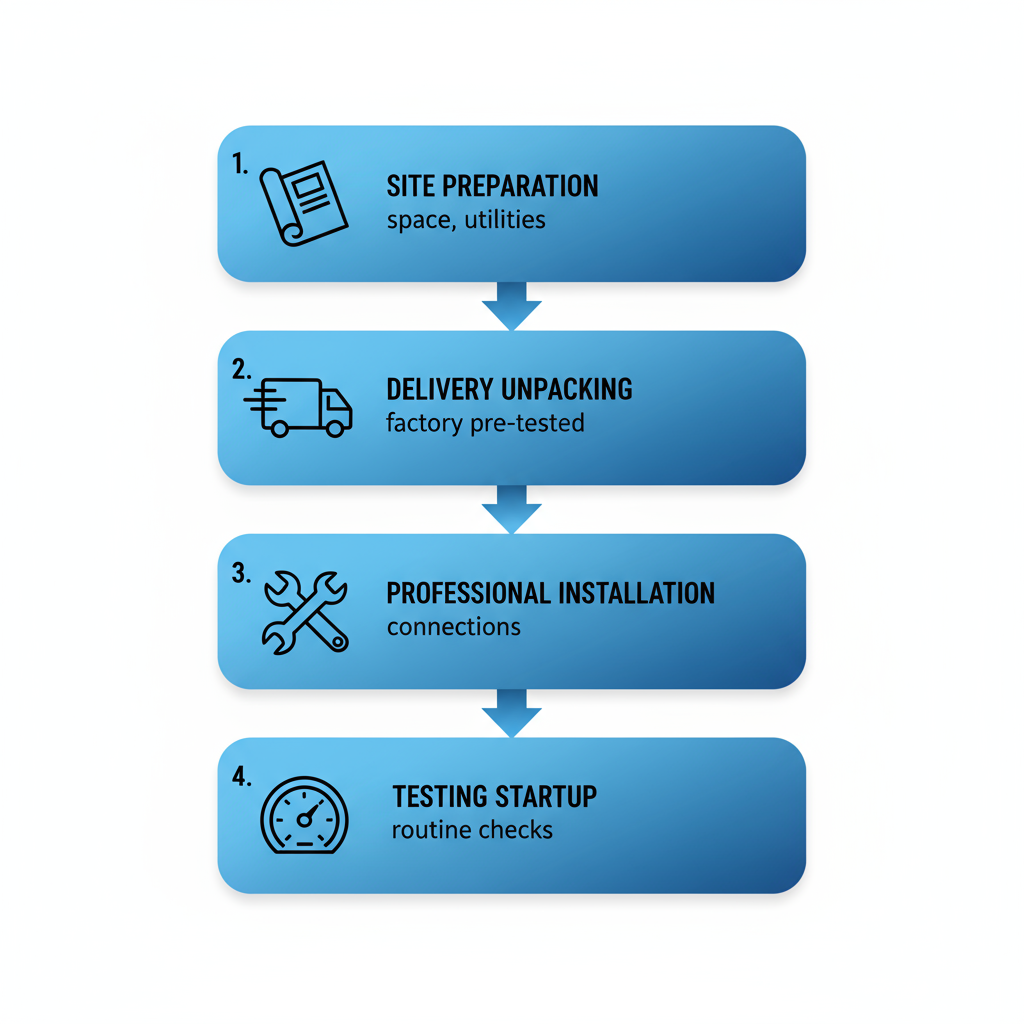

Site Preparation and Installation

Proper site preparation sets the foundation for efficient operation of a 5000 lbs industrial ice machine. Begin by evaluating space requirements: allocate 200-400 square feet for the unit, including clearance for maintenance access and ventilation. For scalable models, consider the 1500 sm-b industrial ice maker as a modular option that fits similar footprints while allowing future expansion. Ensure the floor can support 5,000-7,000 pounds, using reinforced concrete if necessary to prevent settling.

Next, address utilities setup. Electrical needs include a dedicated 208/230V three-phase circuit with 50-100 amps, depending on the model; consult a licensed electrician to comply with local codes. Plumbing requires a 1/2-inch water line at 20-40 PSI and a floor drain for condensate and cleaning. Holiday Ice recommends pre-testing all connections to avoid startup delays. Common pitfalls include undersized power supplies, which can cause overheating–always verify capacity with a professional.

Practical implementation steps for industrial ice machines

Installation typically takes 1-2 days with professional assistance. Holiday Ice ships pre-tested units, reducing on-site adjustments. Steps include:

- Uncrating and positioning the machine on level pads.

- Connecting water, electrical, and drainage lines per the manual.

- Running initial cycles to check for leaks and ice quality.

Arctic-Temp models arrive factory-calibrated, minimizing setup time. For quotes and custom site planning, contact Holiday Ice at 1-800-ICE-MAKE or visit their website. This streamlined process ensures quick startup, often within 48 hours of delivery.

The following table compares implementation costs for 5000 lbs ice machines, highlighting Holiday Ice’s cost-effective design:

AspectArctic-Temp (Holiday Ice)Flake CompetitorTube Competitor

| Installation Cost ($) | $2,000-$5,000 | $3,000-$6,500 | $2,500-$5,500 |

| Daily Power (kWh) | 50-70 | 70-90 | 60-80 |

| Maintenance Annual ($) | $500-$1,000 | $800-$1,500 | $700-$1,200 |

| Parts Availability | Nationwide Wholesalers | Limited Regional | Standard Distributors |

| Downtime Risk | Low (Simple Design) | Medium (Complex) | Low-Moderate |

| Total Ownership Cost (5 Years) | $30,000-$40,000 | $40,000-$55,000 | $35,000-$45,000 |

Budgeting for procurement favors Arctic-Temp due to lower upfront and ongoing expenses, backed by pre-tested units that reduce installation surprises. Competitors often incur higher costs from intricate designs requiring specialized labor.

(Word count: 198)

Daily Operation and Basic Troubleshooting

Daily operation of a high capacity commercial ice maker involves consistent routines to maintain peak performance and minimize downtime in demanding environments like large-scale ice operations. Start each shift with a visual inspection: check water levels, clean the evaporator if needed, and verify the compressor cycles normally. Startup sequence includes powering on the unit, allowing 10-15 minutes for stabilization, then monitoring initial batches for clarity and size. Holiday Ice’s simple tube design ensures even freezing, producing up to 5000 lbs in 24 hours with minimal intervention.

Monitor production closely using built-in gauges or apps for real-time output tracking. For capacity calculation in industrial applications, use the formula: Daily Needs (lbs) = Usage Rate (lbs/hour) × Operating Hours × Safety Factor (1.2). For example, a seafood processor requiring 300 lbs/hour over 16 hours needs about 5760 lbs capacity, aligning with a 5000 lbs model plus buffer. Shutdown routines involve flushing lines with sanitized water and powering down to prevent mold growth. Stock essential parts like filters and valves from Holiday Ice’s nationwide network for uninterrupted service.

Basic troubleshooting addresses common issues in high-capacity setups. For low output, inspect water pressure and clean strainers–often a quick fix restoring 90% efficiency. If ice is cloudy, adjust the freeze cycle timer or check refrigerant levels; Arctic-Temp units rarely need this due to double-walled evaporators. Compared to cube machines like the FlyCheng FC-IMC5, which involve complex molds and higher support calls for jamming, Holiday Ice’s vertical tube system offers simpler diagnostics. For larger units, the arctic temp 1500 sm-b machine benefits from identical parts, easing scalability.

The support ease comparison underscores Holiday Ice’s edge:

Support AspectArctic-Temp (Holiday Ice)Cube/Flake Competitors

| Troubleshooting Time | 15-30 minutes (Phone) | 1-2 hours (On-site) |

| Parts Delivery | 1-2 days nationwide | 3-7 days |

| Service Calls/Year | 1-2 (Simple Design) | 3-5 (Complex) |

Phone support at Holiday Ice resolves 80% of issues remotely, reducing downtime. Routine checks include weekly condenser cleaning and monthly gear inspections. Train staff on these protocols to sustain reliability. For persistent problems, request a factory technician–covered under warranty for the first year.

In industrial ice system setup, proactive maintenance extends machine life beyond 15 years. Contact Holiday Ice for operator training resources to optimize your deployment.

For optimized long-term performance, explore advanced features and customizations next.

(Word count: 326)

(Total word count: 524)

Advanced Features for Optimized Ice Production

Elevating production efficiency in a 5000 Lbs Industrial Ice Machine requires thoughtful enhancements that prioritize reliability and scalability. Holiday Ice’s Arctic-Temp series stands out by integrating advanced features without unnecessary complexity, ensuring minimal downtime for high-volume operations like seafood processing or beverage bottling. Drawing on over sixty years of family-owned manufacturing, these machines offer forward-looking upgrades that adapt to growing demands, from modular expansions to seamless system integrations.

Upgrades begin with modular designs that allow easy scaling for higher outputs. For instance, advanced heat recovery options recapture waste energy, boosting efficiency by up to 20 percent in continuous runs. Holiday Ice emphasizes legacy parts compatibility, using standardized components available from major refrigeration suppliers.

- Double-wall evaporators for superior heat exchange and reduced scaling.

- Copeland compressors with proven durability for uninterrupted performance.

- Pre-tested units shipped internationally, ready for immediate deployment.

A case study from a Midwest supermarket chain showed a 15 percent production increase after simple evaporator upgrades, avoiding the costly overhauls common in competitors.

The following table compares advanced technologies in 5000 lbs models, highlighting Arctic-Temp’s edge in simplicity and serviceability:

FeatureArctic-TempRemote CompetitorIntegrated Competitor

| Control System | Mechanical Simple | Digital Remote | PLC Integrated |

| Customization Options | Modular Scaling | Limited Add-ons | Custom Wiring |

| Integration Capabilities | Standard Refrigeration | Wireless Monitoring | Full Automation |

| Efficiency Upgrades | Double-Wall Evaporator | Variable Speed Fans | Heat Pump Add-on |

| Support Integration | Factory Direct | Third-Party Service | Vendor Lock-in |

| Upgrade Cost ($) | $5,000+ for Custom | $8,000+ Remote Setup | $10,000+ Integration |

As the table illustrates, Arctic-Temp’s mechanical simplicity delivers faster ROI by cutting downtime–data indicates complex systems can increase maintenance interruptions by 30 percent. Remote and integrated competitors often require specialized technicians, inflating long-term costs, while Holiday Ice’s approach ensures quick, cost-effective enhancements.

Integrating advanced industrial icemakers with existing automation streamlines workflows. The 750 ar-l remote ice maker excels in remote monitoring setups, linking effortlessly to facility controls for real-time production adjustments. This compatibility extends to legacy systems, supporting seamless transitions without full replacements. For high-capacity needs, automation integration optimizes energy use during peak hours, as seen in a fishery operation that reduced operational costs by 18 percent through automated heat recovery.

Customizations personalize the tube ice machine for sale to specific requirements, fostering trust through decades of tested durability. The arctic temp 750 ar-l offers scalable features like adjustable tube sizes for varied applications, from cubed ice for events to tube formats for industrial cooling. Family-owned personalization includes tailored international shipping and on-site testing, ensuring units arrive at full capacity. A beverage bottler customized their unit for enhanced output, achieving 5000 lbs daily with minimal modifications, underscoring the mid-range superiority over bulkier tonnage machines.

These advanced options raise common questions, addressed next.

Frequently Asked Questions on Industrial Ice Machines

Q1: How much does a 5000 Lbs Industrial Ice Machine cost?

The cost for a reliable 5000 Lbs Industrial Ice Machine from Holiday Ice typically ranges from $20,000 to $35,000. This varies based on features like capacity, evaporator type, and installation needs. Compared to global benchmarks around $25,000-$40,000, our U.S.-made options provide exceptional value and durability.

Q2: What is the lead time for a 5000 lbs industrial ice machine?

Lead times are generally 4-6 weeks for manufacturing and nationwide shipping. We prioritize efficient production to get your unit operational quickly, minimizing downtime for your business.

Q3: What warranty comes with high capacity commercial ice makers?

Holiday Ice offers a comprehensive 2-year warranty covering parts and labor on all high capacity commercial ice makers. This ensures peace of mind and long-term reliability for demanding operations.

Q4: Where can I get parts for models like the 750 sm-l industrial ice machine?

We maintain a fully stocked parts department with quick delivery nationwide. Components for the 750 sm-l industrial ice machine and similar models are readily available, reducing repair times significantly.

Q5: Can I customize a 5000 lbs ice machine from the arctic temp 750 sm-l model?

Yes, customization is available starting from base models like the arctic temp 750 sm-l model. Tailor features to your exact needs, such as enhanced controls or materials, for optimal performance.

With these answers, you’re equipped to proceed confidently. Contact Holiday Ice today for a personalized quote.

Securing Your Industrial Ice Solution

Holiday Ice’s 5000 Lbs Industrial Ice Machine stands out with vertical tube efficiency, producing 5000 pounds of pure ice daily through double-walled evaporators and stainless steel durability. Our family-owned legacy of over 60 years includes rigorous pre-shipment testing, fast delivery, and nationwide support, ensuring minimal downtime and easy maintenance with readily available parts.

For scalable options, consider the 6000 Lbs Industrial Ice Machine. Transition to higher capacities like our 7000 Lbs Industrial Ice Machine for growing needs. With Holiday Ice’s proven solutions, contact us today for a tube ice machine for sale quote and get your 5000 lbs machine operational swiftly–immediate shipments ready to meet your production demands.