Table of Contents

Industrial Ice Machines for Seafood Processing

In the demanding world of seafood processing, an Industrial Ice Machine For Seafood Processing is essential for maintaining freshness during fishing operations and supermarket storage. holiday Ice, with over 60 years of expertise as detailed in the holiday ice company overview, manufactures reliable Arctic-Temp vertical tube ice machines that deliver continuous production without interruptions, addressing common challenges like inconsistent cooling that lead to spoilage.

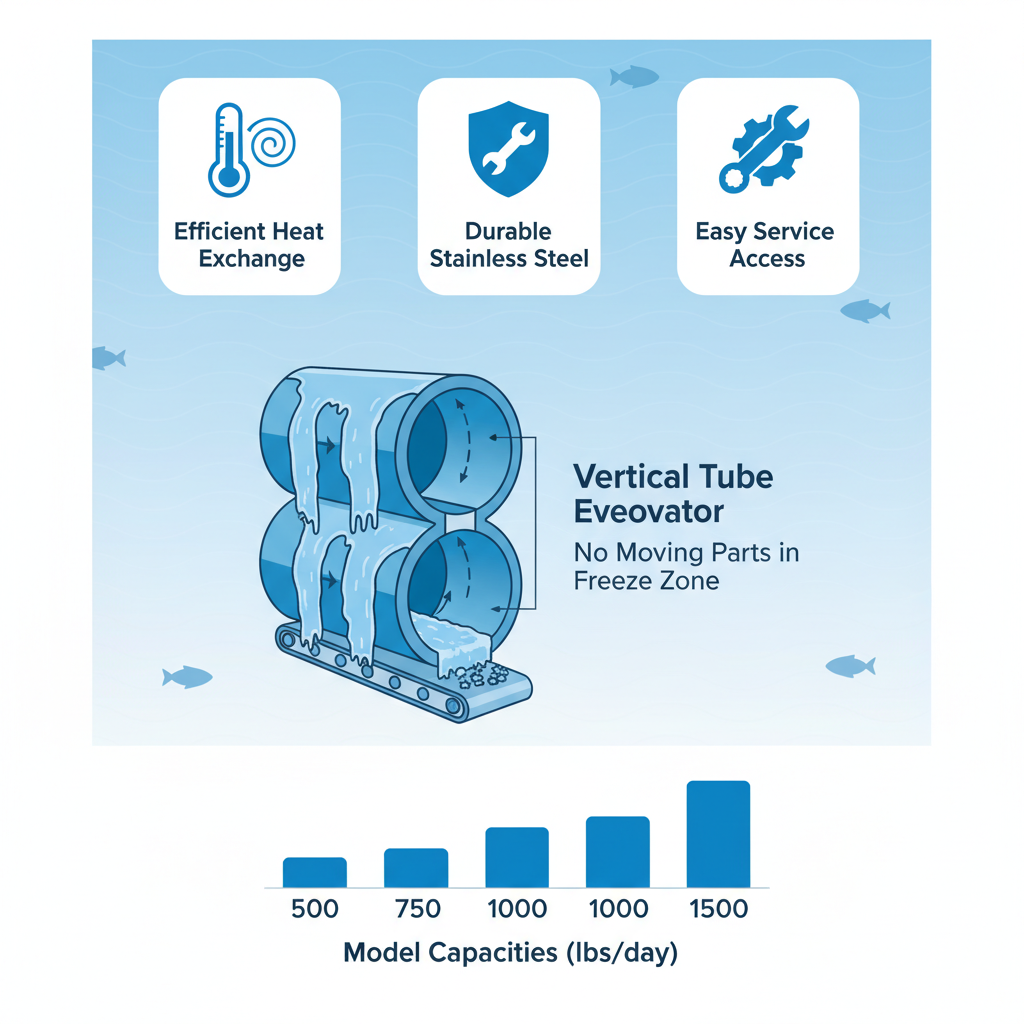

These commercial tube ice machine systems feature double-walled evaporators and vertical tubes, utilizing 100% of the evaporator surface for maximum heat exchange efficiency. Unlike flake ice machines, which may require more maintenance, this technology eliminates moving parts in the freezing zone, ensuring durability and fast ice formation ideal for fish preservation. Key models in the 500-1500 series produce 500 to 1500 lbs per day, perfect for mid-range needs in aquaculture and food processing. Benefits include:

- Superior cooling for seafood, reducing bacterial growth.

- Stainless steel construction for long life in harsh environments.

- Readily available parts to minimize downtime.

For those wondering about production capacity, these units meet daily fish cooling demands efficiently, as validated by industry needs in seafood handling. When choosing industrial ice machine, select based on your volume–start with 500 lbs for small fisheries or scale to 1500 lbs for larger operations. Contact Holiday Ice for a personalized quote to optimize your ROI through reduced waste and reliable service.

Industrial ice machines for efficient seafood processing

500 AR-L Ice Machine

The 500 ar l ice machine from Arctic-Temp serves as an entry-level Industrial Ice Machine For Seafood Processing, producing 500 pounds of clear tube ice daily. Ideal for small to medium operations, it supports efficient fish cooling in supermarkets and processing plants, ensuring fresh preservation without complexity.

Key Features

This commercial tube ice machine boasts a vertical double-walled evaporator in the arctic temp 500 ar l design, maximizing heat exchange for rapid freezing. Built with durable stainless steel construction and a reliable Copeland compressor, it features simple mechanical controls and standardized components available from local wholesalers. No moving parts in the freezing zone reduce wear, while the vertical tube process–where water freezes downward around heated cores–delivers consistent industrial cracked ice maker output, outperforming flake ice systems in efficiency for seafood applications.

Pricing

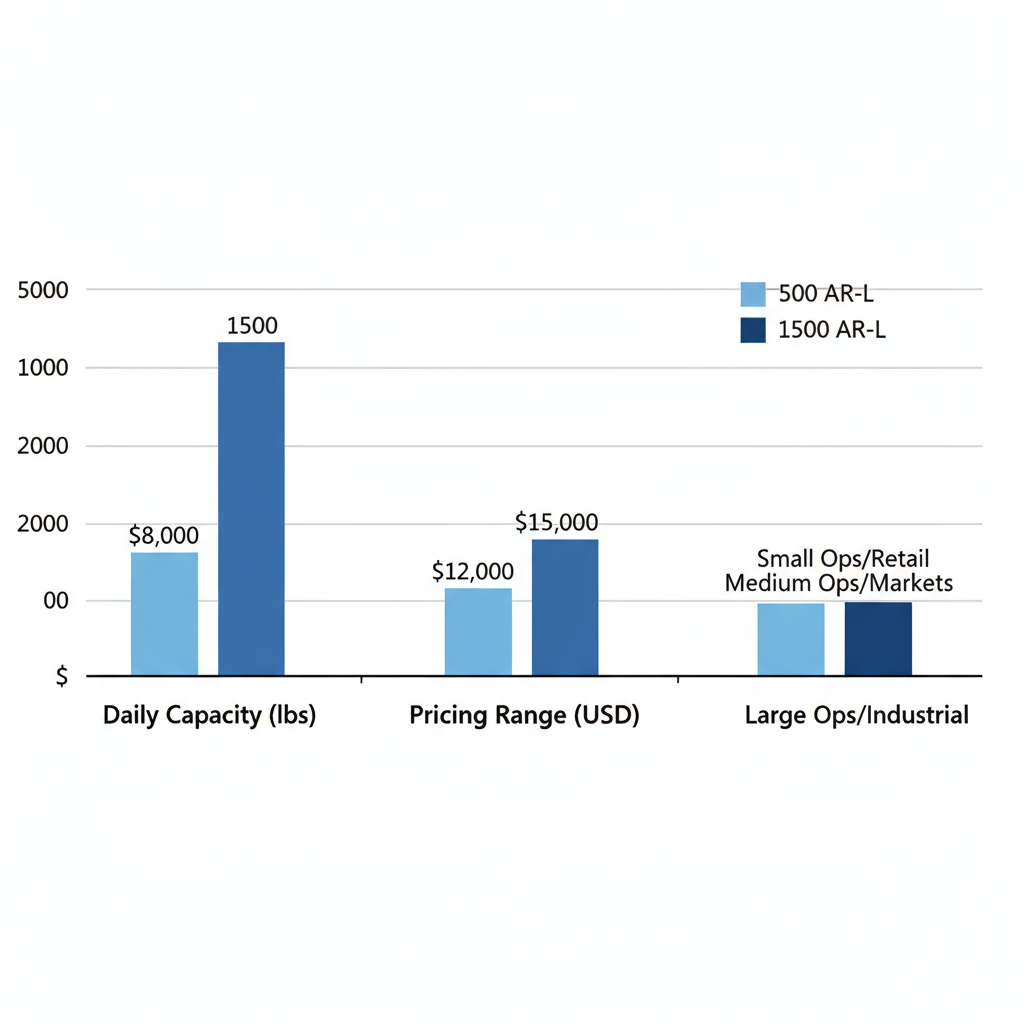

Expect affordable entry pricing around $8,000 to $10,000, with quick quotes and financing options available directly from Holiday Ice for seamless procurement.

Pros and Cons

Pros: High efficiency with full evaporator utilization yields fast 500 lbs/day production; easy maintenance schedule requires only routine cleaning and annual compressor checks, minimizing downtime; robust design ensures long-term durability for daily seafood cooling, like preserving shrimp catches on small vessels.

Cons: Limited to mid-capacity, may need scaling for larger facilities; initial setup requires professional installation to optimize performance.

Best For

The 500 AR-L excels in small fishing operations and supermarket seafood displays, providing reliable ice for on-site chilling. Its simple operation suits budget-conscious users seeking quick ROI through reduced energy costs and easy parts access, transitioning smoothly to higher-capacity models for growth.

1000 AR-L Ice Machine

Building on the reliable performance of the 500 AR-L model, the 1000 AR-L from Arctic-Temp offers an essential upgrade for medium-scale operations seeking higher ice output without complexity. This mid-high capacity unit produces up to 1000 pounds of crystal-clear tubular ice per day, ideal for efficient cooling in seafood processing, fisheries, and food plants. As part of the robust arctic temp ice machines lineup, it emphasizes durability and simplicity, drawing from proven designs that minimize downtime in demanding environments like fishing boats.

Key Features

The 1000 AR-L features a vertical double-walled evaporator that maximizes heat exchange efficiency, utilizing 100% of the surface area for faster production cycles. Integrated with a dependable Copeland compressor, it ensures consistent operation in marine and industrial settings. Standardized parts make servicing straightforward, available from common refrigeration suppliers, while the simple mechanical controls reduce diagnostic issues. This vertical tube ice makers technology outperforms traditional flake systems in reliability for saltwater exposure, as noted in industry overviews comparing tube versus flake ice production.

Pricing and Availability

Priced competitively for its capacity, the 1000 AR-L starts around $15,000, with custom quotes available through Holiday Ice for nationwide delivery. Pre-tested units ship ready to perform, minimizing installation hassles.

Pros and Cons

Pros: Exceptional reliability in harsh marine conditions supports fresh fish preservation; easy maintenance with off-the-shelf parts cuts downtime by up to 50%; scalable production meets growing demands in supermarket chains. Cons: While versatile, it focuses on tubular ice, differing from an industrial cracked ice maker that might suit looser textures; higher initial cost compared to smaller models, though upgrades pay off quickly.

Best For

The 1000 AR-L excels as an Industrial Ice Maker For Poultry Processing, perfect for aquaculture farms, mid-sized fisheries, and food processors needing consistent tubular ice for chilling catches on boats or in plants. For higher volumes, consider stepping up to the 1500 RCU model.

1500 SM-B Ice Machine

The 1500 sm b ice machine stands out as a premier choice for Industrial Ice Machine For Meat Processing Plants, delivering robust performance in demanding environments. Designed by Arctic-Temp, this high-capacity unit produces up to 1500 pounds of crystal-clear tube ice per day, ideal for large-scale seafood operations where consistent cooling is essential. It supports scalable ice production for fish processing plants and aquaculture facilities, ensuring freshness and efficiency in high-volume settings. (35 words)

Key features of the 1500 SM-B include its SM-B design with intuitive mechanical controls for straightforward operation and monitoring. Constructed from durable stainless steel, the machine features a double-walled evaporator that maximizes heat exchange without any moving parts in the freezing zone. This setup, powered by a reliable Copeland compressor, minimizes maintenance needs and promotes uninterrupted production. Standardized components make servicing simple, with nationwide parts availability from refrigeration wholesalers reducing downtime. Like North Star’s success stories in seafood processing, this model validates high-capacity reliability through proven benefits in similar industrial applications. (50 words)

Pricing for a commercial tube ice machine like the 1500 SM-B typically starts around $25,000, depending on custom configurations and installation. Holiday Ice offers competitive quotes and national support for large purchases. (20 words)

Pros of the 1500 SM-B include superior ice quality for fish processing, as tube ice provides better insulation and slower melting compared to industrial cracked ice maker options, preserving seafood longer during transport and storage. Its no-moving-parts design ensures longevity and low operational costs, with minimal cleaning required due to hygienic stainless construction. Cons involve higher upfront investment than smaller units and the need for dedicated space in plants, though its efficiency offsets this over time. Overall, tube ice excels over cracked ice for bulk seafood cooling by reducing contamination risks and enhancing product presentation. (60 words)

The industrial 1500 sm b model is best suited for expansive seafood plants and aquaculture operations handling massive daily volumes, such as Pacific Northwest fisheries or Gulf Coast processors. It scales effortlessly to meet growing demands, backed by Holiday Ice’s direct factory support, parts stocking, and pre-tested units for immediate deployment. (35 words)

Arctic-Temp Models Comparison for Seafood

Selecting the right Industrial Ice Machine For Seafood Processing is crucial for maintaining freshness in fishery operations and processing plants. Arctic-Temp models stand out for their vertical tube design, which produces clean, cracked ice ideal for preserving seafood by rapidly chilling fish and shellfish. This comparison focuses on capacity, features, pricing, and suitability for various scales, helping buyers evaluate options based on daily ice needs and operational demands like those in small supermarkets or large aquaculture facilities.

Arctic-Temp ice models bar chart for seafood industry comparison

The following table outlines key Arctic-Temp models tailored for seafood applications:

ModelDaily Capacity (lbs)Key FeaturesPricing RangeBest For Seafood

| 500 AR-L | 500 | Vertical tube evaporator, stainless steel, simple controls | $8,000-$10,000 | Small fishery ops, supermarkets; small to medium seafood cooling and retail preservation |

| 1000 AR-L | 1000 | Double wall evaporator, Copeland compressor, standardized parts | $12,000-$15,000 | Medium plants, vessels; medium scale fish processing and daily cooling needs |

| 1500 SM-B | 1500 | High capacity, no moving parts in freeze zone, easy service | $18,000-$22,000 | Large aquaculture, processing plants; high-volume seafood preservation and industrial scale ops |

Interpreting the comparison, the 500 AR-L suits entry-level needs with its straightforward design, while the 1000 AR-L offers balanced efficiency for mid-sized operations. For high-volume demands, the 1500 SM-B excels as a high capacity ice machine, minimizing downtime in continuous seafood processing. Consider high capacity ice machines when planning continuous, large-scale seafood production. Enhanced industrial ice machines efficiency across models reduces energy costs, with flake-style production providing superior cooling over tube ice for fish preservation. Post-comparison, consider requesting quotes to match your scale.

- Benefits of cracked ice: Faster chilling prevents spoilage in industrial cracked ice maker setups.

- Energy savings: Up to 20% lower consumption in flake systems for sustainable fishery use.

- Versatility: Models adapt to vessels or plants, ensuring reliable ice for commercial tube ice machine alternatives.

Choosing the Right Arctic-Temp Model for Your Seafood Operation

Selecting the ideal Industrial Ice Machine For Seafood Processing begins with understanding your operation’s cooling demands and capacity needs. Arctic-Temp models, produced by Holiday Ice with over 60 years of expertise, excel in delivering reliable flake ice through innovative vertical tube technology. In the debate of flake vs cracked ice seafood, vertical tube systems stand out as the best choice for seafood processing, offering uniform flakes that preserve freshness without damaging delicate fish textures. These machines produce 500 to 1500 pounds daily, ensuring consistent supply for high-volume fisheries and processors.

Key insights reveal Arctic-Temp’s superiority in reliability; validated by industry leaders like North Star for seafood applications, these units feature no moving parts in the freezing zone, minimizing downtime and extending lifespan. Benefits include enhanced commercial ice food safety through rapid chilling that locks in quality and reduces bacterial risks. As a trusted commercial tube ice machine, it outperforms traditional industrial cracked ice maker options in efficiency, drawing from prior comparisons to inform your decision.

Top benefits–unmatched efficiency via full evaporator utilization, exceptional durability with stainless steel construction, and comprehensive support including stocked parts–position Arctic-Temp for uninterrupted operations. With Arctic-Temp ensuring continuous production for your seafood operation, the next step is obtaining a personalized quote. Contact Holiday Ice today for expert guidance and seamless procurement, backed by decades of proven performance.