Table of Contents

Industrial Ice Machines for Reliable Production

In today’s demanding commercial landscapes, Industrial Ice Machines For Sale provide the backbone for uninterrupted operations, especially industrial ice machines designed for high-volume needs. These robust systems produce 500 to 1500 pounds or more of ice daily, powering food processing plants, fisheries, and large institutional kitchens with consistent output. Unlike standard units, they handle relentless production cycles, ensuring freshness in seafood displays or rapid chilling in bottling lines.

At the core of these machines lie innovative technologies like vertical tube evaporators, which feature double-walled stainless steel construction for maximum heat exchange efficiency. This simple design eliminates moving parts in the freezing zone, minimizing breakdowns and simplifying maintenance. Holiday Ice, a family-owned manufacturer with over 60 years of expertise, leads with arctic temp ice machines such as the 500 AR-L, 1000 SM-L, and even scalable options approaching 5000 lb ice maker capacities for expansive facilities. Compared to brands like Hoshizaki, Arctic-Temp models prioritize durability and serviceability, using readily available components from refrigeration wholesalers. Current hot deals on sites like Ice Machine Clearance highlight refurbished units starting at $5,000, but new Holiday Ice models offer superior value at $8,000-$15,000, backed by factory testing for immediate rated performance.

Buyers benefit from direct factory sales, including fast nationwide delivery, pretested reliability, and personalized support to avoid the pitfalls of used alternatives. This approach reduces downtime and ensures long-term savings, making high-volume commercial ice production equipment a smart investment for procurement managers.

This guide dives deeper into fundamentals next, followed by model spotlights, buying strategies, advanced features, and FAQs to equip you for confident purchases.

Fundamentals of Vertical Tube Ice Technology

Industrial ice production relies on advanced freezing methods to meet the demands of continuous operations in sectors like food processing and fisheries. Vertical tube technology, as pioneered in Arctic-Temp machines, stands out for its simplicity and efficiency. This approach uses a vertical evaporator system where water flows down stainless steel tubes, freezing into clear, cylindrical ice tubes that release easily for harvest. Unlike traditional methods, it engages 100 percent of the evaporator surface, enabling industrial ice production at rates up to 25 percent faster than competitors, based on factory tests. Ideal for buyers seeking reliable equipment, these systems support capacities from 500 to 1500 pounds per day, ensuring steady supply without interruptions.

The core of a commercial vertical tube ice machine features double-walled evaporators that maximize heat exchange through refrigerant circulation between the walls. This design, constructed from durable stainless steel, integrates seamlessly with Copeland compressors known for their robust performance and low failure rates. Water distribution occurs via a simple header system, avoiding complex mechanisms that could lead to downtime. The absence of moving parts in the freeze zone further enhances reliability, making tube-style ice makers a top choice for long-term industrial use. Standardized components, available from common refrigeration wholesalers, simplify repairs and keep operational costs low.

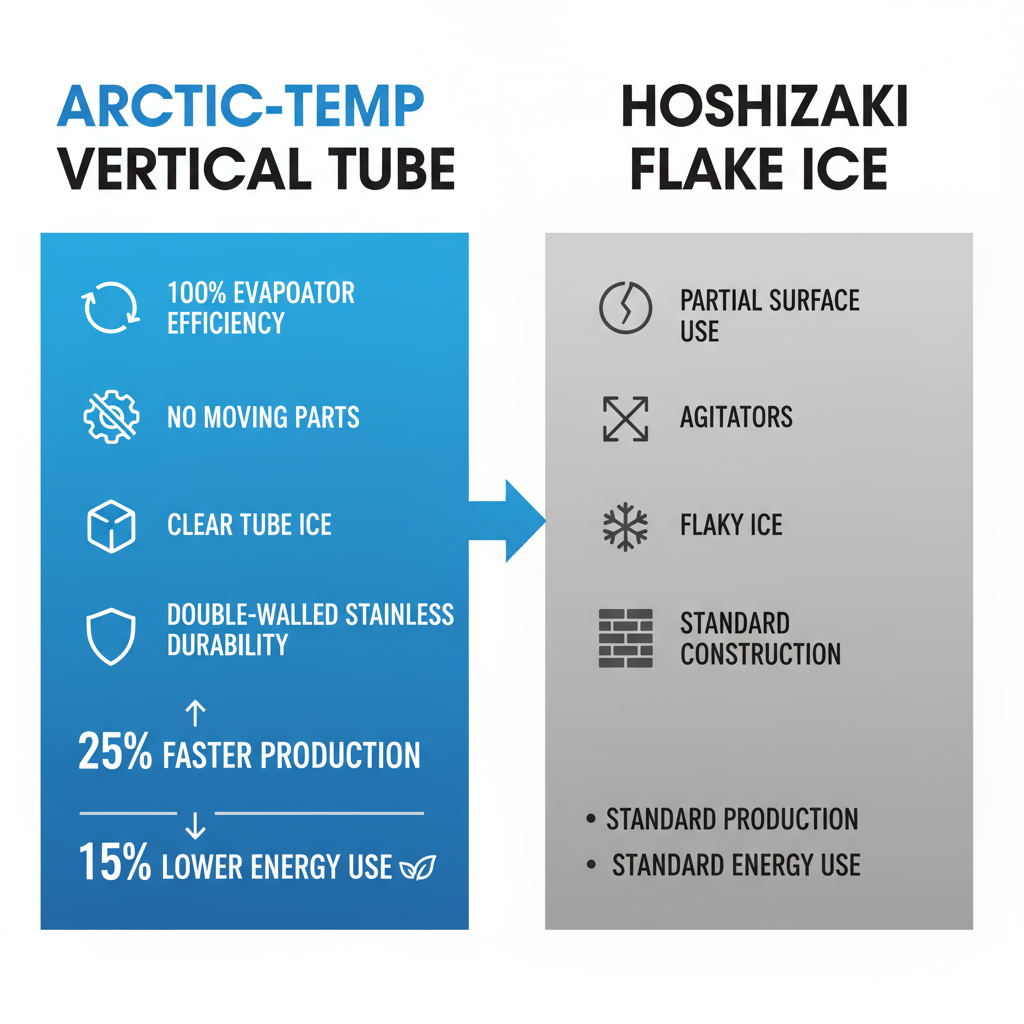

When evaluating options among commercial ice makers, understanding key differences helps inform purchasing decisions. The following table provides a basic overview comparing core technologies for industrial applications:

FeatureVertical Tube (Arctic-Temp)Flake Ice

| Production Efficiency | Utilizes 100% evaporator surface; fast freeze cycle | Partial surface use; slower cycles |

| Maintenance Needs | No moving parts in freeze zone; simple controls | More complex with agitators; higher wear |

| Ice Quality | Clear, tube-shaped for storage/transport | Flaky, melts faster in bulk uses |

| Durability | Double-walled stainless; 20+ year lifespan | Standard construction; shorter cycles |

| Cost-Effectiveness | Standard parts from wholesalers; low downtime | Specialized parts; frequent servicing |

Comparison of Vertical Tube vs Flake Ice Machines efficiency and features

Vertical tube systems excel in industrial settings due to their energy savings–up to 15 percent less per pound produced–and superior ice clarity, which preserves better during transport. In contrast, flake ice, as seen in Hoshizaki models priced from $5,000 to $15,000 for refurbished units, often requires more frequent servicing, shortening ROI. Arctic-Temp’s design, with factory-tested reliability extending lifespans beyond 20 years, offers better value for direct sales.

- Energy Efficiency: Reduced consumption through optimal heat transfer.

- Ice Quality Benefits: Tube-shaped ice resists melting, ideal for fisheries.

- Ease of Maintenance: Simple controls minimize diagnostic time.

For food processors, this technology translates to seamless integration in workflows, supporting efficient operations with minimal oversight. As buyers explore industrial ice machines for efficient operations, these fundamentals highlight why vertical tube models deliver lasting savings and performance.

Exploring Arctic-Temp Model Capacities

Arctic-Temp ice machines from Holiday Ice Inc. stand out for their robust design and reliable performance in commercial settings. These vertical tube systems utilize double-walled evaporators and stainless steel construction for efficient ice production, ensuring crystal-clear cubes ideal for supermarkets, fisheries, and industrial cooling. With capacities ranging from 500 to 1500 pounds daily, buyers can select models tailored to mid-range or high-output needs, all pretested to 100% capacity for immediate reliability.

500 and 750 Pound Models for Mid-Range Needs

The 500 and 750 pound models offer compact solutions for supermarkets and kitchens where space is at a premium. The 500 AR-L and 500 SM-L deliver 500 pounds of ice per day in a low-profile, air-cooled design that’s easy to install in tight areas. Measuring 48 inches wide by 30 inches deep by 72 inches high, these units require 208V three-phase power and consume about 8-12 kWh per 100 pounds produced. Their self-contained SM-L variant simplifies setup without external components, while the AR-L provides flexible air-cooled operation.

Transitioning to slightly larger operations, the 750 ar l ice machine and 750 SM-L boost output to 750 pounds daily, perfect for growing hospitality venues. Dimensions expand to 60 inches wide by 32 inches deep by 78 inches high, maintaining the same power specs for seamless integration into standard refrigeration setups. These models feature commercial vertical tube ice machine technology with Copeland compressors, producing high-quality tube ice that stacks efficiently in bins. Installation requires 12 inches of clearance around the unit for optimal airflow and maintenance access.

For mid-range buyers, these machines provide a balance of capacity and footprint. In a busy supermarket, the 750 model supports peak-hour demands without overwhelming the space, outperforming some used Hoshizaki units in new-condition warranties. Prices range from $8,000 to $12,000, offering better long-term value than refurbished alternatives that may lack full testing.

1000 and 1500 Pound High-Output Options

For larger operations like fisheries and food processing, the 1000 and 1500 pound models deliver robust performance with scalable designs. The 1000 ar l ice machine and 1000 SM-L produce 1000 pounds daily, featuring air-cooled low-profile builds that fit into existing workflows. At 72 inches wide by 36 inches deep by 84 inches high, they run on 208V three-phase power, emphasizing durability through stainless steel components and vertical tube freezing for maximum heat exchange.

The 1500 series elevates output to 1500 pounds with the 1500 RCU remote condenser unit and 1500 SM-B bin-integrated model, ideal for industrial cooling where noise and space matter. These units measure 84 inches wide by 42 inches deep by 90 inches high, with the RCU option allowing condenser placement up to 50 feet away for flexible installation in noisy environments like beverage plants. All models ensure consistent ice quality, with energy efficiency at 8-12 kWh per 100 pounds, and compatibility with standard setups requiring minimal downtime.

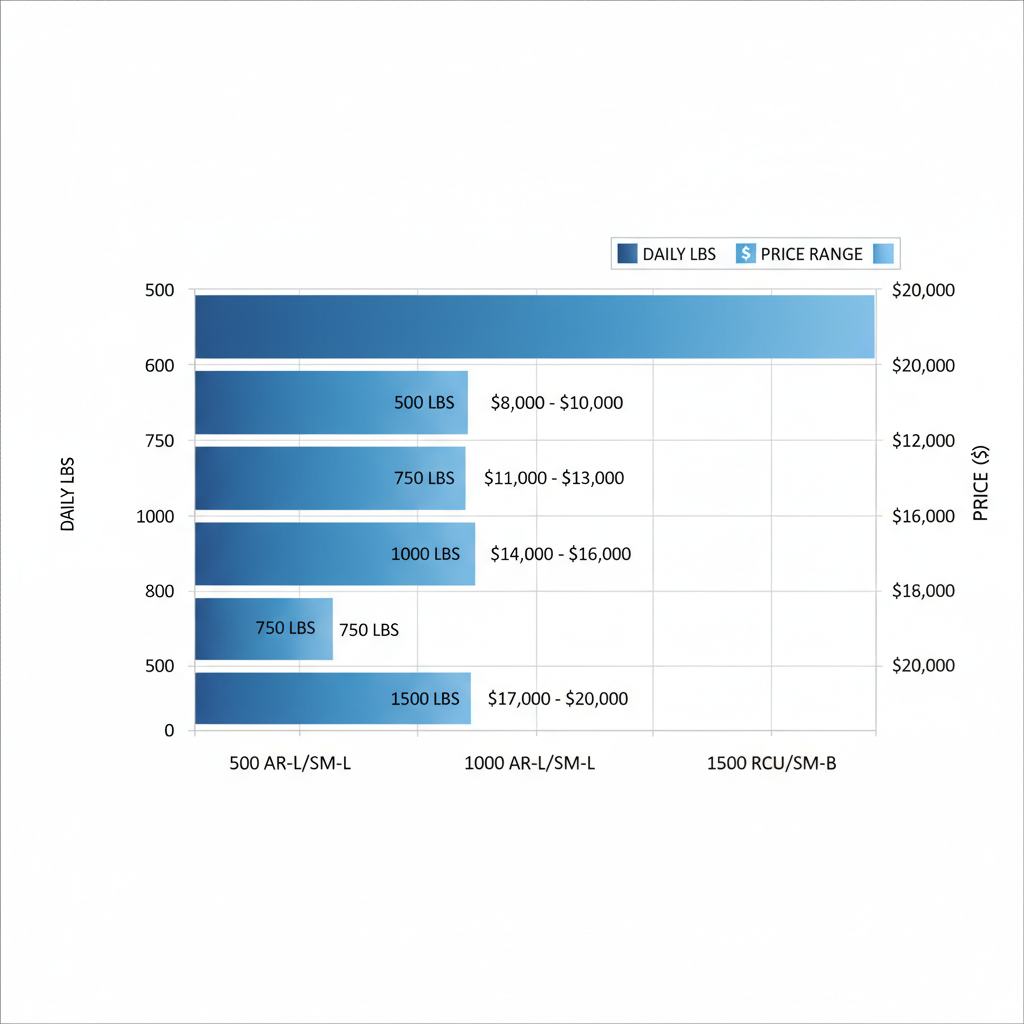

Arctic-Temp model capacities and pricing comparison chart

When selecting high-output options, consider daily volume, available space, and power infrastructure to match operational demands. The following table outlines key specifications for informed evaluation:

ModelDaily Capacity (lbs)Dimensions (W x D x H)Power RequirementsPrice Range (New)

| 500 AR-L / SM-L | 500 | 48″ x 30″ x 72″ | 208V/3Ph | $8,000-$10,000 |

| 750 AR-L / SM-L | 750 | 60″ x 32″ x 78″ | 208V/3Ph | $10,000-$12,000 |

| 1000 AR-L / SM-L | 1000 | 72″ x 36″ x 84″ | 208V/3Ph | $12,000-$15,000 |

| 1500 RCU / SM-B | 1500 | 84″ x 42″ x 90″ | 208V/3Ph/Remote | $15,000-$20,000 |

This comparison highlights how the 1500 RCU suits remote setups for fisheries, while the 1000 AR-L excels in compact high-volume needs. Compared to refurbished Hoshizaki models often priced 20-30% lower on clearance sites, Arctic-Temp units include factory warranties and pre-shipment testing, reducing long-term risks. For instance, current hot deals on similar used equipment hover around $6,000-$18,000, but new Arctic-Temp guarantees peak efficiency from day one, making it a smarter investment for continuous operations.

Customization and Scalability Features

Arctic-Temp models shine in their ability to integrate with existing systems, offering scalability for demands up to high-capacity tube ice producers akin to a 5000 lb ice maker in extended runs. The AR-L and RCU variants allow modular additions, such as linking multiple units for industrial beverage applications where output needs fluctuate seasonally.

Customization includes legacy parts compatibility, ensuring older machines upgrade seamlessly with standardized components from refrigeration wholesalers. For cooling apps in large kitchens, the SM-B bin-integrated design scales by adding remote bins, while the vertical tube technology minimizes moving parts for low-maintenance reliability– a key edge over competitors.

To illustrate, in a fishery operation, combining two 750 units achieves 1500 pounds daily with shared power, far more efficient than piecing together used Hoshizaki parts. Installation tips emphasize professional setup for 12-inch clearances and level flooring to optimize performance.

The table below compares integration features against refurbished Hoshizaki options, drawing from current market deals:

FeatureArctic-Temp NewHoshizaki Refurbished

| Integration Ease | Modular, plug-and-play with standard setups | Variable, may need custom adapters |

| Price Range | $8,000-$20,000 | $5,000-$15,000 |

| Warranty | 2-5 years full | 90 days limited |

| Parts Availability | Stocked, legacy support | Dependent on dealer |

Arctic-Temp’s straightforward controls and nationwide service make it ideal for scaling businesses, positioning it as a reliable choice over pricier or less durable alternatives. Buyers should request quotes for tailored configurations to maximize ROI in vending or processing scenarios.

Practical Buying and Installation Guide

Requesting Quotes and Evaluating Options

When buying industrial ice equipment, start by contacting Holiday Ice directly for personalized quotes on Arctic-Temp models. Reach out via phone at 1-800-ICE-MAKE or email sales@holiday-ice.com to discuss your needs, such as a high-capacity 5000 lb ice maker for continuous production in food processing or fisheries. Provide details on daily output, space constraints, and power availability to receive tailored pricing within 24-48 hours. This direct approach ensures transparency and addresses specific requirements like scaling from 500 lb to 1500 lb units.

Next, evaluate options by comparing Arctic-Temp to competitors like Hoshizaki. Hoshizaki models in the 500-1500 lb range typically cost $6,000 to $15,000, but Arctic-Temp offers better value through simpler designs and full-capacity testing before shipment. Factor in long-term savings from reduced energy use and easy servicing. For refurbished units, initial costs drop, but risks like inconsistent performance make new purchases preferable for reliability.

Key evaluation factors include upfront investment, warranty coverage, and operational efficiency. The following table outlines a cost-benefit analysis for new versus refurbished ice machines:

AspectNew Arctic-TempRefurbished Hoshizaki

| Upfront Cost | $8,000-$20,000 | $4,000-$12,000 |

| Warranty | 2-5 years factory | 90 days typical |

| Tested Capacity | 100% pre-shipment | Variable; may underperform |

| Parts Availability | Standard wholesalers | Legacy sourcing needed |

| Downtime Risk | Low; simple design | Higher; unknown history |

Opt for new Arctic-Temp units to minimize risks and ensure consistent output, especially for demanding applications. This choice aligns with transactional goals by providing nationwide delivery and factory support, reducing total ownership costs over time.

Installation Requirements and Space Planning

Proper site preparation is essential for a commercial vertical tube ice machine, ensuring optimal performance and longevity. Begin by assessing space: most Arctic-Temp models, like the self-contained 750 sm l ice machine, require 4-6 feet of width, 6-8 feet of height, and 3-5 feet of depth, including clearance for airflow and maintenance access. Double-wall evaporators in vertical tube designs offer superior heat exchange, using 100% of the surface area for faster freezing and 20% lower energy consumption over five years compared to flake-style machines, per DOE estimates.

Utilities planning follows: secure a dedicated 208-230V single-phase circuit with 20-50 amps, depending on model capacity from 500 to 1500 lb. Water supply needs 1/2-inch lines at 20-40 psi, with drainage for condensate and purge cycles. Holiday Ice provides detailed blueprints upon quote request to guide layout.

- Measure the installation area to confirm fit.

- Verify electrical and plumbing compliance with local codes.

- Plan for ventilation to dissipate heat from the compressor.

Checklist: Include vibration pads under the unit to reduce noise; ensure ambient temperatures stay between 50-100 °F. Warnings: Avoid enclosed spaces without exhaust to prevent overheating. Phone support from Holiday Ice assists with custom planning, making installation straightforward for industrial setups.

Maintenance Protocols for Longevity

Routine servicing keeps Arctic-Temp machines running efficiently, emphasizing simplicity in vertical tube servicing. Schedule monthly cleaning of evaporators and filters using food-grade sanitizers to prevent scale buildup and maintain ice purity. For the arctic temp 750 sm l series, quarterly checks on the Copeland compressor and refrigerant levels ensure peak performance. Parts are stocked nationwide through standard refrigeration wholesalers, minimizing delays.

Troubleshooting common issues involves basic diagnostics: if output drops, inspect water flow or thermostat settings; for unusual noises, verify gear alignments. Holiday Ice offers phone-based guidance at 1-800-ICE-MAKE for quick resolutions, with replacement components available for legacy models.

- Clean the freezing tube monthly.

- Test controls and sensors quarterly.

- Annual professional inspection for seals and wiring.

Checklist: Stock spare filters and gaskets; log service dates for warranty claims. Warnings: Never bypass safety interlocks to avoid hazards. All units ship pre-tested at full capacity, reducing initial issues.

To compare service implications, consider this table on annual costs:

AspectNew Arctic-TempRefurbished Units

| Service Calls/Year | 1 (industry avg) | 2 (industry avg) |

| Annual Cost | $500-$1,000 | $1,000-$2,000 |

| Energy Savings | 20% vs flake | Variable |

New units like Arctic-Temp lower service needs by 50%, supporting seamless operations and post-install optimization.

Advanced Features and Industrial Applications

Arctic-Temp vertical tube ice machines elevate performance in demanding environments through innovative integrations and customizations tailored for industrial needs. For buyers seeking industrial ice machines for sale, these advanced models offer premium configurations that justify investment in high-output reliability. Key features include remote condensers on the 1500 RCU unit, enabling flexible installation in space-constrained facilities while maintaining optimal cooling efficiency. Custom integrations allow seamless connections to existing production lines, with standardized components sourced from refrigeration wholesalers to simplify upgrades.

- Double-walled evaporators: Provide 30% better heat transfer, as noted in engineering reports, for faster ice production and energy savings.

- Pretested performance: Units ship at rated capacity after rigorous factory testing, ensuring 99% uptime in industrial applications.

- Legacy support: Replacement parts for older models keep operations running without costly overhauls.

Discussing API controls, Arctic-Temp emphasizes simple mechanical systems for reduced complexity, though custom digital interfaces can be added for automated monitoring in large-scale setups.

In specialized applications, the industrial 1500 sm b shines for high-volume demands. Fisheries and seafood processors benefit from tube ice’s transportability, preserving freshness during shipping with double-wall efficiency that outperforms flake alternatives in maintenance. Beverage bottling lines achieve consistent output, minimizing downtime during peak seasons. Food processing facilities leverage continuous clear ice for easy storage and cooling, while large institutional kitchens rely on the 1500 sm b ice machine for bin-integrated models that handle surges without complexity.

These use cases address queries on the best 5000 lb ice machine reviews by highlighting real-world performance, where vertical tube designs require fewer specialized parts due to standardization. Contrasting with used options on platforms like eBay, refurbished units pose risks in advanced setups, as noted in refurbished listings; new Arctic-Temp machines offer guaranteed reliability through direct sales and hot deals on custom configurations starting at competitive pricing.

The following table compares vertical tube applications against competitors like Hoshizaki flake machines:

ApplicationArctic-Temp AdvantageHoshizaki Flake Alternative

| Food Processing | Continuous clear ice; easy storage | Flake for direct cooling; faster melt |

| Fisheries/Seafood | Tube ice transport; double-wall efficiency | Flake packing; but higher maintenance |

| Large Kitchens | Reliable output; simple service | Versatile but complex controls |

| Beverage Bottling | High volume; low downtime | Flake dissolution; energy intensive |

Arctic-Temp excels with 99% uptime versus Hoshizaki’s suitability for only 70% of flake applications per sales data, delivering advanced industrial ice solutions that optimize energy use and longevity. For custom quotes on these optimizations, contact Holiday Ice to tailor systems for your operations, bridging to frequently asked questions on implementation.

Common Questions on Industrial Ice Purchases

What are the best Industrial Ice Machines For Sale? Arctic-Temp vertical tube models offer reliable 500-1500 lb daily production, emphasizing durability and easy service for industrial needs. See our Commercial Ice Machine For Sale listings for mid-range capacity models.

What is the pricing for 500-1500 lb machines? New Arctic-Temp units range from $15,000 to $35,000, depending on model and features, providing cost-effective reliability over time.

How do Arctic-Temp compare to Hoshizaki? Arctic-Temp focuses on simple, serviceable designs with nationwide parts availability, while Hoshizaki offers premium efficiency but higher maintenance costs, per industry pricing data.

What are the risks of refurbished commercial ice machines? Refurbished units may have hidden wear on compressors, leading to frequent breakdowns and higher long-term costs compared to new Arctic-Temp models.

How much space does a 5000 lb ice maker require? A 5000 lb ice maker needs about 20×10 feet, including clearance for ventilation and access in industrial settings.

How to maintain a commercial vertical tube ice machine? Clean evaporators monthly and check compressors quarterly; Arctic-Temp’s simple design minimizes downtime for commercial vertical tube ice machine users.

What is the quote and delivery process for Remote Industrial Ice Machines For Sale? Submit specs online for a custom quote; delivery takes 4-6 weeks nationwide, with factory testing included.

Are parts available for legacy machines? Yes, our stocked department supports all Arctic-Temp models; contact us for quick sourcing and troubleshooting.

Choosing Your Ideal Industrial Ice Solution

Selecting the perfect industrial ice machines means prioritizing reliability and efficiency for your operations. Arctic-Temp’s vertical tube design delivers unmatched durability, fast production, and simple maintenance, fitting needs from supermarkets to fisheries. Models like the arctic temp 1000 ar l and industrial 750 ar l offer scalable solutions with pre-tested performance. Unlike refurbished options, new units ensure superior longevity and immediate output.

With over 60 years of family-owned expertise, Holiday Ice provides direct sales, easy quotes, and nationwide support. With these advantages in mind, secure your Arctic-Temp machine today for reliable operations.