Products

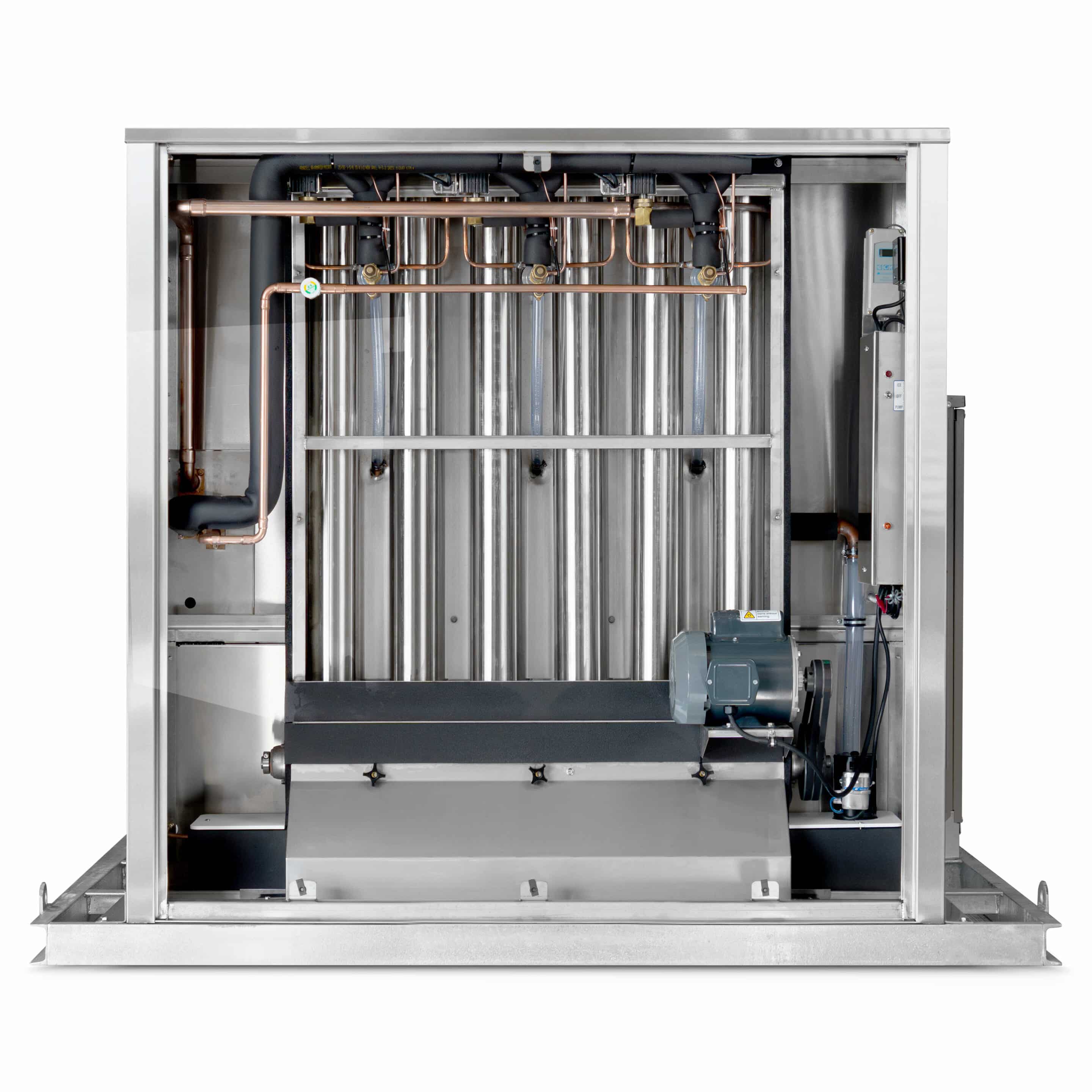

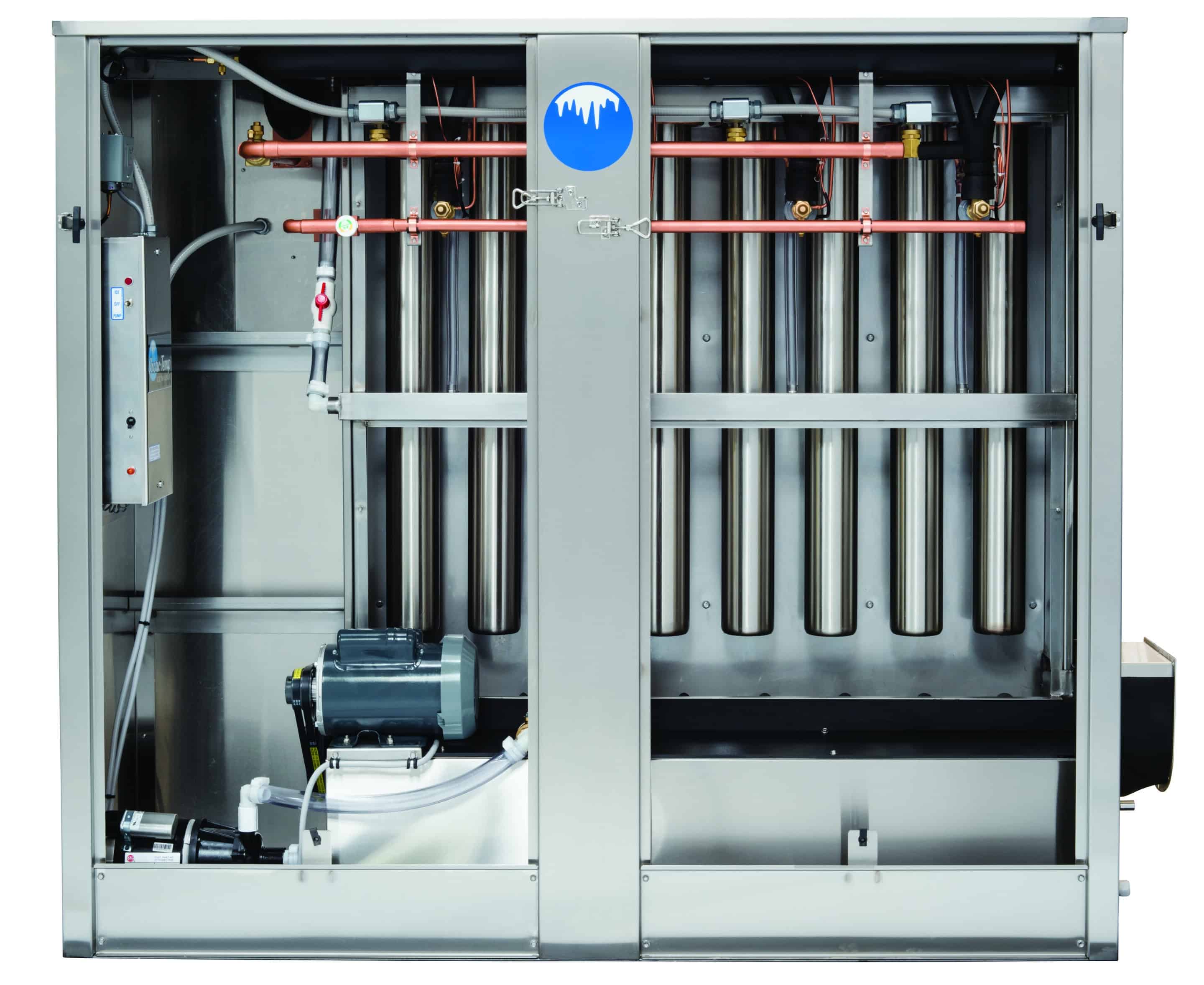

Commercial & Industrial Ice Machines

Holiday Ice Inc. is the leading manufacturer of vertical tube industrial ice machines that embody performance at its best. Our machines are made to be reliable, easy to maintain, and energy and water-efficient.