Arctic-Temp® Ice Makers by Holiday Ice, Inc.

All Purpose Industrial Ice Machines From 2,500 to 10,000 lbs Per Day

Holiday Ice is a manufacturer of specialized, mid-range capacity commercial ice machines for industrial applications. For over 60 years, our commitment to personal service and outstanding quality has created a family of happy customers.

The Best Value

Our machines are efficient, economical, and made from the highest quality material and components, including top-of-the-line Copeland compressors.

Energy & Water Efficient

Our machines use re-circulated water, which saves you money on water costs. They also use less electricity than other models at the same capacity.

Realistically Rated

Our machines operate in Southern latitudes and are realistically rated for maximum performance during the scorching summer months when demand is greatest.

60+

years of experience

Who We Are

Holiday Ice,Quality You Can Count On.

Our Arctic-Temp® Ice Machines are legendary for providing years of reliable performance, even in the most grueling climates and conditions. Holiday Ice is a family-owned business, and we serve our customers with a personal touch.

Personalized Customer Service

Instead of some pre-recorded message, you’ll be greeted by a member of our friendly staff.

Top-Rated Copeland Compressors

No other manufacturer offers our combination of quality, longevity, price and service.

2000 lbs industrial ice machine – Resources

2000 Lbs Industrial Ice Machine

3000 Lbs Industrial Ice Machine – 4000 Lbs Industrial Ice Machine

Buy 4000 Lbs Industrial Ice Machine: Top Commercial Tube Ice Maker for Seafood

Maintaining commercial and industrial efficiency hinges on reliable infrastructure, especially for businesses requiring continuous, high-volume ice production, such as food processors and large hospitality operations. The procurement process often starts with capacity—evaluating options like a 2000 lbs industrial ice machine, the mid-range 3000 lbs industrial ice machine, or the high-output 4000 lbs industrial ice machine—to match specific operational demands. Understanding machine mechanics, cooling capacity, and manufacturer durability is critical to ensuring long-term success and minimizing downtime in demanding environments.

Selecting the Right Ice Maker for High-Volume Requirements

When scaling up ice production, procurement managers frequently ask which machine size offers the best balance of cost, capacity, and reliability. Whether searching for a 2000 lbs industrial ice machine or capacity closer to 4000 lbs, the core essential components remain similar, revolving around a robust evaporator and reliable compressor integration, often utilizing established brands like Copeland. These high volume commercial ice maker units are essential for sectors like seafood and fishery operations where quick, consistent chilling is paramount. For businesses needing reliable mid-range output, the capabilities of a 3000 Lbs Industrial Ice Machine are often a perfect fit, providing professional cooling capacity without the footprint of ultra-large industrial systems.

Exploring Industrial Ice Production Technology

The best choices among high-capacity ice makers often feature a reliable design that emphasizes long operational life and ease of maintenance. A superior approach frequently involves the vertical tube ice machine design, which delivers fast production and maximum heat exchange efficiency. This technology utilizes a double-surface freezing mechanism that ensures 100 percent of the evaporator surface area is used, a key differentiating factor in ensuring high output. Furthermore, industrial ice machine cooling capacity is maximized by eliminating moving parts in the freezing zone, which significantly reduces wear and tear and contributes to a simpler mechanical control system, thereby easing routine maintenance and diagnosis.

Crucial Features for Industrial and Commercial Implementations

Choosing the best unit, whether a 2000 lbs industrial ice machine or higher-capacity options, requires careful evaluation of technical specifications and design features. Businesses in specialized segments, such as those needing an industrial ice machine for seafood, must prioritize durability and machine serviceability to handle continuous operation in harsh environments. Manufacturers specializing in durable, simple designs often integrate standardized components that are readily available from refrigeration wholesalers, dramatically reducing lead times for critical replacement parts. This commitment to maintenance simplicity is often found in commercial tube ice maker models that focus on robust, stainless steel construction.

For operations requiring a significant daily volume, such as those utilizing a 4000 lbs industrial ice machine, looking for specific models with proven industrial reliability is necessary. For example, specific Arctic-Temp models like the 500 SM-L (which can be configured to produce around 2000 lbs or more) or the larger 1000 AR-L are designed with durability in mind. Even for those seeking the capacity of a 4000 Lbs Industrial Ice Machine per day, the reliability built into these systems, including features like pre-tested units shipped at rated capacity, ensures businesses receive maximum value and reduced downtime. The long operational life and simple mechanical control of these commercial tube ice machine systems are essential for institutional kitchens and beverage bottling plants.

Scaling Ice Production: From 2000 Lbs to 4000 Lbs and Beyond

The decision of where to buy an ice machine—and what size—is dependent on future growth expectations and current processing needs. Whether evaluating a 2000 Lbs Industrial Ice Machine for a supermarket or a 3000 lbs industrial ice machine for a larger food processing plant, the underlying production technology should prioritize simple, durable operation. Manufacturers who offer direct factory contact and stocking programs for legacy machine parts reinforce their commitment to serviceability, a key factor often overlooked versus just the initial price.

Procurement managers choosing between a 2000 lbs industrial ice unit and a 4000 lbs industrial ice machine often look towards the simplicity of the mechanical control system. Complex digital controls can lead to diagnostic complexity, contrasting sharply with the reliability offered by systems designed for straightforward troubleshooting. Furthermore, when considering the best vertical tube ice machine, attention should be paid to the total ownership cost, including energy efficiency and parts availability. The consistent quality and performance of a reliable commercial tube ice maker can significantly impact operational overhead. Services supporting units, including phone-based troubleshooting and a well-stocked parts department, ensure that maintenance is efficient and effective, keeping the operation running smoothly, regardless of whether you have a 3000 Lbs Industrial Ice Machine or a higher-capacity unit.

The interconnected requirements for reliable ice production—ranging from the high volume commercial ice maker capacity of 2000 lbs to the sustained needs of a 4000 lbs industrial ice machine—all converge on the need for simplicity, durability, and support. Seeking out manufacturers known for robust construction, readily accessible parts, and vertically suspended double-surface freezing technology ensures investment protection and optimal performance. This integrated approach to procurement and maintenance guarantees long-term success across various industrial applications.

Additional Resources:

Wedding Catering Louisville

ChefsPrep Catering

502-821-3274

chefsprepmeals.com

As a premier catering company in Louisville, we at ChefsPrep Catering understand the importance of creating an unforgettable culinary experience for your wedding day. Our team is dedicated to crafting unique menus that reflect your love story and culinary dreams, ensuring that every bite is a taste of perfection. From intimate affairs to grand celebrations, we collaborate closely with our clients to meticulously plan and execute every detail of the catering experience. Our commitment to flexibility, diversity, and sustainability sets us apart, allowing us to design menus that cater to specific dietary requirements, cultural considerations, and theme preferences. With a…

Donut Shops in Colorado

Check out I Live Donuts when you’re looking for donut shops in Colorado that are close to home. Colorado Springs is home to one of our most popular donut shops, with your favorite donuts made fresh every morning. Don’t settle for a second-class donut when we have the best donuts in America for every special occasion.

Best Dispensary in Massachusetts

DDM Cannabis | Blackstone, MA Dispensary

What is it about DDM Cannabis that makes our weed store the best dispensary in Massachusetts? Mandatory social distancing is one great reason to shop in-person at DDM Cannabis; you can also order online and pick up at your convenience. Browse our extensive cannabis inventory online to see strains, pre-rolls, concentrates, and more. DDM Cannabis | Blackstone, MA Dispensary

What We Offer

OurIce Machines

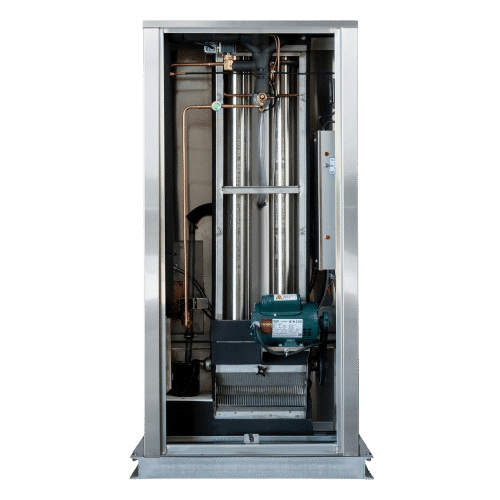

ARCTIC-TEMP® MODEL 500

- 2,500 lbs. of hard cracked ice in 24hrs. (907 Kg.)

- Highly efficient Copeland Compressor

- Double-Walled Vertical Tube Evaporators For Maximum Production

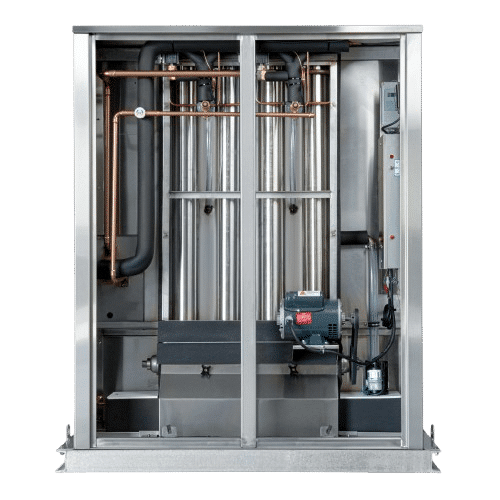

ARCTIC-TEMP® MODEL 750

- 4,500 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

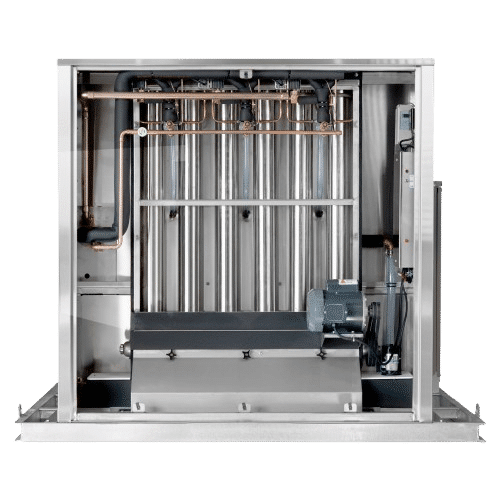

ARCTIC-TEMP® MODEL 1000

- 6,500 lbs. of hard cracked ice in 24 hrs. (2,948 Kg.)

- Highly efficient Copeland Discus Compressor

- Double-Walled Vertical Tube Evaporators

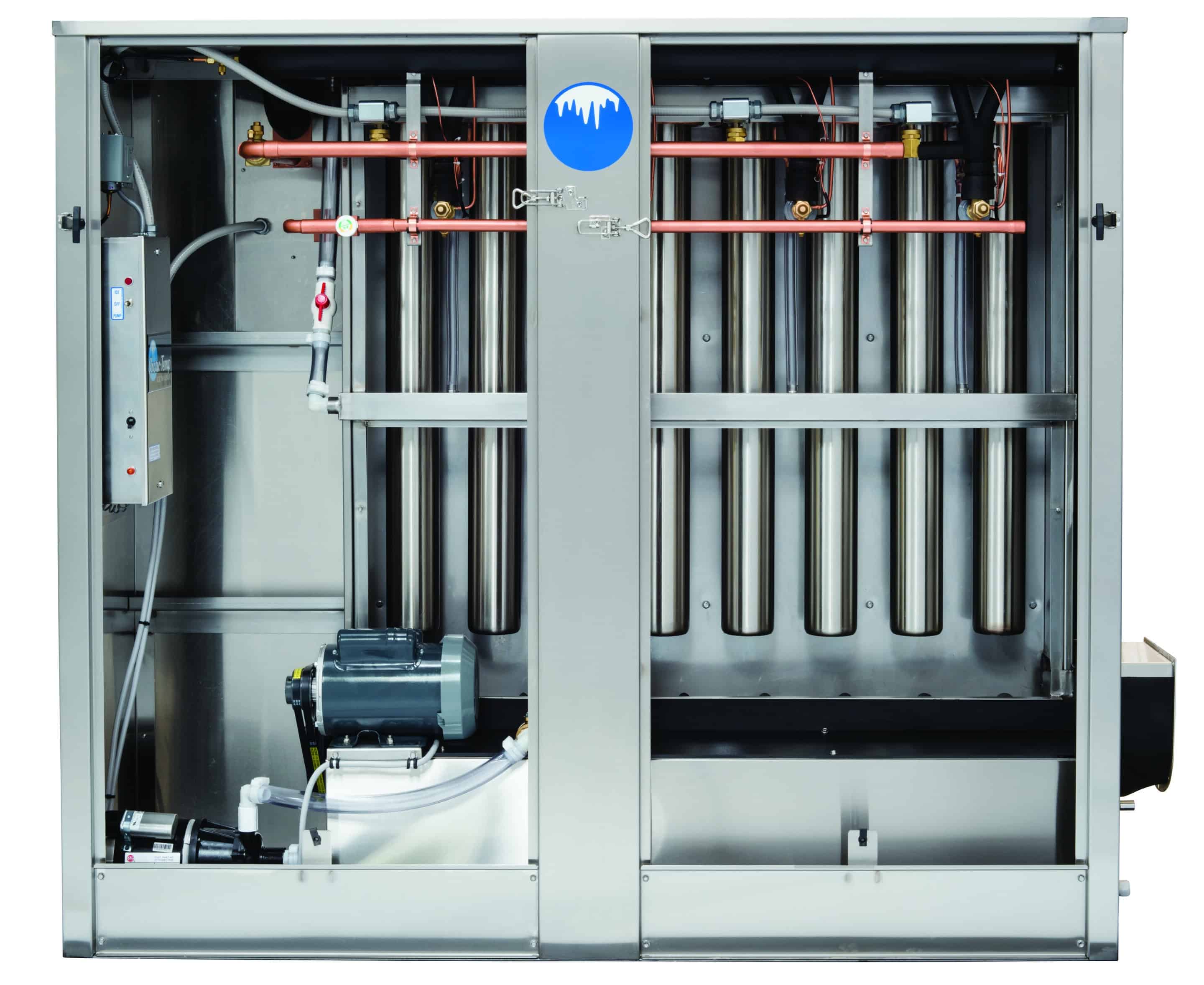

ARCTIC-TEMP® MODEL 1500

- 10,000 lbs. of hard cracked ice in 24hrs. (4,536 Kg.)

- Low-temperature Copeland compressor for maximum production

- Larkin RCU with “Floating Coils” for long life

Ice Machine Manufacturing

ProductionProcess

- Our ice machines are built using high-quality Type-304 stainless steel, unlike other companies that use lower-grade alloys.

- Machines are hand-assembled and TIG welded for precision.

- Stainless steel evaporators are hand-formed and welded for durability.

- The ice-making section is fully assembled before being combined with the condenser and compressor.

- We use COPELAND compressors, known for their quality, industry-leading warranty, and widespread parts distribution.

- Our evaporators use a double-surface concave freezing technique with vertical tubes for faster, more efficient ice production and improved cooling.

- The freezing zone contains no moving parts, avoiding issues related to gears or motors.

- Standard, easily replaceable components are used, except for the evaporator, which simplifies maintenance after the warranty period.

- All machines are leak and vacuum tested, factory charged with refrigerant, and thoroughly calibrated for reliable performance from the start.

Years in Business

Ice Machines Sold

Repeated Customers

Countries Served

Global Network

CountriesWe Serve

North America

- • USA

- • Canada

- • Mexico

- • Bahamas

- • Anguilla

- • Cayman Islands

- • Jamaica

- • Dominican Republic

- • St. Lucia

Central America

- • Belize

- • Honduras

- • Nicaragua

- • Guatemala

- • El Salvador

South America

- • Guyana

- • Suriname

- • Ecuador

South America

- • Guyana

- • Suriname

- • Ecuador

Aruba

Iceland

Philippines

Oceania

- • American Samoa

- • Australia

Client Reviews

Testimonials

Discover firsthand experiences from our satisfied customers about their Arctic-Temp® ice machines.